Automated Splicing Equipment

- Home

- Industrial Automation Capabilities

- Web Handling & Converting

- Automated Splicing Equipment

Enhance Your Splicing Equipment with Automation

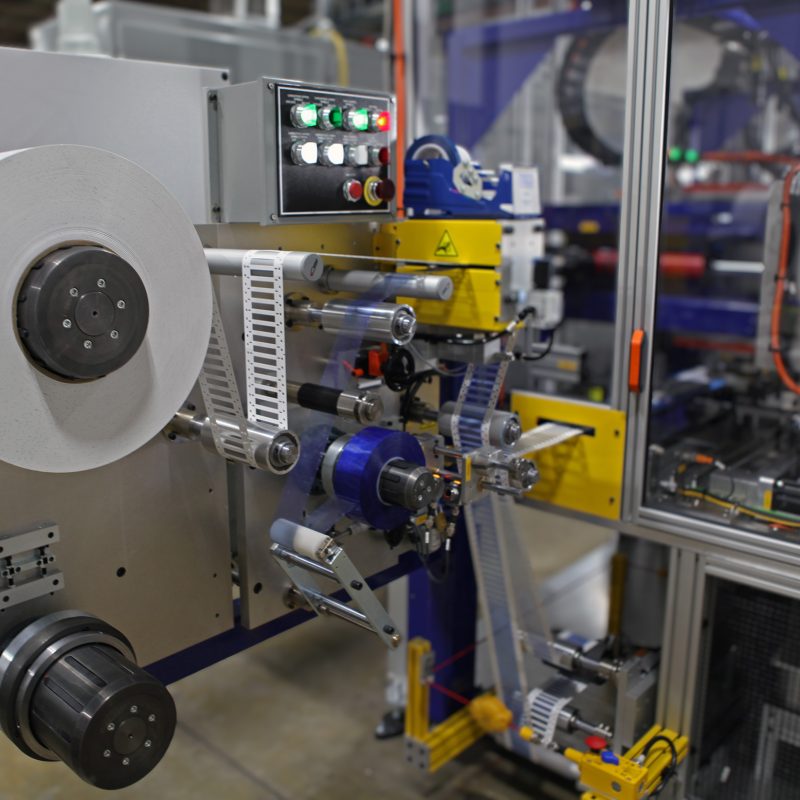

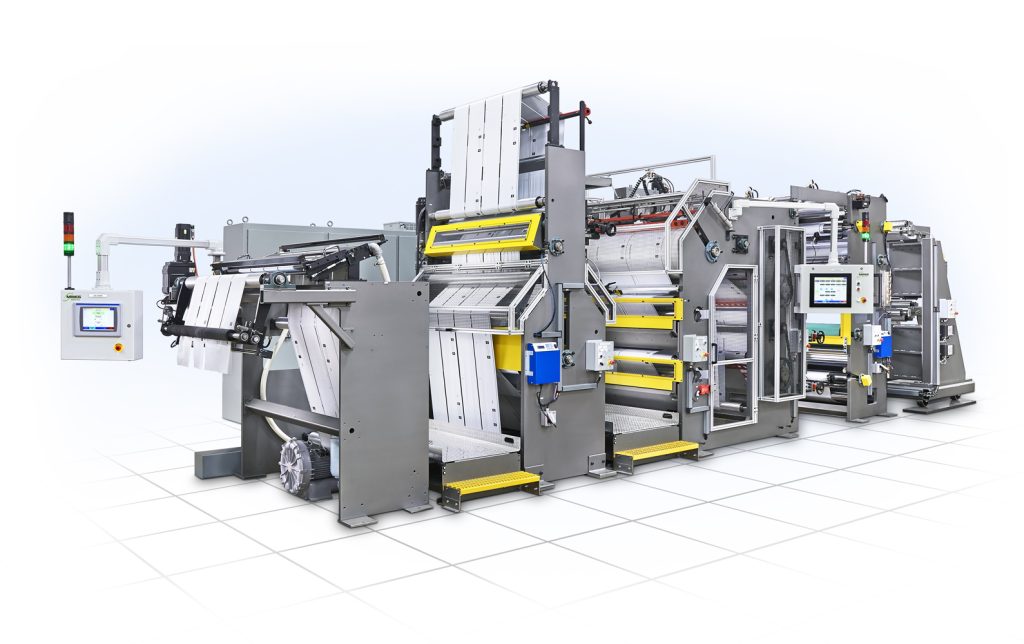

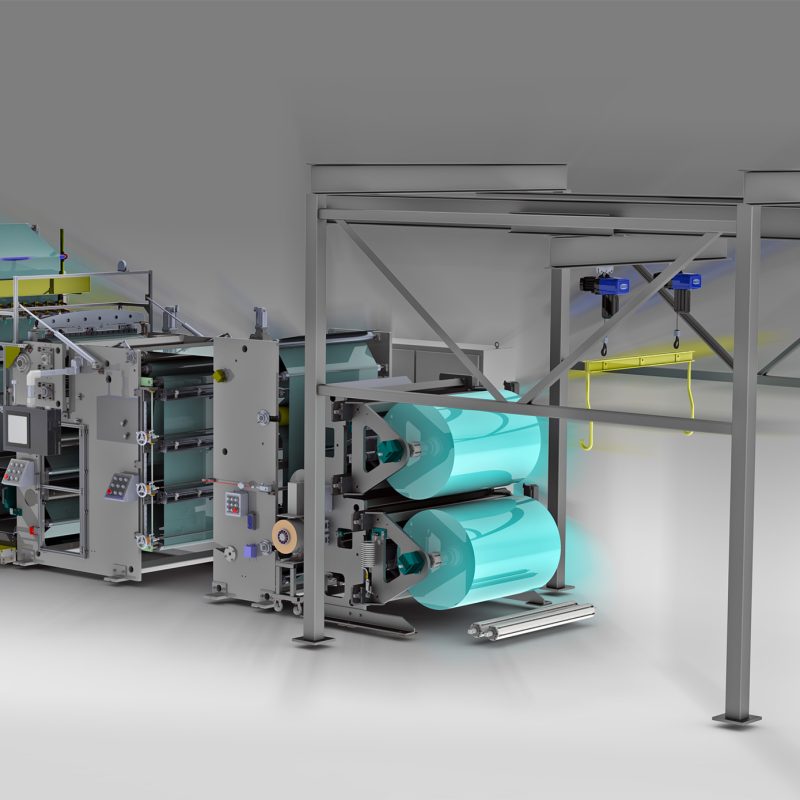

Midwest Engineered System designs and manufactures automated splicing equipment for web handling systems with various formats and capabilities. Automated splicing equipment plays a crucial role in web handling systems and is used in various manufacturing and printing processes. These systems handle the continuous feed of materials from rolls through a machine for processing. Modern splicers have features like automatic press stops, web-up carriages, and web acceleration to ensure a smooth transition between rolls. These systems can also include monitoring and motorized side-lay for precise alignment.

Automated splicing is essential for maintaining productivity as it allows for joining the end of an expiring web roll to the beginning of a new roll without stopping the machine. Additionally, splicing equipment features include single or dual-direction splicing, zero-speed, flying and synchronized splicing, and rewind carriage-style splicing with layon roll to remove trapped air.

Automated splicers enable non-stop operation of the production line. When one roll finishes, the equipment seamlessly joins the next roll, keeping the line running without manual intervention. The two types of splicing are butt splicing which brings two web ends together without any overlap and overlap splicing which allows for a small area of overlap, secured with adhesive.

Our design and build solutions can include customized robots, cable solutions, vision systems, safety enclosures, process monitoring, control systems, and other technical equipment, to help you and your organization to improve your manufacturing process. Splicing equipment is a testament to the advancements in manufacturing automation, offering reliable, efficient and continuous web handling to meet the demands of modern production environments. Our equipment can be tailored to specific production needs, handling a wide range of materials and web widths.

MWES has extensive experience analyzing web production processes uniquely positions us for web handling applications on new and existing equipment. Contact us today to learn more about how we can help increase your production throughput.

Building the future of manufacturing, together

World-class Automation