Surface Treating Systems

- Home

- Industrial Automation Capabilities

- Robotic Automation Systems

- Surface Treating Systems

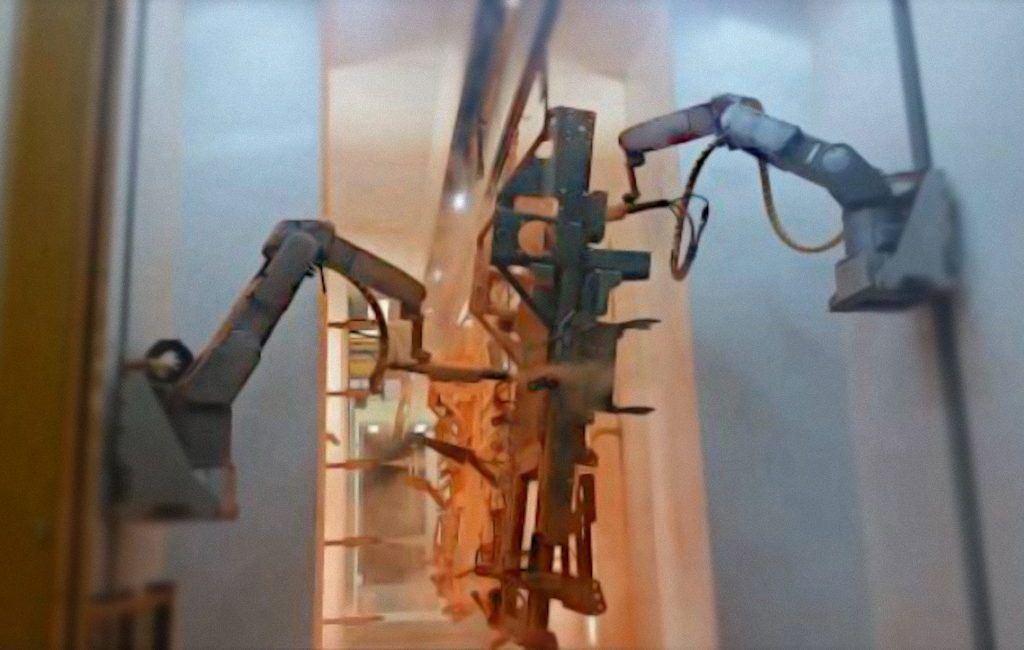

Perform Your Surface Treatment Process Fast & Accurate with Robots

Surface treatment is used to clean, etch, and functionalize surfaces to improve adhesion to a wide variety of plastic and metal surfaces. Just like most automation systems, the use of robotics and automation in the realm of industrial surface treating has benefits such as increasing productivity, safety, flexibility, and efficiency while reducing production costs.

In most cases, automating the material handling aspect of the surface-treating processes is necessary to achieve throughput goals. This is especially true in large-volume industrial manufacturing situations. Some of the areas that MWES has surface treating experience in are printing, coating, bonding, labeling and heat treating.

Automating Surface Treatment

Just like most automation systems, the use of robotic automation in the realm of surface treating has benefits such as increasing productivity, flexibility and efficiency while reducing production costs. In most cases, automating the material handling aspect of the surface-treating processes is necessary to achieve throughput goals. This is especially true in large-volume manufacturing situations.

Painting

Coating

Bonding

Printing

Labeling

Robotic automation is rapidly becoming a crucial component of an already evolving world. High-performing robotic surface treating can be semi or fully automated and custom-built for your treatment requirements. The automation products Midwest Engineered Systems provides can elevate your business to new heights. Contact us today if your business is looking to expand its surface-treating production capacity or to move away from the rigors of a manual labor workforce.

Building the future of manufacturing, together

World-class Automation