Blog & News

Check out the latest from MWES

Categories

How Lights-Out Manufacturing is the Future of Manufacturing

Lights-out manufacturing is not a fantasy, but a reality that is becoming more common in the manufacturing sector. It requires the support of various technologies, such as machine learning, cloud data, machine vision and robotics. These technologies allow machines to communicate with each other, monitor the production process and perform

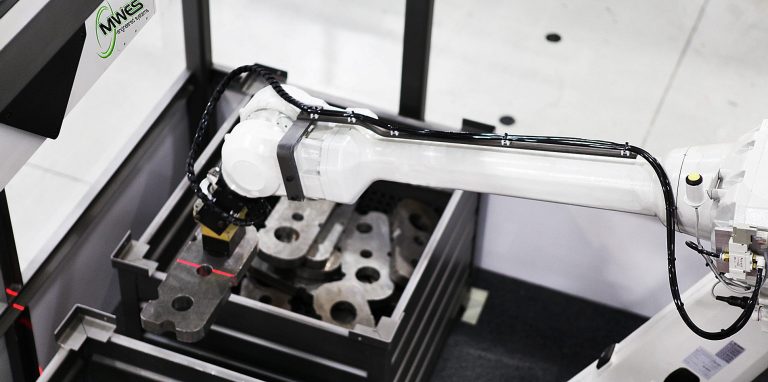

Factory Automation with Robotic Production Systems

Midwest Engineered Systems has spent decades improving our customers’ factory automation processes with robotic automation systems. By moving to robotic automation, those firms benefited from having a sizeable return on investment (ROI) and greatly improved throughput in their factory operations, all the while not being burdened by the labor shortages

Tips for Maintaining Your Industrial Robots

Just like all machines industrial robots require regular maintenance to keep running effectively and safely. The motors, electrical components, end-effectors and joints are vulnerable parts of a robot that can fail or lose effectiveness if not properly inspected and maintained. Underperforming robotic systems due to negligent maintenance can negatively affect

The Demographic Cliff: How AI and Automation are Filling the Gap

Baby boomers are reaching retirement age in large numbers, which means a significant portion of the workforce is leaving their jobs. This has led to concerns about a potential labor shortage, especially in industries that traditionally rely on skilled and experienced older workers, such as healthcare, manufacturing and skilled trades.

MWES is Ready for Industry 4.0

Industry 4.0 is used to describe the Fourth Industrial Revolution, which is characterized by the integration of digital technologies, such as artificial intelligence, cloud computing, big data, and the Internet of Things (IoT), into the manufacturing processes. One of the main benefits of the introduction of Industry 4.0 into robotics

Thank You to Everyone who Came Out to WIMTS

We would like to thank everyone who stopped by our booth last week at the Wisconsin Manufacturing & Technology Show (WIMTS) at the Wisconsin State Fair Park. At our booth, we showcased the Easy-Arc Welding Cobot Cart which was a big hit with the students and attendees alike. In addition

FABTECH Recap & Upcoming Trade Shows in October

THANK YOU to everyone who stopped by our booth at FABTECH last week – the show was a huge success! Our staff had a great time talking to everyone and discovering what is important to them in their manufacturing process and the problems they face. At the MWES booth, we

Introducing the MWES Easy-Arc TC300 Weld Cart

Safe, mobile, dependable, repeatable and easy to use. Today Midwest Engineered Systems announces its entry into the robotic weld cart arena with the MWES Easy-Arc Collaborative Robot Weld Cart. This affordable and flexible welding solution is an ideal investment in times when skilled welders are in short supply and onshoring

AS/RS Buffer Systems: Warehousing on a Whole New Level

Warehouse management is a complex and challenging task that requires efficient and reliable solutions. One of the most innovative and effective solutions is the automated storage and retrieval system (AS/RS) buffer system, designed to optimize inventory storage and retrieval, reduce travel time, increase throughput and enhance flexibility.

Join Us at FABTECH 2023 in Chicago

FABTECH is North America’s largest metal forming, fabricating, welding and finishing event of the year! Midwest Engineered Systems Inc. will be exhibiting at this year’s FABTECH expo which runs September 11-14 in Chicago, IL at McCormick Place. At this year’s FABTECH we will be introducing our NEW MWES Easy-Arc TC300