Finishing

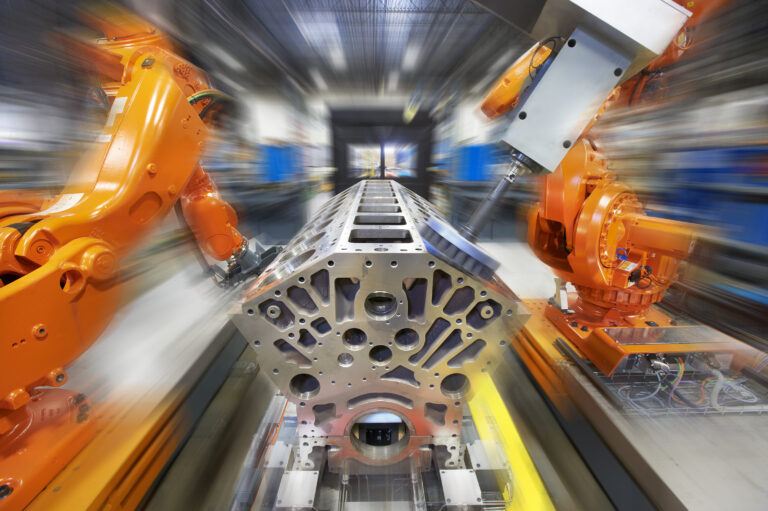

MWES has become adept at automating a variety of foundry finishing processes including casting, cutting, buffing, sealing, grinding, blast cleaning and more. These cleaning and finishing processes are used to remove molding materials, risers, fins, ingates and other excess surface metals. Robotic systems, with their greater degrees of articulation, coupled with advanced programming have also become adept at clearing holes and passageways, as well as removing sand defects in castings.

Employing vision systems, we can provide precise casting location and orientation for robotic machining operations. This vastly reduces the need for custom fixturing for every part or purpose-built machine. Combining the benefits of machine vision’s ability to provide part identification, inspection and measurement, opens up the ability to efficiently handle high-mix, low-volume casting finishing processes in a highly automated manner.

With automated tool-changing options, a large selection of operations is available. They allow users to customize robotic grinding and deburring systems for specific applications and easily extend the utility of installed finishing automation systems. Process tools include burrs, brushes, cut-off wheels, grinding stones, abrasive and flap-style wheels, as well as specially engineered tools. With up to 30 hp available in spindle power, the opportunities for automating finishing or rough machining many operations, are well under control.

MWES offers stock configurations of automated grinding cells. We also develop custom installations that are designed to accommodate functionality needed for specialized processes or scales of operation.