Additive Manufacturing

Additive Manufacturing Solutions That Deliver Precision and Speed

Additive manufacturing, commonly known as industrial 3D printing, is transforming the way products are designed, prototyped, and produced. At MWES, we leverage this cutting-edge capability through ADDere’s proprietary directed energy deposition (DED) technology to deliver complex, high-performance, mission-critical parts with speed and precision. From rapid prototyping to full-scale production, our solutions eliminate the limits of traditional manufacturing

Print Large-Format Parts

Print Large-Format Parts

Build components several meters in size—ideal for aerospace, defense, and energy sectors.

High Deposition Rates

High Deposition Rates

ADDere is engineered for high-throughput metal additive manufacturing, reducing build times for large structures.

Wide Material Compatibility

Wide Material Compatibility

Supports a variety of metal alloys, including titanium, stainless steel, Inconel, and other industrial-grade materials.

Our Additive Manufacturing Capabilities

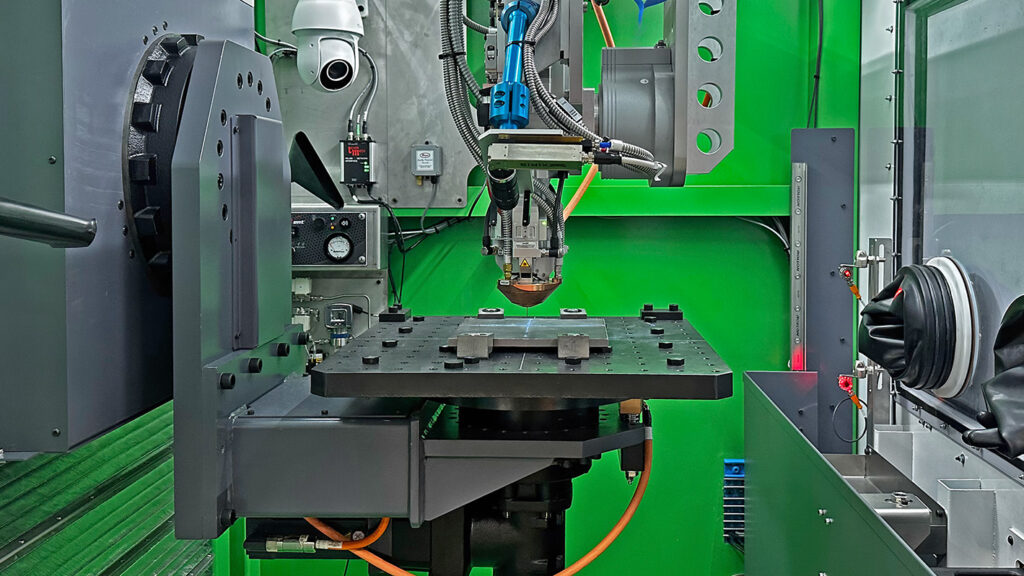

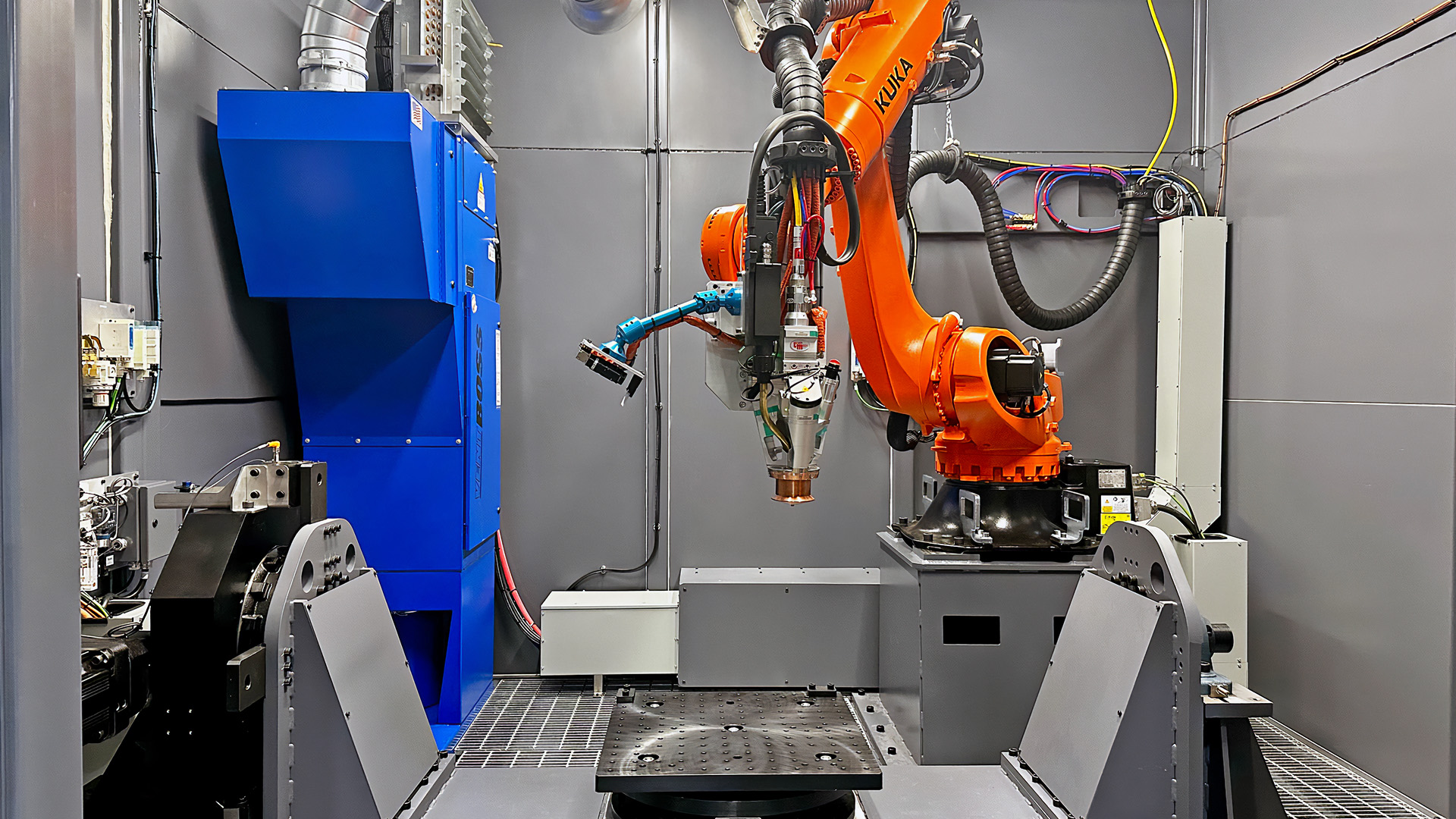

ADDere Additive Manufacturing is a Laser Wire Additive Manufacturing (LWAM) system designed for large-scale, high-strength metal components. Using a high-powered laser with a pre-heated wire feed, it delivers clean, precise layers with excellent structural integrity—ideal for mission-critical applications.

Unlike fixed gantry systems, ADDere uses a 6-axis robotic arm with additional external axes for greater flexibility, accuracy, and the ability to create complex geometries with multi-angle deposition.

A closed-loop sensor package continuously monitors and adjusts the process in real time, ensuring consistency, tight tolerances, and repeatable results even on massive parts.

Whether you’re producing near-net shape parts, tooling, or legacy component replacements, ADDere provides a scalable, cost-effective alternative to traditional subtractive and cast metal processes.