Warehouse Management System Interface

- Home

- Warehouse Management System Interface

Managing your warehouse operations with a single interface

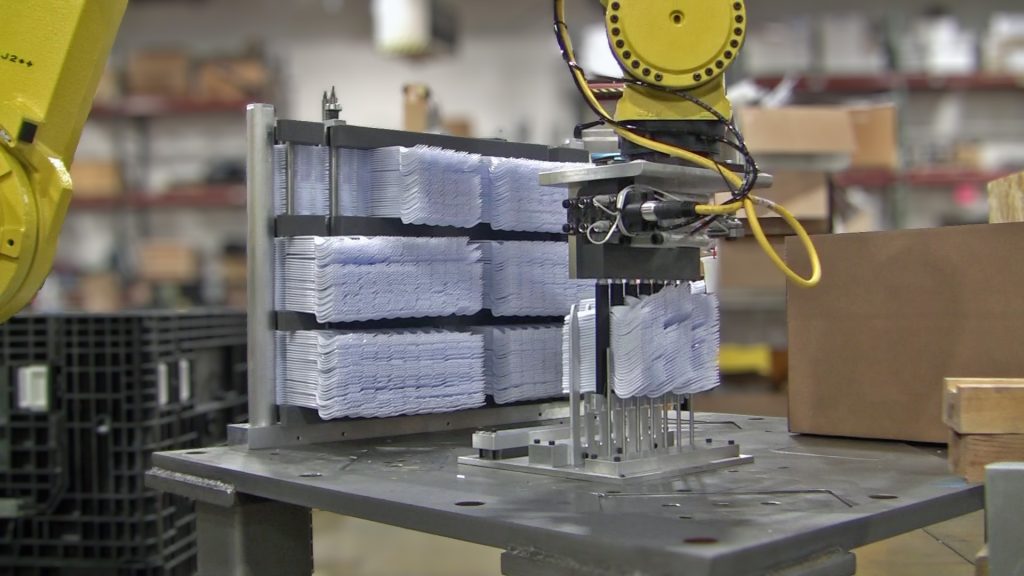

Warehouse Management System (WMS) interfaces are crucial for ensuring seamless communication between various software and hardware components within a warehouse or other logistics environment. The interface of a WMS can provide real-time visibility into inventory levels, enhance order accuracy, and streamline operations from receiving to shipping. This interconnected network helps optimize warehouse efficiency, reduce errors and improve overall productivity and throughput when coordinating human labor, robots, AS/RS systems, AGVs/AMRs, conveyance and more.

- Inventory Management – WMS keeps precise track of inventory levels, reducing the risk of overstocking or stockouts. Coupled with robotic pickers, inventory management becomes faster and more accurate.

- Order Fulfillment – Robotic systems and WMS work together to streamline order picking and packing, ensuring swift and accurate fulfillment of customer orders.

- Real-time Data and Analytics – By integrating with robotics, WMS provides real-time insights into warehouse operations, helping identify bottlenecks and areas for improvement.

- Automation Coordination – WMS orchestrates the movements of various robotic systems, ensuring they work together efficiently, from AGVs to industrial robots.

- Space Optimization – WMS can analyze warehouse space and direct robots to store items in optimal locations, maximizing storage capacity.

- Labor Management – With WMS, managers can effectively deploy human labor where it’s needed most, while robots handle repetitive and hazardous tasks.

WMS seamlessly bridges human workers, robots and operations, creating a harmonized workflow. This integration not only boosts productivity but also enhances accuracy and safety in warehouse operations.

Building the future of manufacturing, together

The Future of Manufacturing