Seam Welding Automation

- Home

- Industrial Automation Capabilities

- Robotic Welding Systems

- Seam Welding Automation

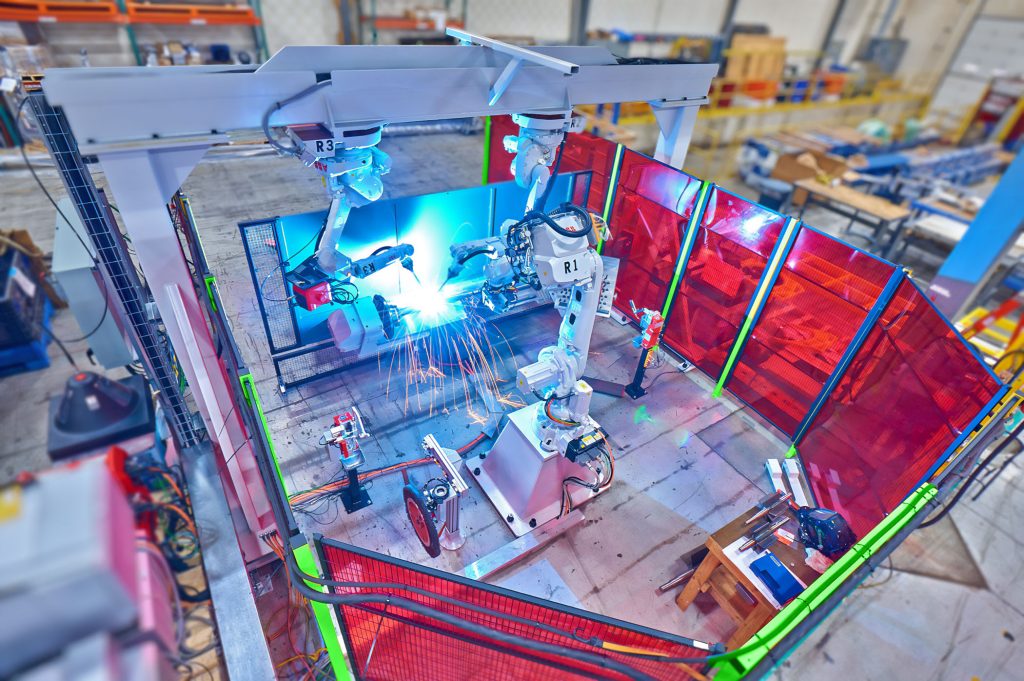

Enhance your Seam Welding Process with Robotics

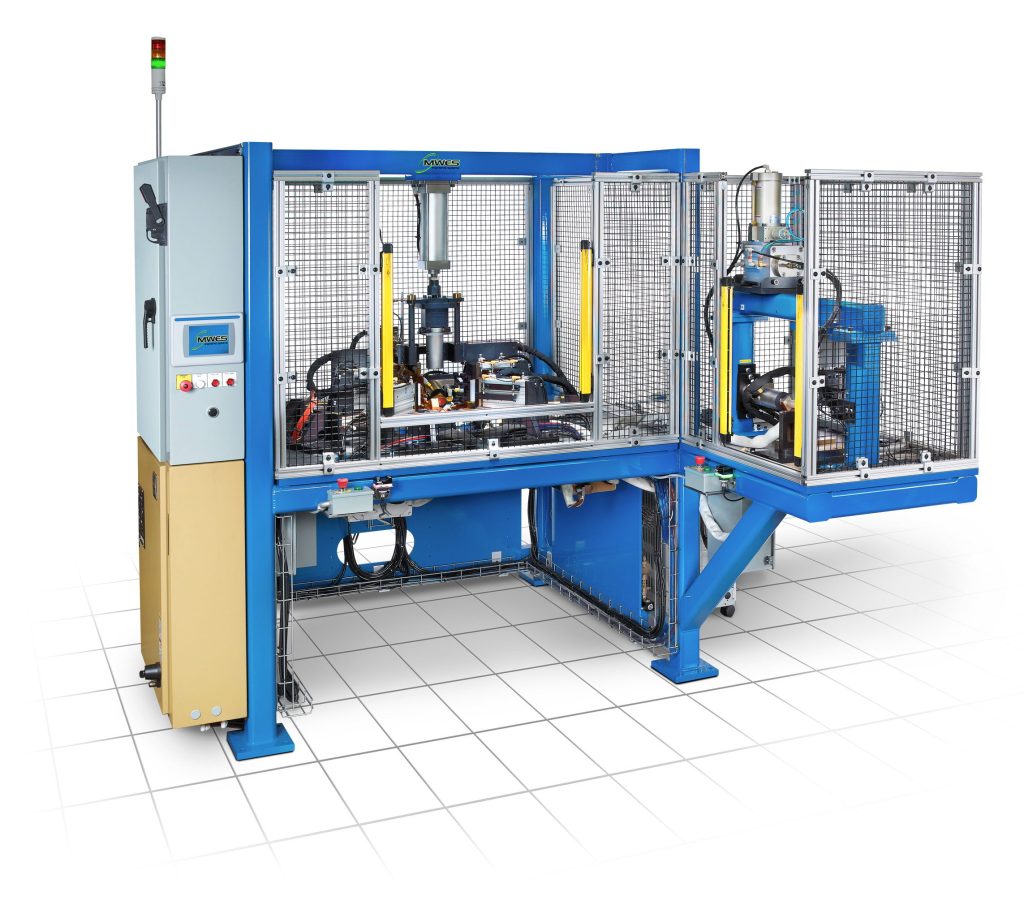

The seam welding process bonds two metals together by making a series of overlapping spot welds created from two rotating roller electrodes. Automating seam welding with robotics is easily accomplished via a custom-designed robot seam welding end-effector or a purpose-built seam welding machine that a robot tends.

Additionally, robotically automating a seam welding process will drastically improve the quality and consistency of the welding bond as it creates a clean, clearly defined weld. Seam welding creates a strong enough bond in the workpiece that makes it fluid and even gas-tight making it ideal for storage vessels and piping. Lastly, gases and thus fumes are not emitted during the welding process, making it a much cleaner and safer process for the workers and environment.

Applications of Seam Welding

Seam welding has many applications in a variety of industries and is compatible with stainless steel, nickel and magnesium alloy metals. Since seam welding produces clean gas and fluid-tight welds, this process is ideal for the construction of metal barrels and storage vessels, as well as fluid and gas piping and valve assemblies. Additionally, seam welding works great with exhaust systems for automotive, industrial equipment, aerospace applications and more.

MWES has the experience and know-how to provide our customers with the proper welding process for the correct welding application. Integrating these processes with robotic welding automation will keep your manufacturing process competitive for many years to come. Contact us today and see if your welding operation would benefit from robotic automation.

Building the future of manufacturing, together

World-class Automation