Process Development

- Home

- Our Process

- Process Development

Teaming Up With Our Customers to

Link the Divide Between Design and Production

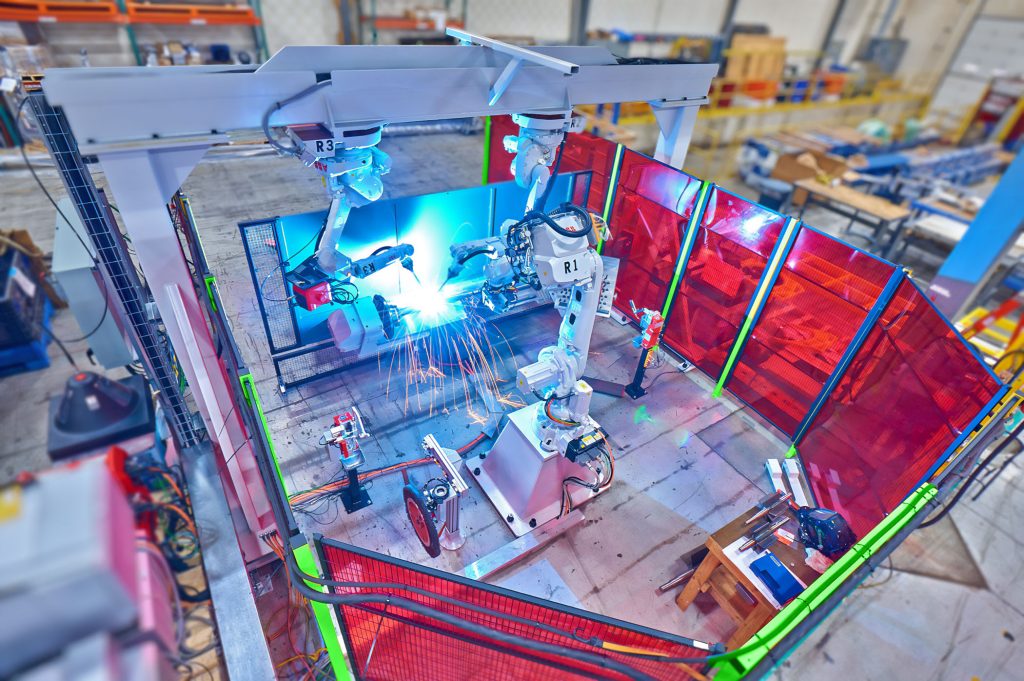

Midwest Engineered Systems has been developing automation systems for over 30 years for many industries and production processes. This diversity of experience provides MWES with the ability to arrive at unique process solutions that translate to greater throughput and quality without sacrificing uptime and dependability. While our knowledge and experience may be broad, our success comes from singularly focusing on our customer’s goals and requirements.

Our approach to automation process development is to first evaluate the firm’s current production operation and understand the company’s process needs. MWES further evaluates the manufacturing system’s speed, quality, and other process metrics. While the former comes from discussions with the customer and a detailed analysis of the request for quote (RFQ), the latter usually starts with an on-site visit with our automation engineers to understand, in person, how the current process works at the floor level, as well as a detailed collection of information and materials.

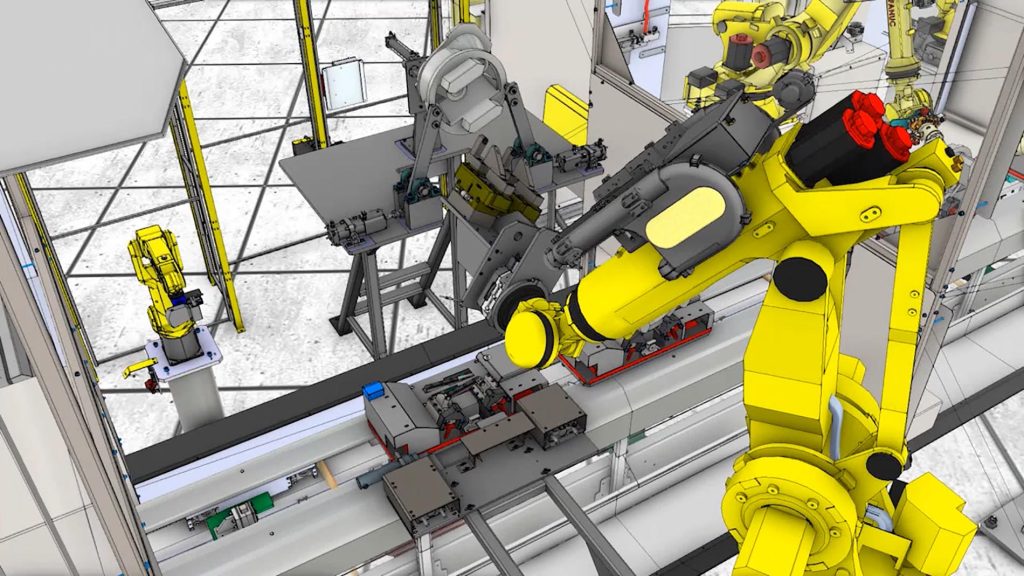

As a true partner in the automation process, we work with our customers to establish attainable requirements, goals, and risk thresholds for a potential automation system. Midwest Engineered Systems then takes these specifications and develops a new prototype production automation process to address them. Our engineers work to develop innovative solutions that combine both the automation industry’s best-purchased hardware with in-house custom-designed automation, to solve your production challenges.

Typically, two to three options are developed by our engineering team for the project. These are presented to the customer for evaluation. Simulations of the system’s performance can be built to provide highly accurate estimations of its potential performance. While it is our preference to rely on proven operations and hardware, newer processes can be tested and analyzed using our proof of principle process to determine if the operations meet the requirements such as up-time, throughput rates, quality, and process capability requirements.

After arriving at a consensus with the customer, Midwest Engineered Systems moves toward the development of a turnkey production line that both MWES and the customer feel confident in its operation and performance. Then a formal fixed bid is submitted to the customer that breaks down the project cost and a detailed overview of materials used, project timelines and agreed-upon machine performance. Then it is up to the customer to accept the bid and MWES moves to build the automation system.

Ways process development can improve manufacturing

- Reducing product cost

- Reducing equipment cost

- Improving process quality

- Increasing process speeds and consistency

- Improving overall equipment performance

Process Improvements on Existing Systems

Many times, a production automation system does not need to be completely replaced, but a detailed analysis of the system’s performance can yield cost-effective changes that can boost its performance. Midwest Engineered Systems can provide production line analysis services using its process development experience to help determine where efficiencies can be found. Process Improvements include evaluation of current equipment capability and determination for implantation of new sensors, controls, and methods to improve manufacturing.

System Controls Updates

Modern production systems come with improvements like finer, more efficient process control and data acquisition that lead to better overall performance. These improvements can usually be made by legacy systems through a carefully considered retrofit roadmap. Process improvements are offered to optimize your current equipment to improve functionality and increase the life of your system. These improvements typically involve custom-developed software and current control hardware that improves tasks and processes. MWES offers these services as well. Our application engineers can guide customers through the landscape of new technologies to arrive at a plan to upgrade a production system to the latest in capabilities.

The benefits of process improvements and control updates

- Increased return on investment (ROI)

- Lower up-front investment vs. buying new

- Improved part throughput

- Increased quality

Trust the MWES New Product Development Process

Whether it’s a new product development, a new twist on an existing product, or even just an idea for a game-changing, paradigm-shifting, groundbreaking invention that may only exist in someone’s mind, all have a common element that cannot be compromised for production to move forward and someday succeed: Trust the Process.

Without trust in the process, there can be no collaboration, coordination, team or teamwork. In short, unless you can take it all upon yourself to evoke change, your idea stays just that: an idea.

For the moment, please consider placing your trust in Midwest Engineered Systems and our New Product Development (NPD) process.

New Product Development Workflow

- EVALUATION – Evaluate and question the current operation or process assumptions. This is the beginning of the product process plan.

- REQUIREMENTS – Production and quality requirements are determined and identified. The risk is determined and a risk threshold is established.

- RESEARCH – Areas of risk beyond the threshold are identified. Research and brainstorm process methods. The outcome should result in 2-3 testing options.

- TESTING – Process simulation testing is conducted on the chosen concept to ensure the desired results are met.

- ANALYSIS – After testing is completed, report the data to analyze the production and quality capability.

- RESULTS – The final report is an evaluation of the test performance results. This helps to determine whether to proceed to design & build or retest another concept.

This is where the trust begins. By keeping your budding project here – all under a single roof, all handled by a single, hand-picked team of specialists (not a series of here today/gone tomorrow subcontractors), and without being shipped from one location to another for each stage of development – you can trust MWES to keep your project secure, hidden from any competitor’s eyes, and bound by our mutual non-disclosure agreements (NDA’s). It’s what makes MWES truly unique.

Trust MWES to be a partner in your pursuit of automation from the onset. We’ll utilize our depth of knowledge on facility-wide automation projects to analyze the current production system to build the best automation solution for not just a single line or operation but one that benefits the entire plant.

At Midwest Engineered Systems, with our decades of experience developing automation systems for entire production facilities, it’s common to see opportunities in multi-line plants. Consolidation of operations can bring about step-changes in both throughput and efficiency – if you know what to look for. Our whole plant analysis process involves understanding not just the separate manufacturing operations but how these activities and the components themselves overlap to find where synergies can be found.

It starts with an on-premises walk-through of your facilities where our engineers can see the current processes in operation. This level of detail is needed to understand the nuances of each step that can be easily left out of RFQs or operational summaries.

Bringing together this and other information such as system drawings and timing charts, operator work instructions, and expected production volume, we can then build an accurate representation of how the entire facility could and should operate. From here, the MWES team will develop a whole-system solution that reduces cost and waste while increasing throughput.

In the case of New Product Development, it is entirely possible that your firm may not have the ability to institute an end-to-end automation system all at one time from the start. Trust MWES, and our highly-experienced team, to divide down your whole-system solution into more manageable stages – ones that can be instituted over time. This staged approach can help mitigate downtime, spread capital expenditure budgeting over time, and produce efficiency wins that start building trust to the fullest from day one.

Trust. With over three decades of delivering Innovation Through Automation, the MWES team has delivered trust to partners worldwide with over 4,000 automation solutions – all from under one roof.

Contact us today to learn more about our process development and how we can improve your manufacturing operations.

Building the future of manufacturing, together

How we can help your business with

The MWES Process

Our Process

With each automation project, Midwest Engineered Systems implements a project management process that walks through the steps for successful equipment integration.

Process Development

Our approach to automation process development is to first evaluate the firm’s current production operation and understand the company’s process needs.

Proof of Principle Testing

We offer the ability to experience the performance of an automation system with real parts and production conditions before significant investment in a production automation system is made.

Consolidating Multi-Line Production

We can utilize our depth of knowledge on facility-wide automation projects to analyze the current production system to build the best automation solution.

Engineering for Manufacturability

We can help reduce the costs associated with automation by analyzing and suggesting product and process modifications.

Why work with us

A trusted partner in manufacturing

120+

Team Members

4,000+

Systems Built

100k+

Sq. Ft. Facility

12+

Years RIA Robot Experts

The Future of Manufacturing