Assembly Automation

- Home

- Industrial Automation Capabilities

- Assembly Automation

Bringing process together with

Automated Assembly Solutions

We can Automate your Assembly Process

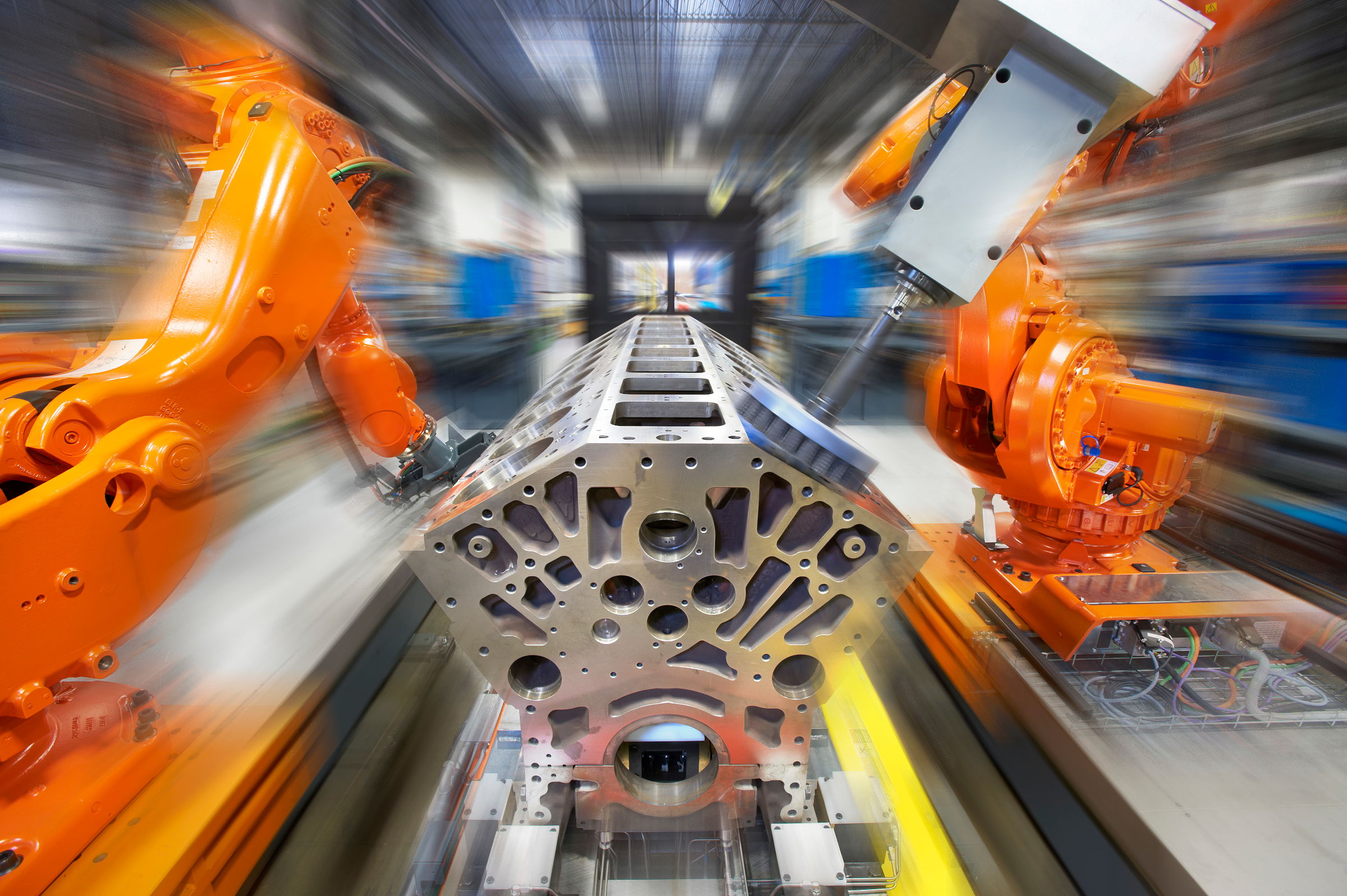

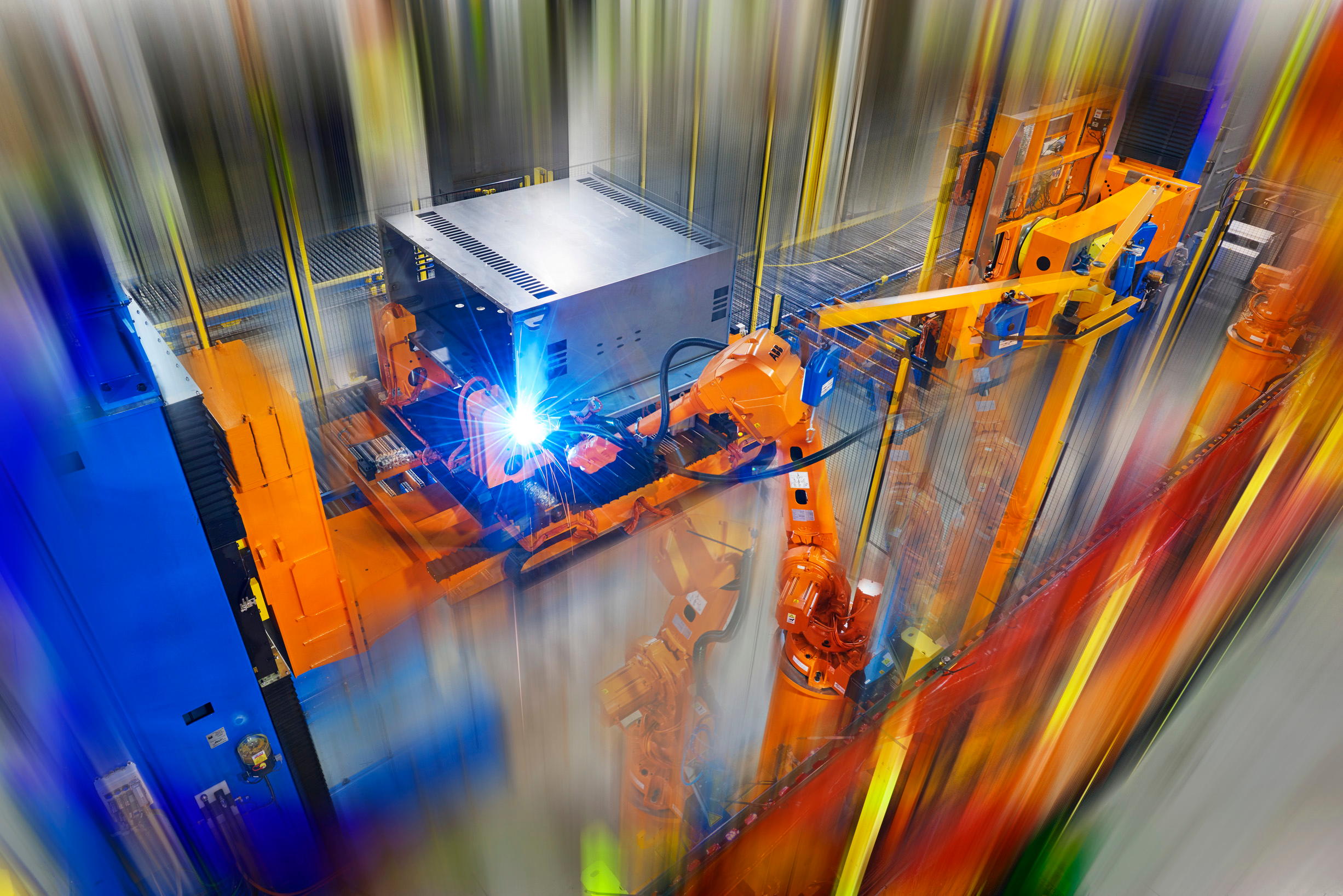

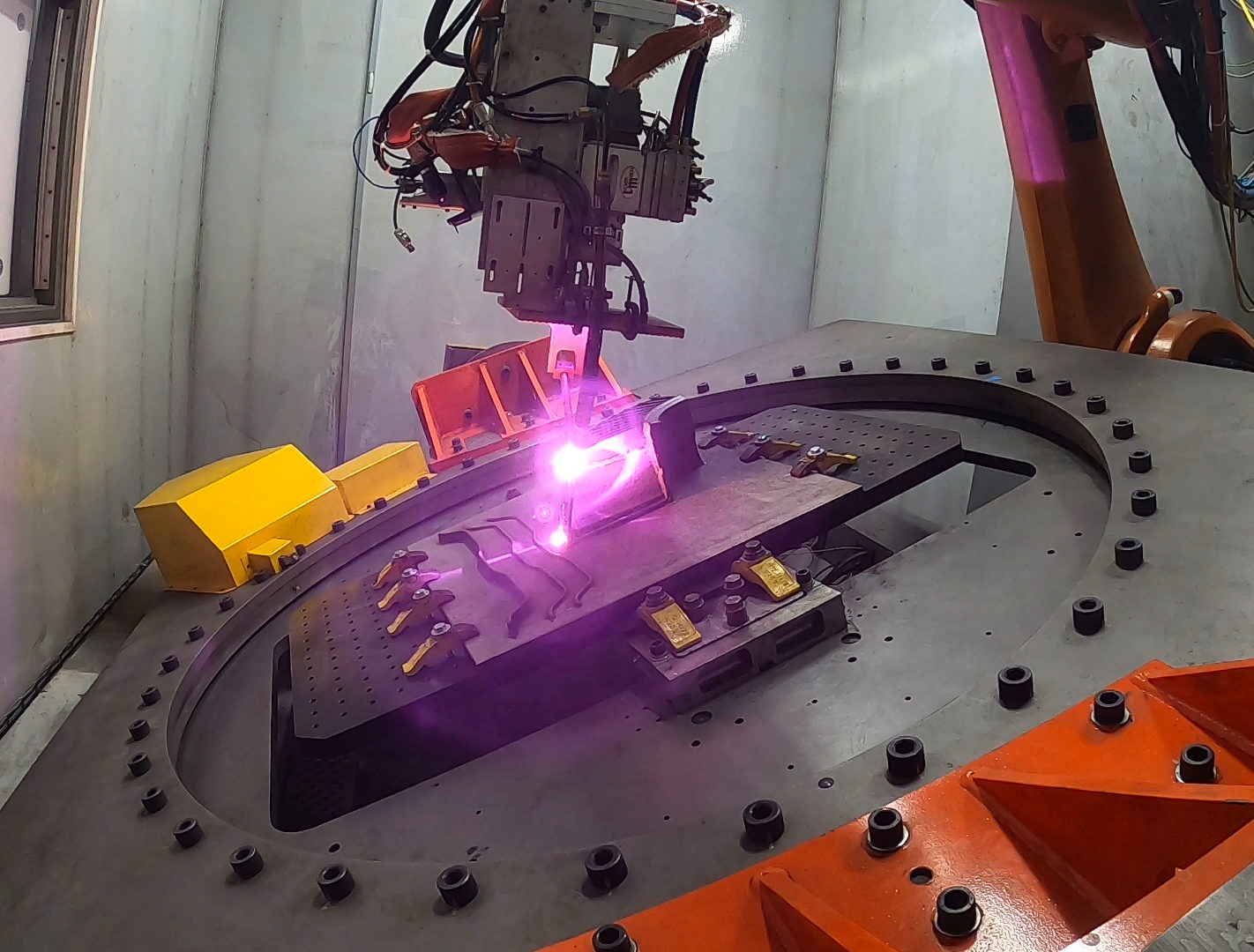

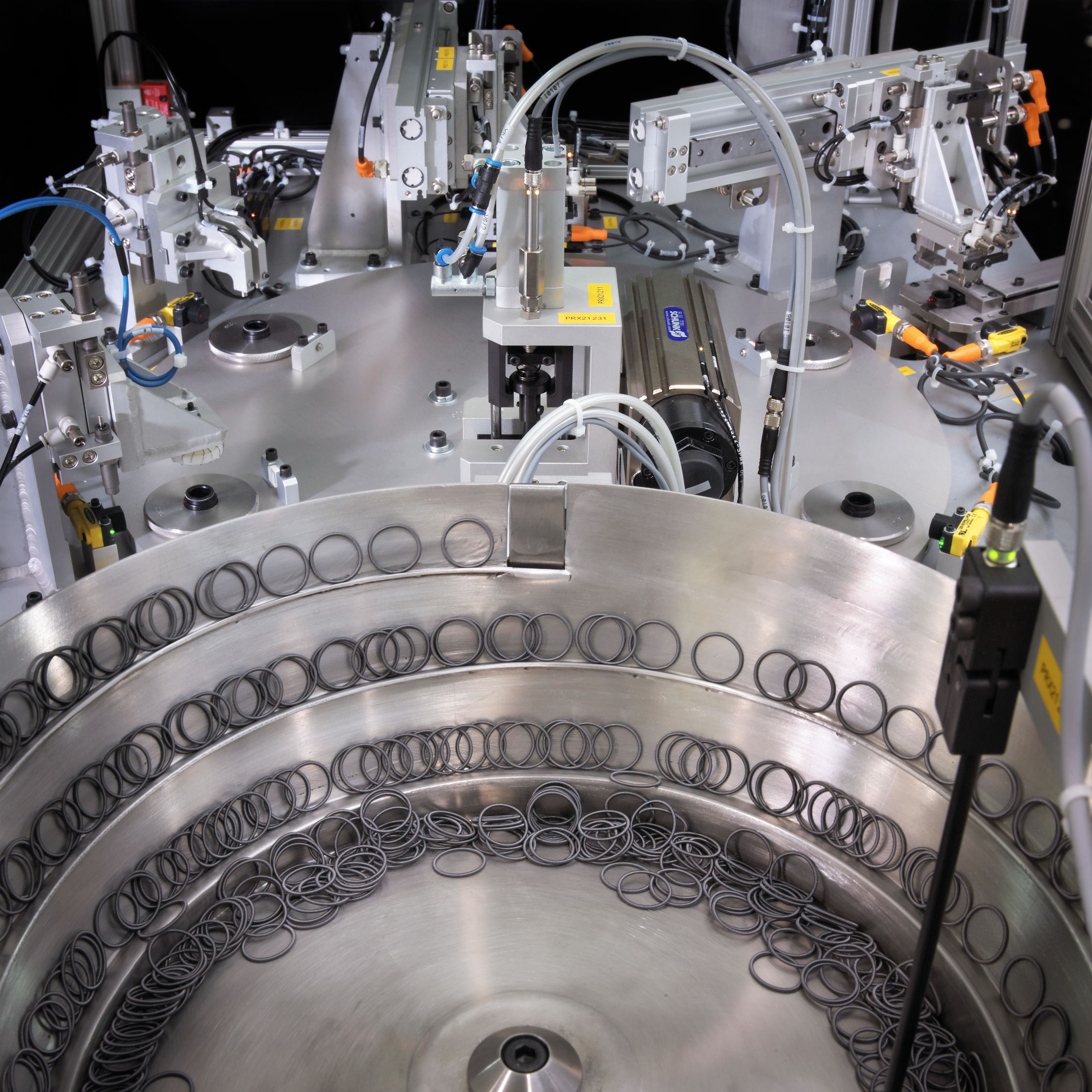

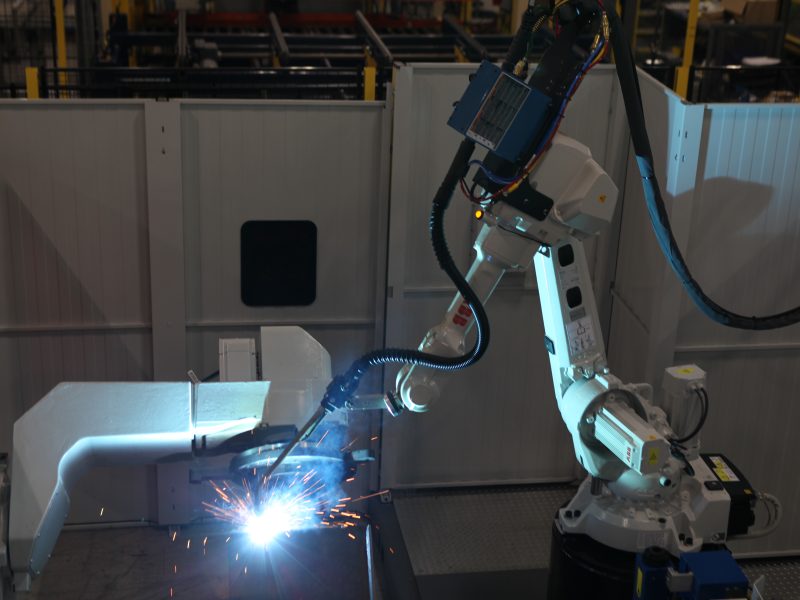

Industrial-scale automation in the 21st century is rapidly changing. With the current labor shortages along with rising labor costs, switching to robotic assembly automation has become a crucial next step for a lot of businesses. Midwest Engineered Systems has spent decades integrating automation products into existing production lines for businesses large and small. These automation solutions have provided our customers with increased production throughput, improved reliability and a great return on investment.

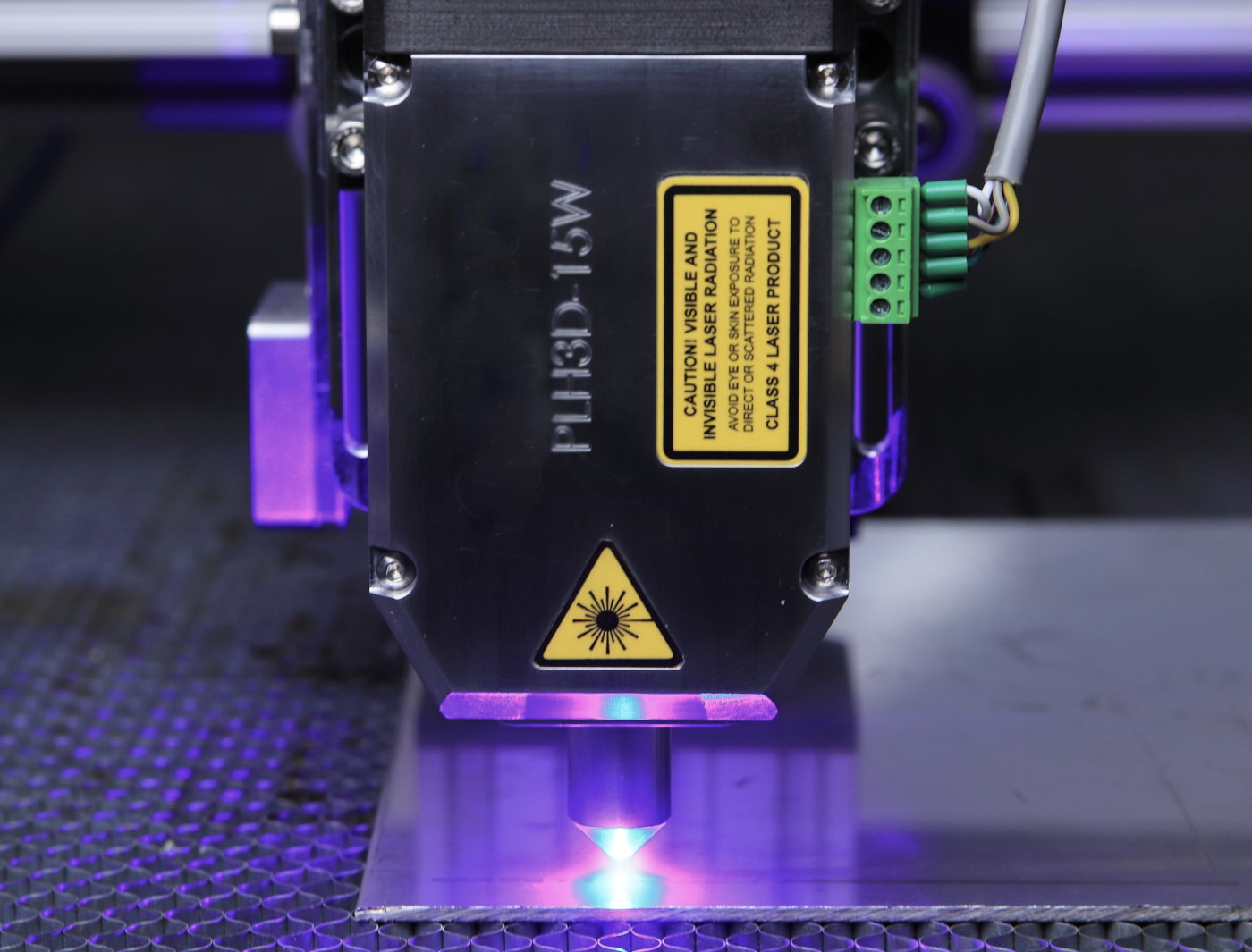

Automation has become a pillar in today’s production environments. With the physical demands required of material handling work and the lack of highly skilled labor to perform challenging work such as welding operations, many businesses are turning to automation technology in order to grow their operation. From palletizing to case packing to machine tending, MWES has the experience and knowledge in providing integration of a wide range of complicated automated solutions.

Components of Automation Technology

Building the future of manufacturing, together

The Areas where we can Help