Blog & News

Check out the latest from MWES

Categories

Celebrating Three Decades of Trustworthy Automation Integration

This month Midwest Engineered Systems is celebrating 30 years in the automation industry. MWES started in 1991 by Scott Woida, and has grown to be a leading provider of automation systems for a large cross-section of industries.

Losing production speed? Consider upgrading legacy systems!

Over the course of their lifetime, production line automation systems begin to lose efficiency. Replacing with a completely new system would definitely improve throughput and would bring the machine production tracking technology up to date.

See our medical vial filling machines in action!

This video from the firm shows our systems at work. Our automation systems are helping the company decrease virus testing times by increasing the production of collection transport systems. At one point in the video, COPAN specifically highlights our second-generation robotic vial filling cells and the 200,000-vial filling per week performance they achieve.

A Checklist for Automation RFQ Information Whitepaper

Putting together an RFQ or even earnestly exploring automation, is a job unto itself. It can be difficult to know what an automation integrator may need to start the process. Providing the right information helps develop a quote package.

Automates part infeed operation with robotic conveyor picking

There’s plenty of machine tending systems on the market, but how do the parts arrive to these systems? Chances are, there’s a large amount of manual labor being used to unload pallets and bins to feed them.

Get Universal Robot programming and integration on-site

MWES offers UR robot system service on-site to get the most out of your robotic arm without wasting months learning how to program them yourself.

Consolidating production processes with automation

Moving toward automating production facilities that have a few or more lines can be an overwhelming prospect. Each line may need upgrades. Judging which should receive more of the budget is a task that may not have a clear cut solution.

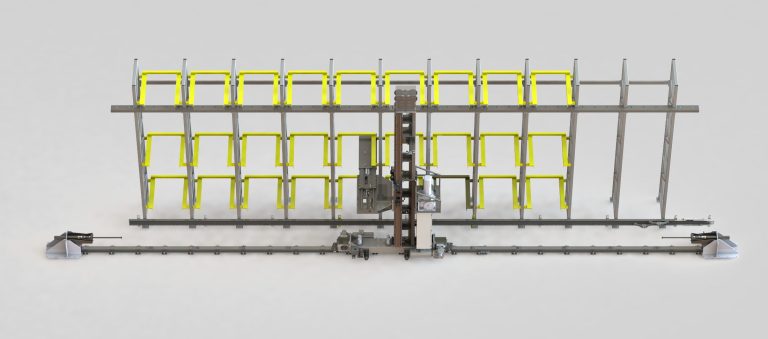

Looking for a step-change in material and tooling workflow management?

Next level production performance and control with our automated storage and retrieval buffer system built expressly for existing manufacturing facilities.

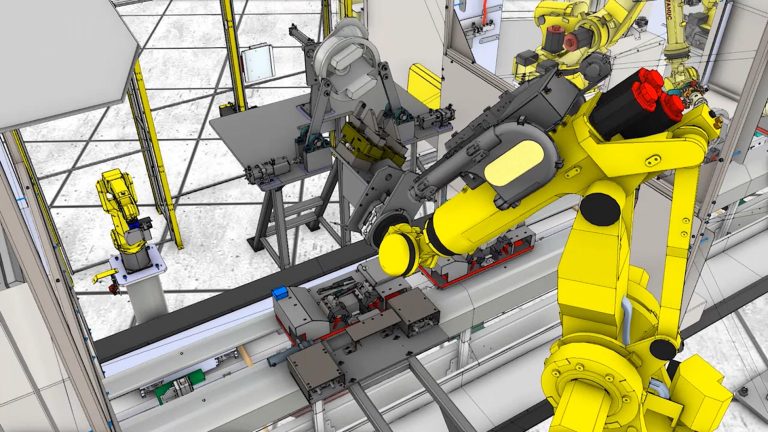

Proving Robots Can Do Heavy Cutting with Precision

An example of proof of concept testing for a previous project. In this video, we’re testing the capabilities of industrial robots to cut a section of heavy pipe. The pipe was a stand-in for the large steel parts the eventual automation system.

Proof of Principle Testing Takes the ROI guesswork out of automation

Looking into automation for a particular production process? Determining if automation is the correct way to go may be a rather murky prospect, especially if there’s no off-the-shelf system to do it. There’s a way to prove out whether automating that process would have the ROI that the firm needs without having to build the entire system.