Pallet Quality Inspection

- Home

- Pallet Quality Inspection

Keep your line moving forward by keeping the bad pallets out of it

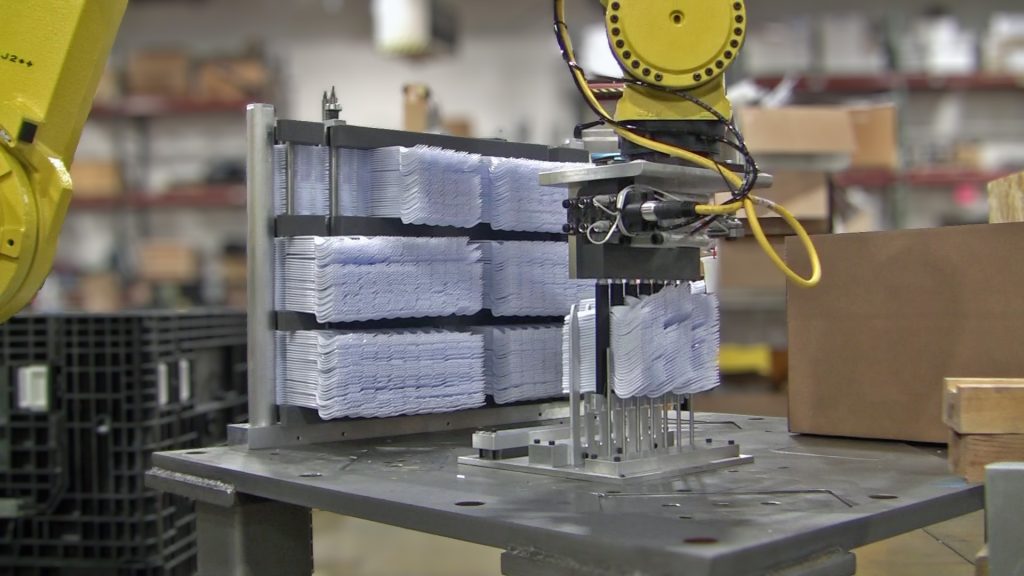

Pallets with broken boards or other defects can potentially bring a production line to a halt if one were to get stuck during conveyance or when being handled by a robot. Work stoppages like that may seem like a minor inconvenience but it can be costly if it becomes a regular occurrence. Inspecting pallets manually requires workers to visually analyze hundreds even thousands of pallets a day which can be overwhelming. Automating the pallet acceptance and rejection process is something we can help you with!

MWES integrates automated pallet quality inspection, rejection and sorting equipment into our automation solutions. The high-speed inspection system inspects incoming empty pallets to ensure the pallet quality by detecting defects that may otherwise cause problems with pallet conveyance, palletizing systems, AS/RS systems or pallet manipulation equipment. This automated solution reduces the responsibilities of the operators on a production line and enables them to focus on other more important areas. The pallet inspection can be used for both wooden and plastic pallets and is being applied to nearly all pallet configurations, which will help prevent load imbalance, production stoppages and potential material loss.

The pallet quality inspection system can handle most types of common pallets, such as GMA, CHEP, PECO, Euro-style and more. The inspection system takes seconds to scans all sides of a pallet looking for protruding nails, cracks in boards and blocks, missing, broken or dislocated boards or blocks, blocked tunnels, logo detection and verification (QR codes, etc.), paper and plastic residue and sorting based on appearance all in real-time. As the system inspects the pallets, the operator will receive real-time data based on set criteria that dictate if a pallet passes or fails and whether it should be taken out of the production line or logistics flow.

What does the automated pallet inspection look for

- Length and width of the pallet

- Length and width of individual boards

- Protruding material – nails, staples, etc.

- Cracked boards and blocks

- Contamination – mold, waste, etc.

- Skewness and planarity

- Discoloration and foreign material

- Plastic wrap residue

- Analysis of tunnels (width and height)

- No material blocking the tunnels

- Missing pallet components

- Pallet orientation

- Analysis of deck and cross boards

This solution is ideal in most industries such as logistics, warehousing, food handling and healthcare to name a few. Good pallet quality improves warehouse efficiency and throughput while preventing work stoppages and damaged materials.

IVISYS PALLETAI

The IVISYS PALLETAI inspects the pallet to secure the pallet quality by detecting defects that not are beneficial for your production or logistics chain. Learn more at ivisys.com

Building the future of manufacturing, together

The Future of Manufacturing