Blog & News

Check out the latest from MWES

Categories

The True Cost of Workplace Injuries and the Solution

Workplace injuries and illnesses are a significant problem for workers and their employers in every sector of the economy. According to the U.S. Bureau of Labor Statistics, over 2.6 million work-related nonfatal injuries occurred in 2021 in the private sector, with manufacturing jobs having the highest rate of workplace injuries

The Return on Your Investment: Manual vs. Robotic Automation

Why would you want to use robotic automation over manual labor? Simply put robotic automation offers many benefits for your business, such as increased productivity, efficiency, quality, safety and throughput. All of these add up to substantial savings over the long term for any business that deals in manufacturing, assembly,

Packaging Automation for Medical Life Sciences

MWES solved an issue for a Nutraceutical firm needing help with pill packing. The customer was using multiple employees to place their product into boxes for shipment, struggling with accuracy, speed, and occasional staffing issues. MWES introduced a complete system that utilized a FANUC collaborative robot capable of erecting boxes at a rate of up to four boxes per minute.

Adding Automation to Your Food Handling Production

Automating a food handling production line is becoming increasingly more important these days. With the ongoing pandemic and labor shortages affecting virtually all businesses big and small, moving from an unreliable manual workforce to robotic automation is essential. A leading food manufacturer came to us intent on enhancing their production line with robotic automation.

Upgrade Your Old Manufacturing Operation with New Automation

Many businesses rely on machines that are decades old, and those machines develop a great deal of wear and tear over time. Maintenance costs and down-time for repairs can be a costly expense and severely hinder production line throughput. An automotive parts manufacturer came to Midwest Engineered Systems afflicted with that very problem.

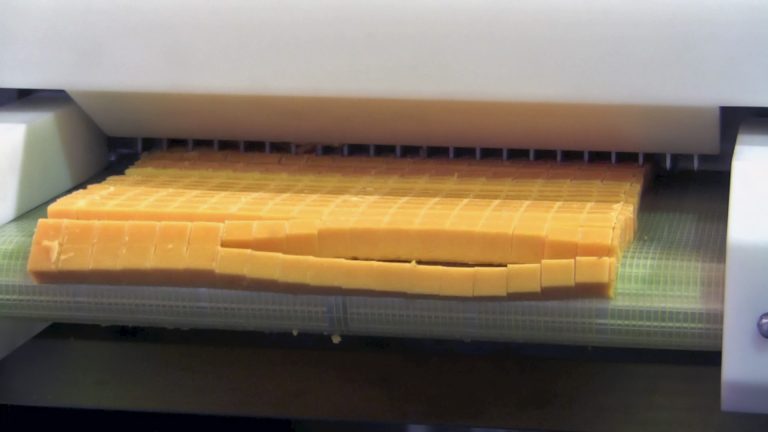

Expand Your Existing Automation with MWES

As your business grows, so will the demands on your manufacturing throughput. However, if the original manufacturer of your existing automation system is no longer in business, you will be forced to look elsewhere to expand your automation throughput. A leading national cheese supplier came to Midwest Engineered Systems with that very problem.

Project Spotlight: Automated Palletizing with Robots

Midwest Engineered Systems built a robotic palletizing system that could move over 80 cases per minute. The robotic integration required no tooling changes to accommodate varying case sizes, or to handle the layer slip sheets. This system also utilizes an automated pallet dispenser, and can produce multiple pallet patterns.

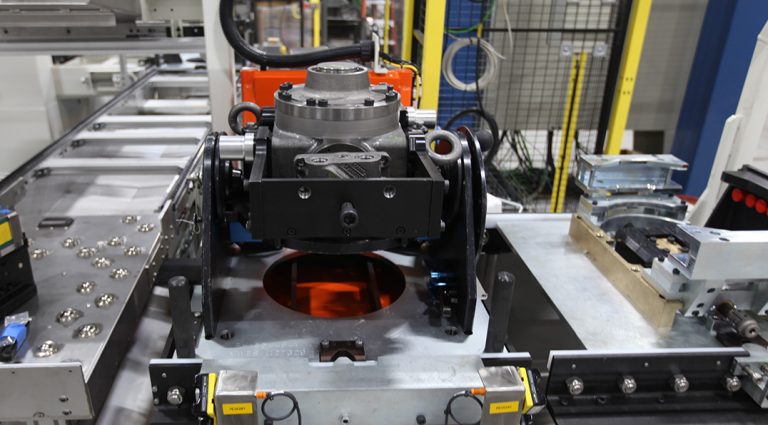

Project Spotlight: Hydraulic Motor Assembly Line

MWES designed a single manual production line for a firm that could manufacture over a dozen different variations of a hydraulic motor. The line utilizes a large number of sub-assembly stations, where workers perform the required tasks based on the specific variant of the motor being assembled.

Project Spotlight: Welding and Milling Bus Bars Robotically

With the current ongoing labor shortage, skilled welders are in short supply leaving many businesses to rely more heavily on robotics to fill that void. Fully automating a 24/7 welding operation is not as complicated or as intimidating as it may sound. What if the production line requires multiple stations or has to handle different metal types?

Project Spotlight: Trigger and Bottle Assembly Line

Midwest Engineered System built a fully automated assembly line that required no manual labor to perform the assembly operation. Robots using a vision system would pick and sort the multiple types of triggers as they travel on a single conveyor. On a separate conveyor, filled bottles would arrive at the bottle assembly station.