The food packaging industry is one of the world’s most important and challenging sectors, as it involves preserving, protecting and transporting food to billions of people every day. However, it also faces many issues, such as increasing demand, labor shortages, food safety issues, rising costs, environmental impact and evolving consumer preferences. To overcome these issues, the food packaging and handling industry is increasingly adopting robots to automate and optimize various production processes along the food packaging chain, from sorting to sealing.

Where Robotic Automation Can Improve Food Packaging Production

Robotics Increases Efficiency and Productivity

One of the most significant benefits of robotic automation in food packaging is the increased efficiency and productivity it brings. Traditional manual packaging processes are time-consuming and prone to human error. With the integration of robots, companies can achieve higher output levels in less time. Robots can work tirelessly around the clock, ensuring a consistent and efficient packaging process. This increased productivity translates to reduced operational costs and higher profit margins for businesses.

Robotics Enhances Accuracy and Consistency

Accuracy and consistency are crucial in food packaging to maintain product quality and safety standards. Robotic automation eliminates the variability associated with human labor, ensuring that each package is sealed, labeled, and filled to precise specifications. This level of consistency not only enhances the overall quality of the packaged products but also reduces the risk of contamination and spoilage. As a result, consumers can trust that the products they purchase are safe and of high quality.

Flexibility and Adaptability are a Reality with Robotic Automation

The food packaging industry often deals with a wide variety of products, each with unique packaging requirements. Robotic automation offers the flexibility to adapt to different packaging needs quickly and efficiently. Modern robots are equipped with advanced sensors and artificial intelligence capabilities, allowing them to handle various shapes, sizes, and types of packaging materials. This adaptability enables companies to respond swiftly to changing market demands and customize packaging solutions for different products.

Robotics Automation Improves Workplace Safety

Robotic automation also plays a crucial role in enhancing workplace safety in the food packaging industry. Packaging processes can involve repetitive tasks, heavy lifting, and exposure to hazardous materials. By deploying robots to handle these tasks, companies can significantly reduce the risk of workplace injuries and accidents. This protects employees’ well-being and minimizes the potential for costly downtime and liability claims.

Robotics Bring About Cost Savings and a Return on Investment

While the initial investment in robotic automation may seem substantial, the long-term cost savings and return on investment (ROI) are well worth it. By streamlining packaging processes, reducing labor costs, and minimizing waste, companies can achieve substantial savings over time. Additionally, the increased efficiency and productivity lead to higher output and revenue. As a result, businesses can quickly recoup their investment and continue to benefit from the advantages of robotic automation.

Robotics Are Sustainability and Environmental Impact

In today’s environmentally conscious world, sustainability is a key consideration for many industries, including food packaging. Robotic automation can contribute to sustainability efforts by reducing material waste and energy consumption. Robots can precisely measure and dispense packaging materials, minimizing excess use and reducing the overall environmental footprint. Additionally, the efficiency gained through automation can lead to lower energy usage, further supporting sustainability initiatives.

What Experience Does MWES Have in the Food Industry?

Robotic Case Packing and Sealing

Consistency must be maintained when packing cases so that each case is packed the same way every time. Robotics provide that solution through vision systems and sensors to ensure that cases contain the correct number of units. Additionally, automated case sealing finalizes the process cleanly and efficiently.

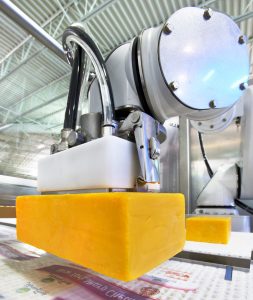

Automated Food Wrapping and Handling

Food wrapping and handling requires high levels of speed, accuracy, hygiene and flexibility to adapt to different types and sizes of containers and products. Hygienic, food-safe robots can help food packagers achieve these goals by handling tasks such as picking, placing, filling and sealing food products.

Automated Food Labeling and Traceability

This process is crucial for providing consumers with accurate and transparent information and ensuring food traceability and recall. Robots can help food packagers improve labeling and tracking by performing tasks such as printing, applying, scanning labels, and collecting and analyzing data.

MWES Is Here to Automate Your Process

Robotic automation is undeniably transforming the food packaging industry, offering numerous benefits such as increased efficiency, enhanced accuracy, food hygienic equipment, improved workplace safety, cost savings, and sustainability. As technology continues to advance, we can expect even greater innovations and improvements in robotic automation, further revolutionizing the way food products are packaged and delivered to consumers.

Embracing robotic automation is not just a trend but a strategic move for companies looking to stay competitive in the fast-paced food packaging industry. By harnessing the power of robots, businesses can achieve higher productivity, ensure product quality, and contribute to a more sustainable future.

Midwest Engineered Systems has decades of experience in designing and integrating hygienic robotic automation systems, including in the food and beverage industry. Contact us today if you are looking to upgrade your existing food packaging operation to a highly efficient, robotically automated production.