INNOVATION THROUGH AUTOMATION

Easy-Arc TC300 Weld Cart

- Home

- Industrial Automation Capabilities

- Robotic Welding Systems

- Easy-Arc TC300 Weld Cart

Interactive 3D/AR View

View this page on your phone and see the weld cart in AR.

Easy-Arc Partners

EASY-aRC Welding Products

Why a Cobot Weld Cart?

The MWES Easy-Arc TC300 Weld Cart is an affordable portable welding robot on wheels. The cart utilizes an ABB collaborative robot (Cobot) which is an industrial robot arm designed for operator safety, ease of use and programmability. The Cobot design and operating speeds allow for use in areas with minimal safety guarding which would be prohibitive to more conventional industrial robots.

The operator can load and unload from a single station shared with the robot envelope. This allows the worker to address high-mix, low-volume operating scenarios in a small footprint of 40 x 56 inches.

Easy-Arc Cart

- Powder-coated steel frame

- Integrated spool holder

- Swing arm for pendant

- Integrated robot, controller and welder within the cart

- Integrated Bluco Modular Table Top

- Casters w/ wheel locks for easy movement

- Expandable controller for additional options and accessories

- Single 480v 3-phase power drop required

- 1-year warranty included

ABB GoFa™ CRB 15000 Cobot

- Superior power and force limiting performance through integrated torque sensors

- Safe robot design – rounded geometry, no pinch/trap points

- Safety certified Category 3, PL d

- TCP speed of up to 2.2 m/s – GoFa is faster than other cobots in its class

- 950mm reach – 12% longer than comparable 5kg cobots

- Powered by OmniCore with best-in-class motion control

Fronius TPS 320i Standard Welding Package

- 320A Push System water cooled welding package

- Innovative touch interface display

- Easily adapted to individual welding requirements

- Standard Weld Package included

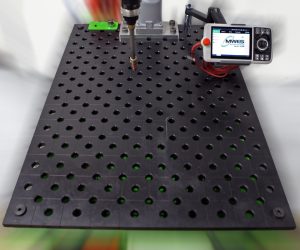

Bluco Modular Tabletop

- 1000mm x 1400mm workspace

- Bluco modular solutions allow you to fixture with the repeatable precision the robot requires

- +/-0.005 inch repeatable accuracy achievable when modular solutions are combined with robotic welding systems

MWES Easy-Arc Software

- Expandable controller

- An intuitive user interface to teach the robot new parts and run production

Additional Options

| Easy Start – On-Site Support | MWES Automation Technician comes to the Customer’s site for either setup, training or programming support. |

| Aluminum Push/Pull Weld Upgrade | The Push/Pull weld package upgrade for the Fronius welder for aluminum welding. |

| Automatic Torch Cleaner | The automatic torch cleaner is activated via the programming pendant. |

| Area Safety Scanner | The safety scanner option allows an operator to work within closer proximity to the cobot. |

| Arc Flash Curtain | The arc flash curtain option is a portable flash curtain that mounts on the cobot cart’s table top. |

| Fume Eliminator/Extractor | A portable source capture system can be added to eliminate welding fumes. |

| Single & 2-axis Positioners | A 1-2 axis positioner for automating more complex welds. |

| Heavy Weld Package | The heavy weld software package adds thru-arc tracking and tactile sensing. |

| Higher Amperage Welder | The 320A MIG weld package can be upgraded to 400 or 500 Amp packages. |

| Long Reach Cobot Models | The cobot can be upgraded to a 10kg payload capacity with a 1520mm reach arm for a larger work envelope. |

| TIG Weld System | Available with or without cold wire feed instead of MIG Weld equipment. |

| Dual Station Configuration | An additional Bluco modular table can be mounted to make a 2-station system. |

| Dual Wire Feeder | Allows for two different welding operations to be performed without costly change outs. |