Blog & News

Check out the latest from MWES

Categories

Project Spotlight: Welding and Milling Bus Bars Robotically

With the current ongoing labor shortage, skilled welders are in short supply leaving many businesses to rely more heavily on robotics to fill that void. Fully automating a 24/7 welding operation is not as complicated or as intimidating as it may sound. What if the production line requires multiple stations or has to handle different metal types?

Project Spotlight: Trigger and Bottle Assembly Line

Midwest Engineered System built a fully automated assembly line that required no manual labor to perform the assembly operation. Robots using a vision system would pick and sort the multiple types of triggers as they travel on a single conveyor. On a separate conveyor, filled bottles would arrive at the bottle assembly station.

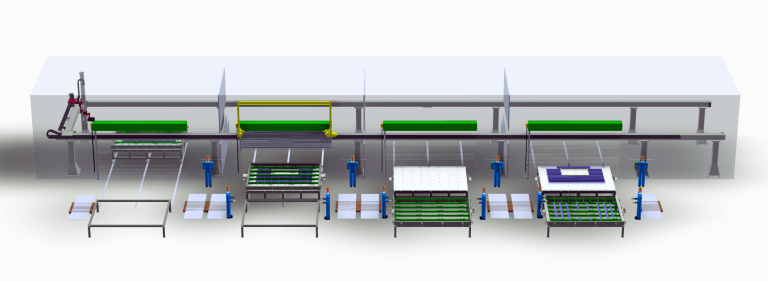

Project Spotlight: Rail Car Assembly

When you’re riding on the subway, most people don’t think about how the car they are riding in was assembled much less the process behind it. MWES built a robotic welding system that would allow a single robot on an overhead gantry to work in tandem with human workers safely.

What’s on our floor: SkyHook extra-large positioners

Automation systems come in a variety of sizes. Some are small enough to process sensitive medical operations. They scale up from there to robotic systems that can process parts the size or weight of a car and beyond.

Project Spotlight: Automated Picture Frame Assembly

Automating high volume production operations is relatively straight forward: design a specialized machine that only produces one part. The rest of the time is spent to make it robust enough to do it at speed and for a long time before service.

What’s on Our Floor: OnRobot Grippers

In the automation world, many times it’s the gripper that packs the most innovation on a system. The grippers are where the automation system actually interacts with the products moving through the cell.

Robotic Palletizer that Handles a Variety of Product Sizes

Many don’t realize that robot arms can be equipped with an EOAT that is capable of cleanly grabbing multiple products at once. Our custom designed robot gripper made this palletizing process a breeze.

Part lead times are growing – Make sure you’re prepared

Economies are opening up and demand for many products and services are surging. It’s predicted that most companies will see massive demand for their products in the near future, if it hasn’t happened already.

How to know if robotic welding is right for your application

Knowing when to automate processes can be a tricky prospect. When looking at replacing a highly skilled, yet difficult to fill human operation like production welding with robotic systems, the question can become even more murky.

What to know about cobots – before you buy one

We’ve put together three important truths about collaborative robots that a manufacturing engineer or manager should understand before taking the plunge on a cobot for their processes.