Automated weld analyzing systems can be integrated into robotic welding cells to track weld performance in real-time or the inspection process can be completed as its own stage after the weld...

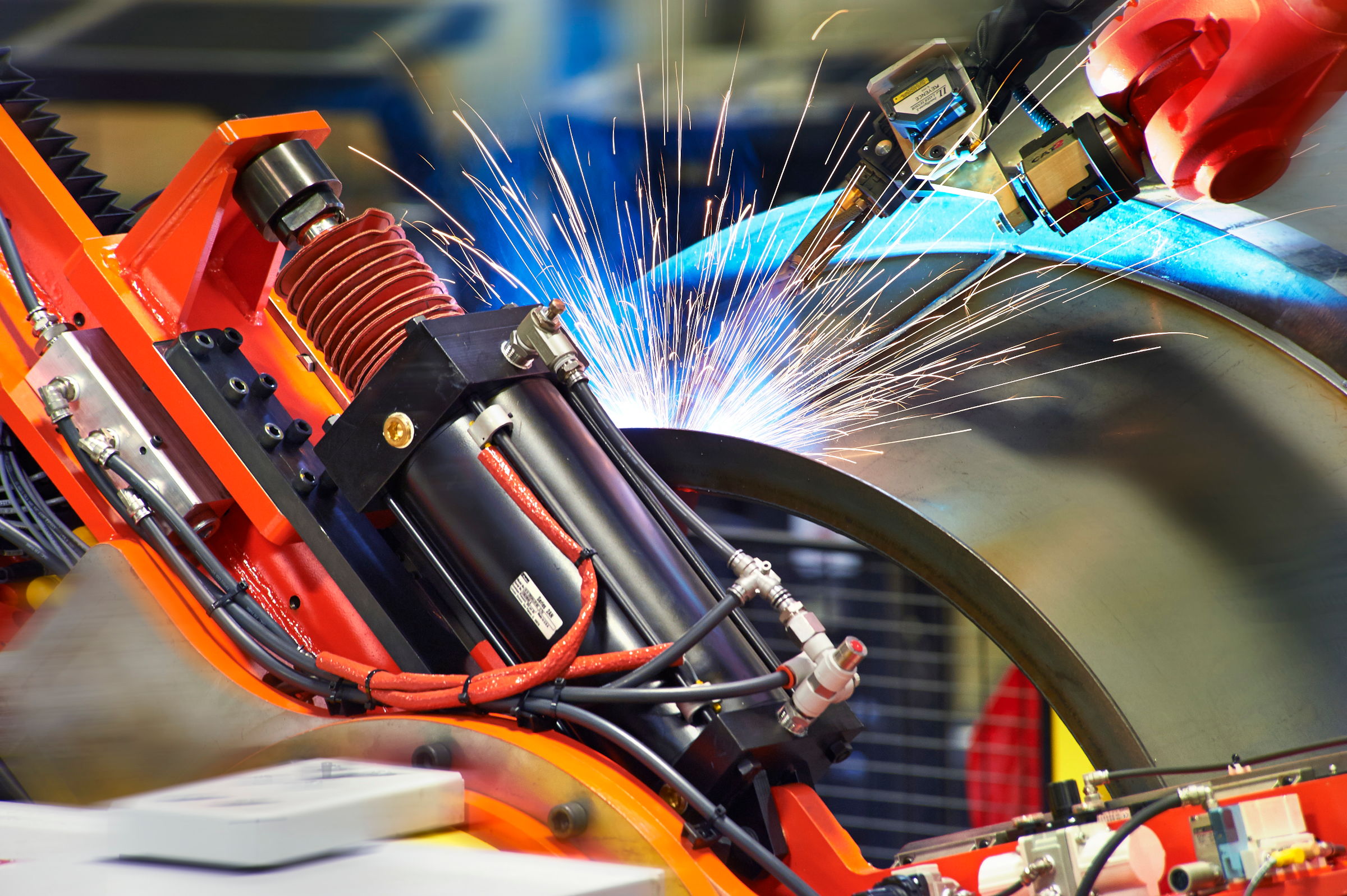

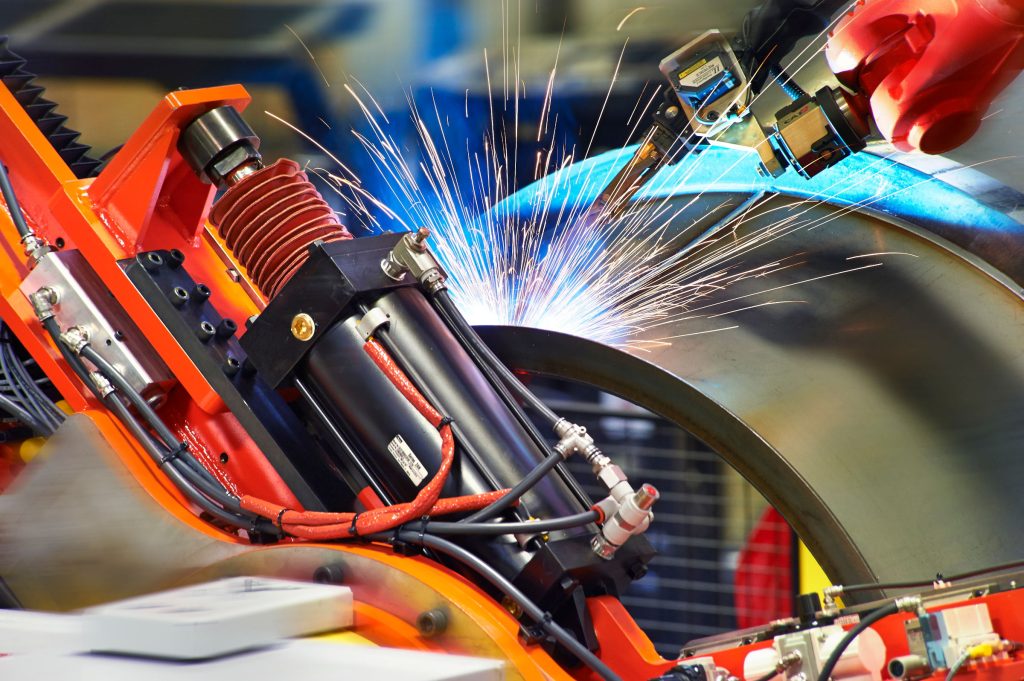

Midwest Engineered Systems Easy-Arc Collaborative Robot Welding systems were created to supplement the abilities of human welders with industry-leading performance.

Our team of welding automation experts draws on more than 30 years of experience in cutting-edge welding design, development, and programming. When it comes to developing specialized welding...

INNOVATION THROUGH AUTOMATION

Home Industrial Automation Capabilities Robotic Welding Easy-Arc FW Laser Weld Cell

EASY-aRC Welding...

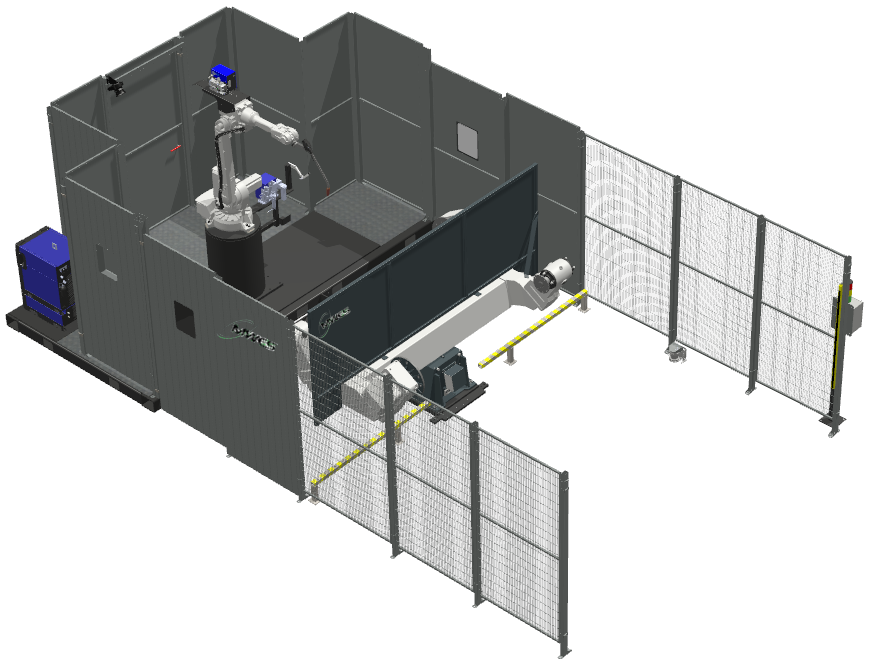

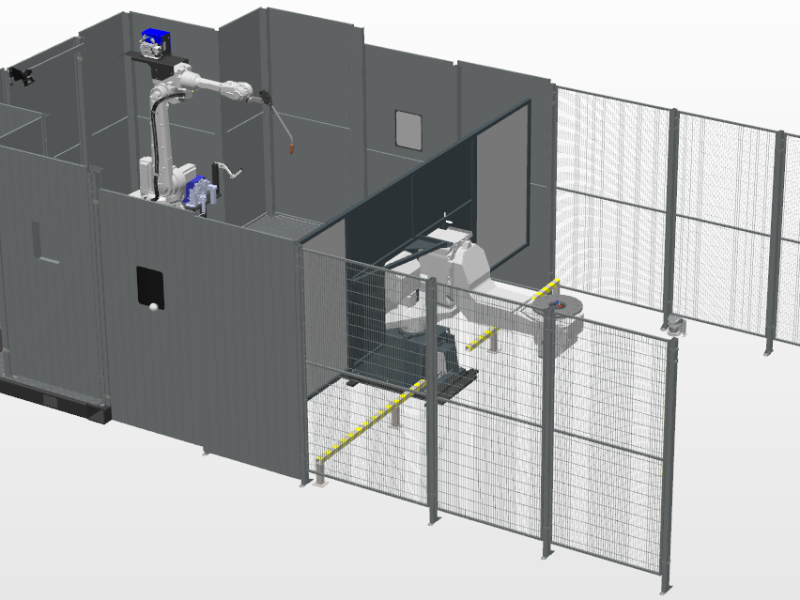

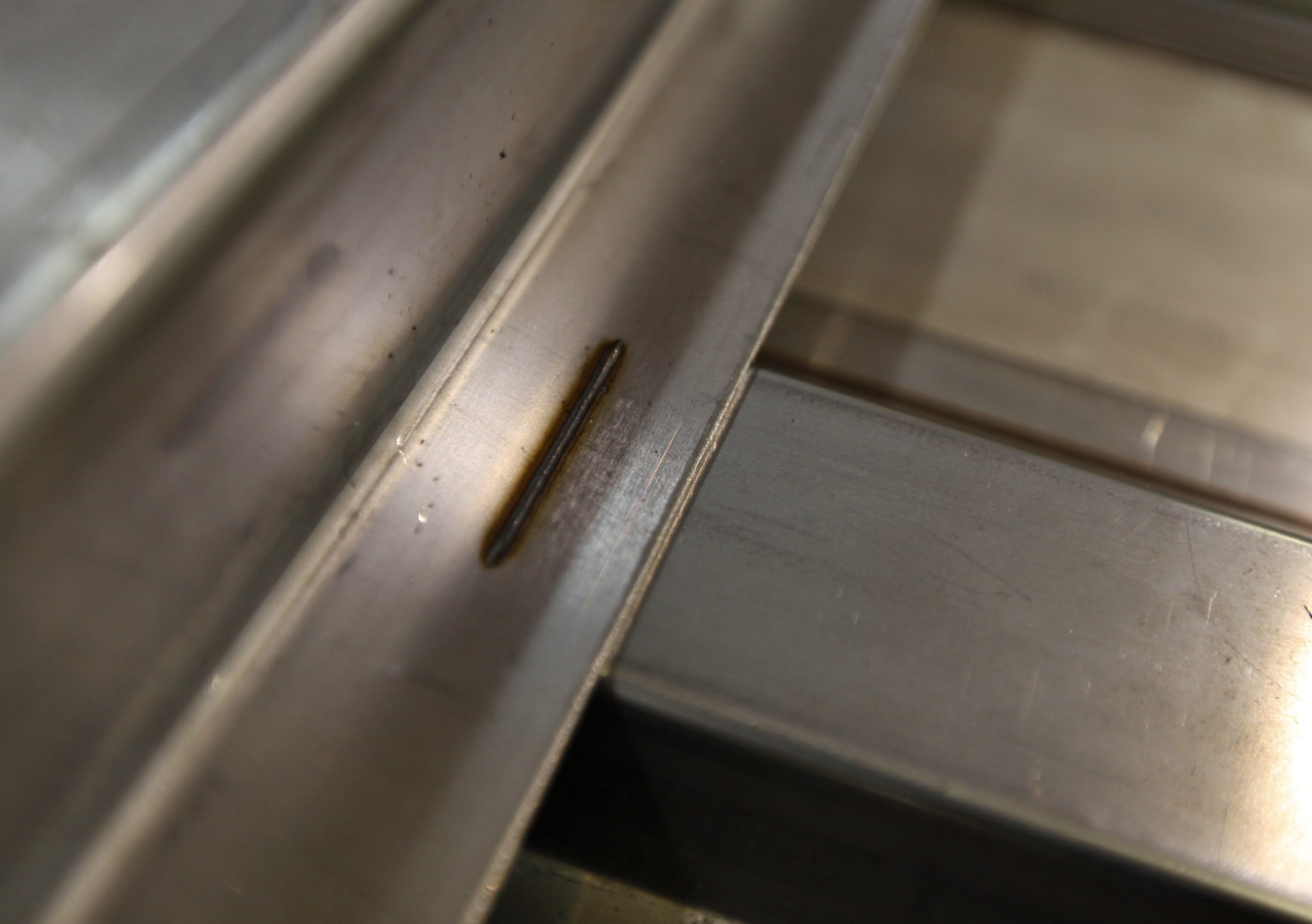

The MWES Easy-Arc HW Laser Cell is an easy-to-use, fully-enclosed compact fully automated robot welding system.

Easy-Arc Laser Welding System’s purpose is to give the absolute best in terms of high quality, dependable performance, and cost considerations in a fully-enclosed work cell.

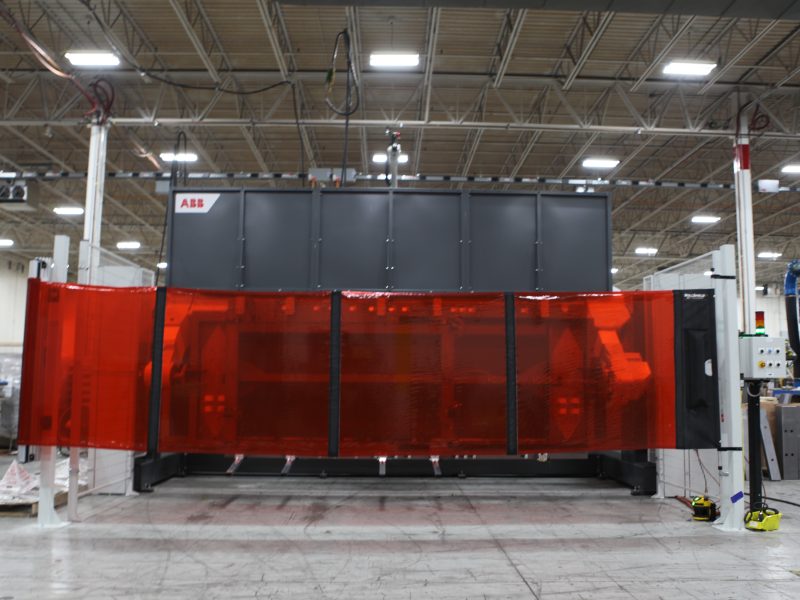

Standard, robotic arc welding cells offer the best combination of price and performance. MWES provides complete robot systems, available in several flexible, modular packages.

The Indexing 2-Axis Positioner Cell comes with a full range of safety features and can accommodate two robots. The loading zone of the cell is available in two variations: roll door or light...

The Indexing Ferris Wheel Cell comes with a full range of safety features and can accommodate two robots. The loading zone of the cell is available in two variations: roll door or light curt...

The Indexing H-Frame Cell comes with a full range of safety features and can accommodate two or three robots. The loading zone of the cell is available in two variations: roll door or light ...

The standard Indexing Cell comes with a full range of safety features and can accommodate up to three robots. The loading zone of the cell is available in two variations: roll door or light ...

The MWES Easy-Arc TC300 Weld Cart utilizes a collaborative robot which is an industrial robot arm designed for operator safety, ease of use and programmability.

Weld positioner systems place welding parts in optimal positions even in some of the most challenging applications.

The two most common types of gas arc welding are Gas Metal Arc Welding (MIG) and Tungsten Inert Gas Welding (TIG).

Demand has increased in recent years for high-strength, heavy-gauge steel. This is particularly the case for large-scale construction projects.

In the heavy fabrication industry creating welded parts requires welds that have a heavy deposition rate to create stronger components.

With standard integrated weld systems, the welding automation machinery is designed to specialize in just one of the processes.

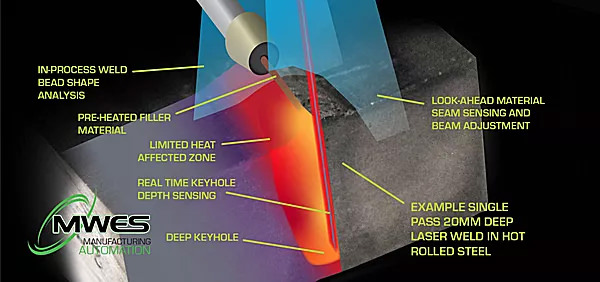

Laser hybrid welding is a process that uses a combination of laser and wire arc welding systems. Combined, these processes build on each’s strengths while reducing their weaknesses.

Multi-process automated welding systems maximizes speed, output and accuracy, particularly for challenging welds. MWES can integrate a variety of multi-process welding setups.

This welding process also allows both similar and dissimilar materials to be welded together with no shielding gasses or fluxes.

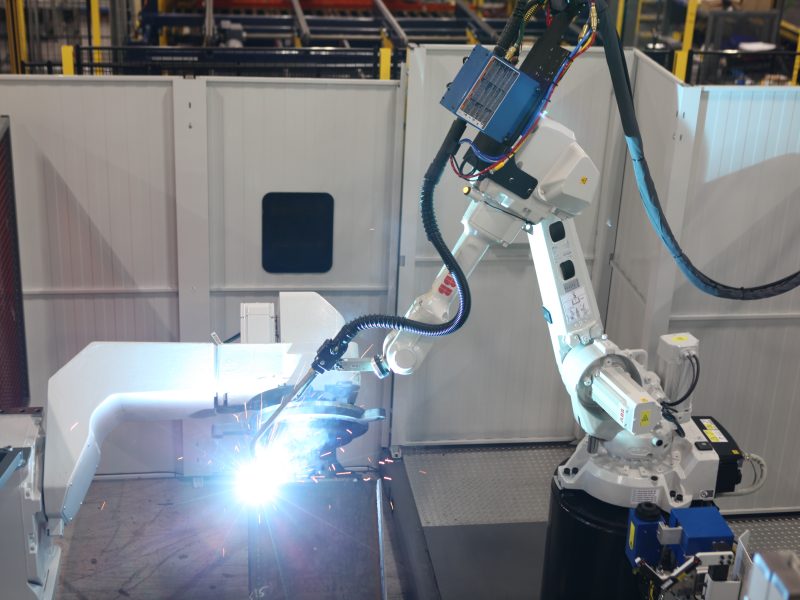

Traditionally, all arc welding work had been done with manual labor, however, over the last several decades more and more arc welding work has been transitioned over to robotic automation.

This form of welding creates a strong enough bond in the workpiece that makes it fluid and gas tight.

The tandem welding process consists of two electronically isolated wires, two separate power sources and two feed units.

All of these processes are compatible with robotic automation and combined with robot vision systems, these processes are unmatched.

Newer technology has the potential to improve equipment reliability, weld quality and overall throughput for your operation.

One of the most important keys to success in designing and building automated welding systems is the ability to properly hold pre-tacked assemblies or capture multiple components for welding....