High-Speed Vision Inspection Systems

- Home

- Industrial Automation Capabilities

- Robotic Automation Systems

- High-Speed Vision Inspection Systems

Inspect Your Processes with High-Speed Vision Systems

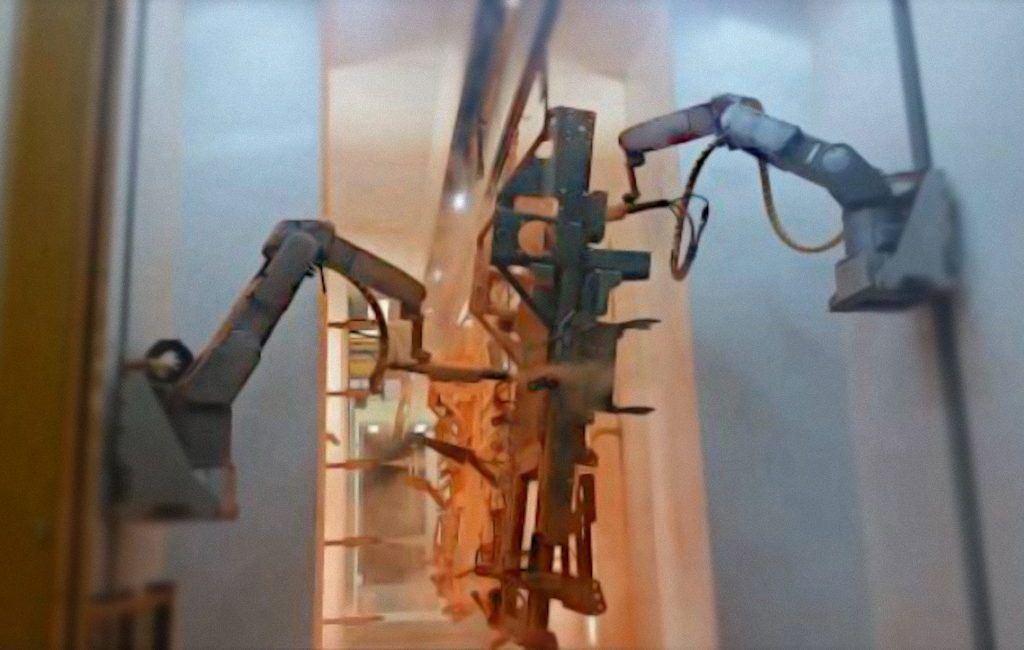

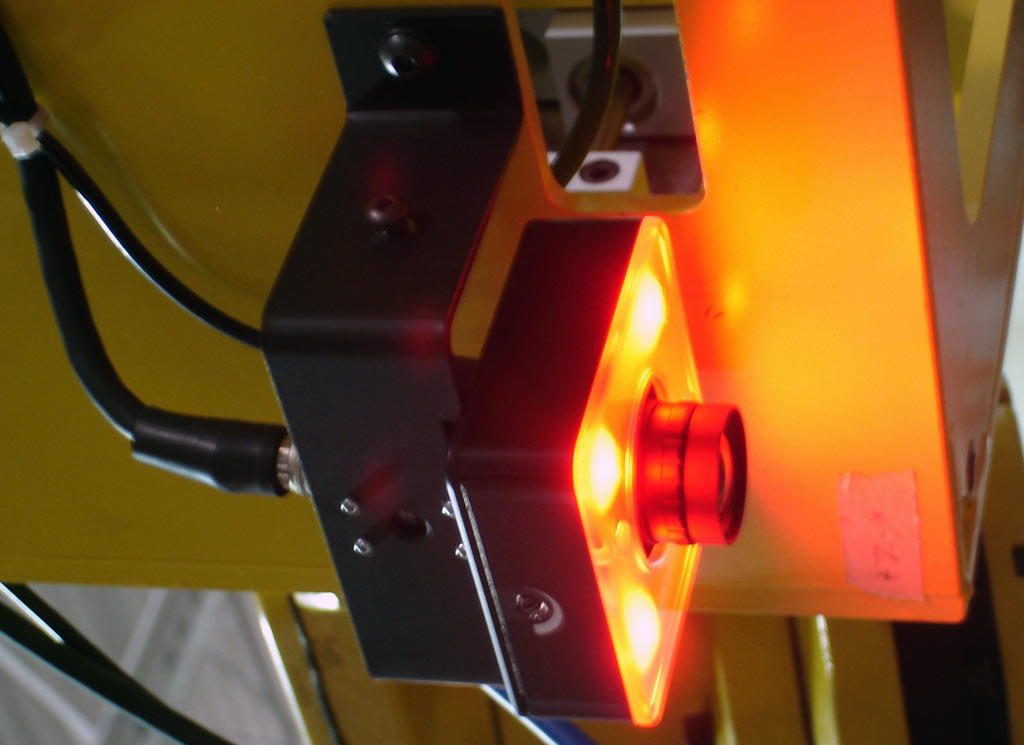

Vision systems display high-speed 2D or 3D maps of the manufacturing environment to assist robots in picking, placing, orienting, controlling, etc. which will improve throughput and consistency. Additionally, with the help of vision systems, they can verify parts for accuracy for quality control purposes.

Midwest Engineered Systems routinely utilizes high-speed vision inspection equipment in our manufacturing automation systems to fulfill our customers’ process needs. High-speed vision systems are sophisticated enough to eliminate the need to manually inspect and measure materials as they cycle through a system.

Track Defects & Part Variances with Vision Inspection Systems

MWES builds and implements systems that take advantage of vision systems. Utilizing these systems provides our customers with greater cycle times and a great ROI. By using automated high-speed inspection vision systems, materials can be quickly and accurately checked for consistency in the production line. MWES’ inspection systems are custom-designed to incorporate different handling and feeding concepts for almost any part style.

Building the future of manufacturing, together

World-class Automation