Standard Case Packing Machine

- Home

- Industrial Automation Capabilities

- Material Handling Automation

- Case Packing Systems

- Standard Case Packing Machine

Standard Turn Key Food-grade Case Packing Solutions Fit for Most Applications

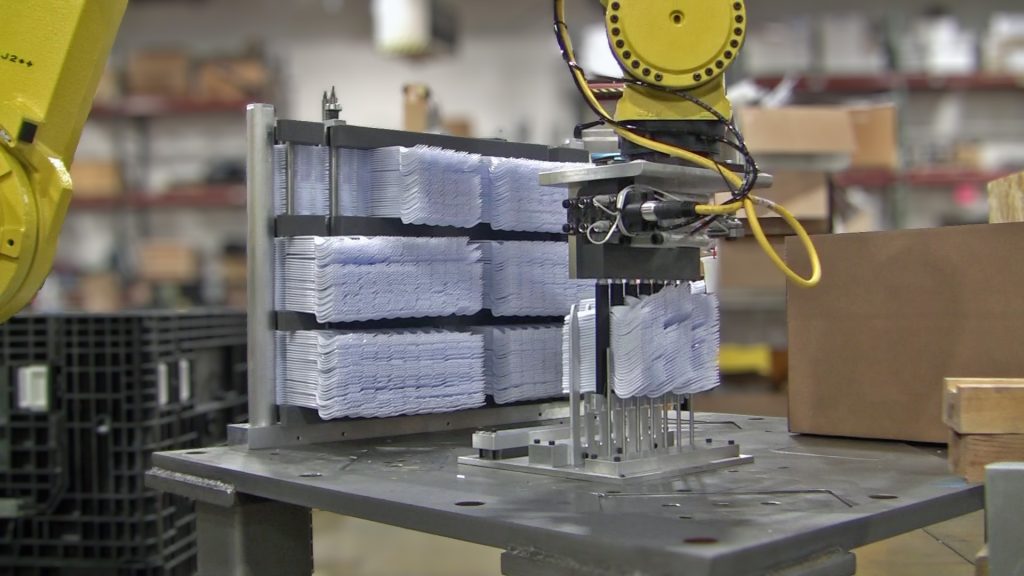

Fitting in a compact footprint, the MWES standard pack-out system is comprised of either two or three pick-place robots encapsulated in a sterile ridged structure. These robots move products between integrated conveyors that are adjustable in width to fit a variety of product sizes and secondary packaging sizes. The pick-place robots meet IP67K or IP69K international standards for water resistance and waterproofing.

The standard machine’s structure also houses all of the control hardware and power routing for the system and is shipped as one complete system. Although there will need to be some routing of conveyor lines from current production systems, all that’s needed in terms of installation is the ability to bolt the system to a properly rated floor, a power drop, airdrop and Ethernet connectivity. This configuration provides a stable and compact system that requires very little time to set up on the production floor.

Increase Throughput and Reduce Worker Burnout

In terms of production speeds, an MWES pack-out system with three pick-place robots can fill boxes at a rate of between 120-160 packages per minute. This performance is roughly equivalent to the speed at which 3-4 dedicated human hand packers could provide while offering more consistent performance and quality. The self-contained system also offers adjustability for a variety of different-sized bags as well as the ability to pack them in precise pack patterns. As a robotic system, it can perform at this pace for all three shifts without rest and could be configured to run in most cold rooms.

From the start, the MWES pack-out system was designed to integrate into existing production lines including tight floor space applications. All aspects of the machine, from robots to control systems, are housed within the system’s frame. The system only requires power and production line connection to operate once the machine is placed in the facility. Sometimes installation can be completed in as little as a day. Its compact footprint also allows for more placement options on the production floor and the potential for recovering valuable floor space.

With quality labor becoming scarce, wages rising and profitability tied so closely to production efficiency, the MWES pack-out system makes sense for firms that are searching to find the most streamlined packaging processes. Adding MWES’ 24/7 service, the combination of equipment and support creates the winning choice for CPG packaging operations.

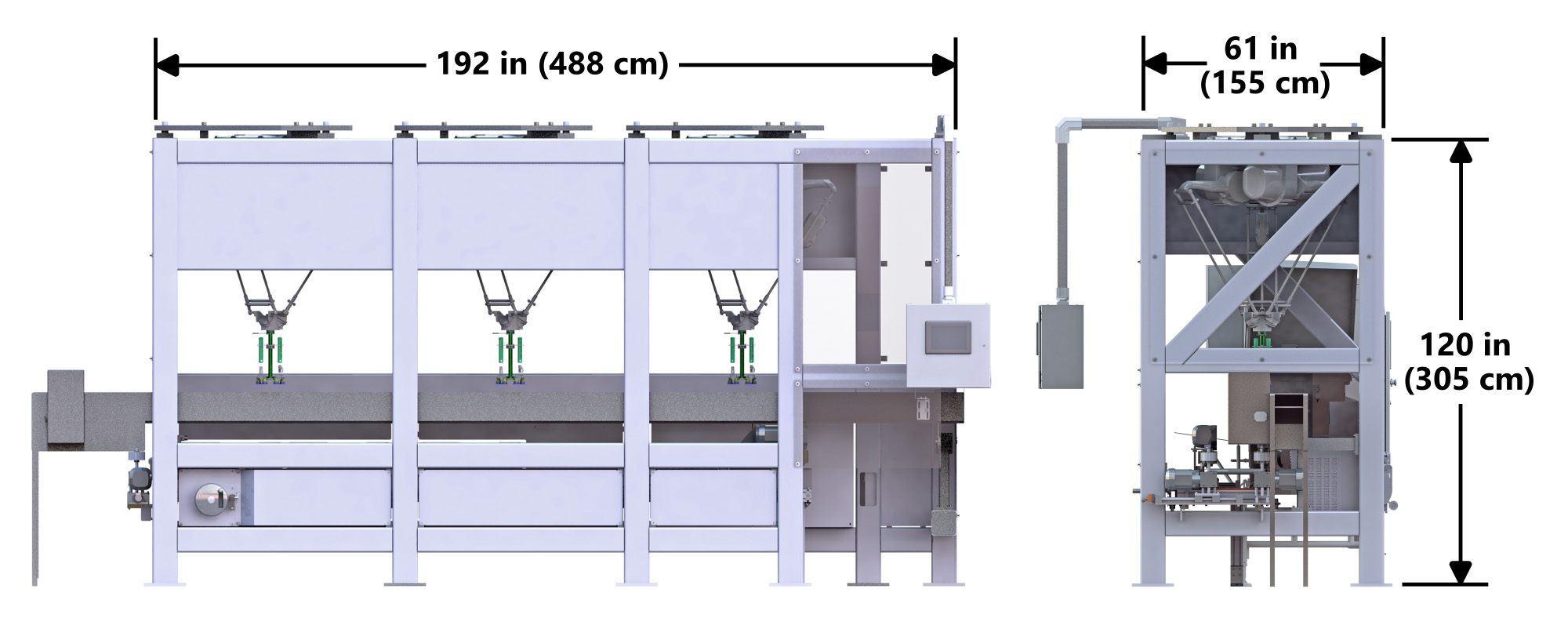

Three-Robot Case Packing Machine

The larger of the two standard systems, MWES offers its food-grade robotic case packer systems in a three robot configuration for applications with greater throughput needs. The three robots combined can provide case packing operations at a pack rate of up to 120 bags per minute and offer all of the features of advanced systems including a trainable machine vision system and easy, menu-driven control that allows operators to update the system to new bagged products without the need for specialized training or certification.

The larger of the two standard systems, MWES offers its food-grade robotic case packer systems in a three robot configuration for applications with greater throughput needs. The three robots combined can provide case packing operations at a pack rate of up to 120 bags per minute and offer all of the features of advanced systems including a trainable machine vision system and easy, menu-driven control that allows operators to update the system to new bagged products without the need for specialized training or certification.

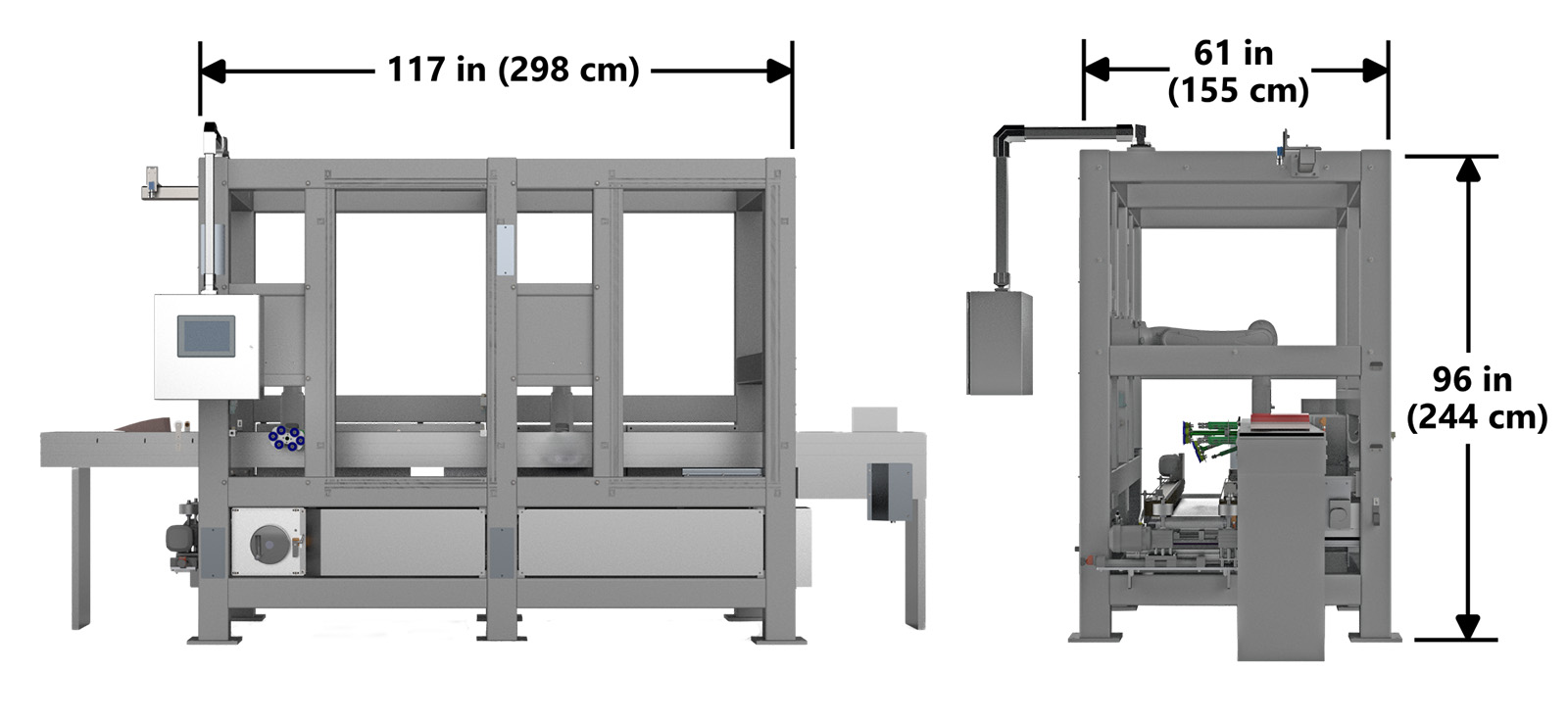

Two-Robot Case Packing Machine

MWES offers its standard food-grade robotic case packer systems in a two robot configuration for applications with a moderate amount of throughput. The two robots combined can pack at a rate of up to 80 bags per minute and offer all of the features of larger systems including a trainable machine vision system and easy, menu-driven control that allows operators to update the system to new bagged product sizes without the need for specialized training or certification.

MWES offers its standard food-grade robotic case packer systems in a two robot configuration for applications with a moderate amount of throughput. The two robots combined can pack at a rate of up to 80 bags per minute and offer all of the features of larger systems including a trainable machine vision system and easy, menu-driven control that allows operators to update the system to new bagged product sizes without the need for specialized training or certification.

Both standard systems’ self-contained design houses everything that the cell needs to operate aside from power, air and Ethernet connections. The essential drop-in system can be positioned with a suitably sized forklift on the production floor. Once utilities are hooked up and conveyors from the customer’s existing manufacturing system are routed, the MWES case packer system can be up and running in as little as a day.

Building the future of manufacturing, together

The Future of Manufacturing