Trigger & Bottle Assembly System

- Home

- Recent Projects

- Trigger & Bottle Assembly System

Project summary

MWES designed and integrated a fully automated system that assembles plastic sprayer bottles with triggers.

The Challenge

Mass assembling plastic sprayer triggers and bottles requires several steps to complete. To meet the demand for their products, this firm sought out MWES to provide an automated solution to their bottle and trigger assembly line.

The Solution

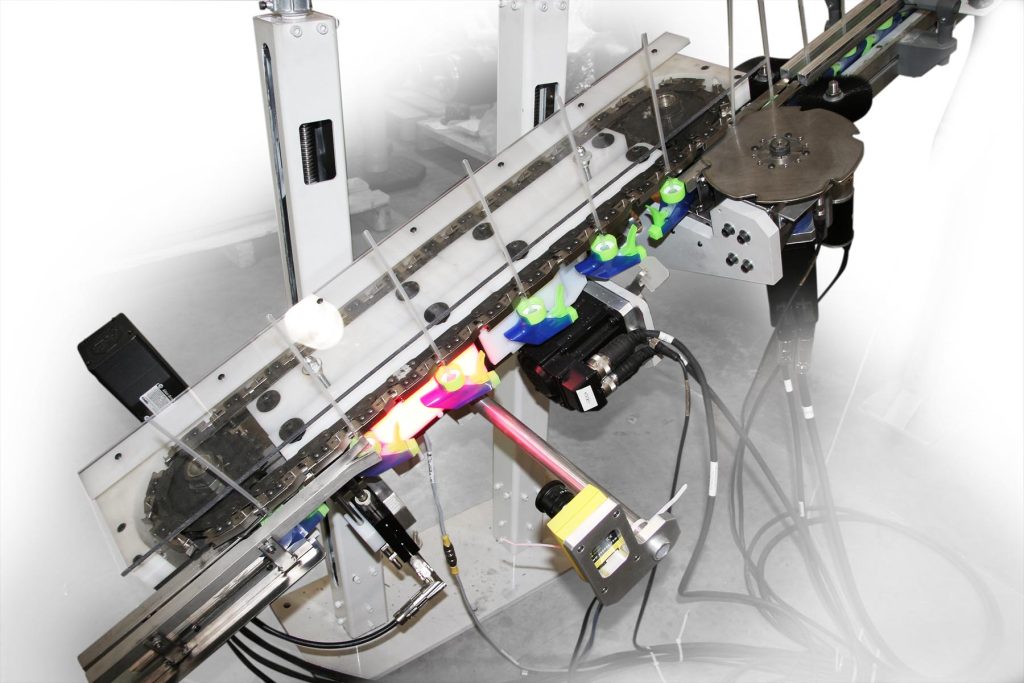

MWES provided our customer with an automated assembly line that would receive multiple types of triggers from a parts washer on a conveyor. The triggers are oriented and then torqued onto the bottles within the specifications. Lastly, the triggers are ultrasonically welded to the bottles for extra security.

The following methods, components and technologies were implemented and integrated to provide a comprehensive solution:

- Trigger hopper and flighted conveyor system control trigger introduction

- Dynamic trigger picking and orientation using robotics and vision

- Dynamic trigger placement using robotics

- Full dynamic bottle sortation using LinMot linear actuators

- Bottle transportation using a custom plastic chain-type conveyor

- Bottle control using dual servo feed-screw control

- Trigger closure torque control using custom servo torque head

Impact to the Customer

The fully automated system MWES provides our customer assembles bottles at a rate of 5 seconds or less. This automated system allowed the manufacturer to automate an otherwise complicated process.

Midwest Engineered Systems has a wide range of experience in building automation systems. If you’re looking to improve your overall throughput, we have the knowledge and experience to make the project a success.

Contact us to learn about how Midwest Engineered Systems can automate even your most complex and challenging operations today!

Innovation Through Automation

Client Details

A multi-national manufacturer of household cleaning supplies.