Safety Features of Robotic Automation

- Home

- Industrial Automation Capabilities

- Robotic Automation Systems

- Safety Features of Robotic Automation

Keeping your automation systems safe to operate for your team

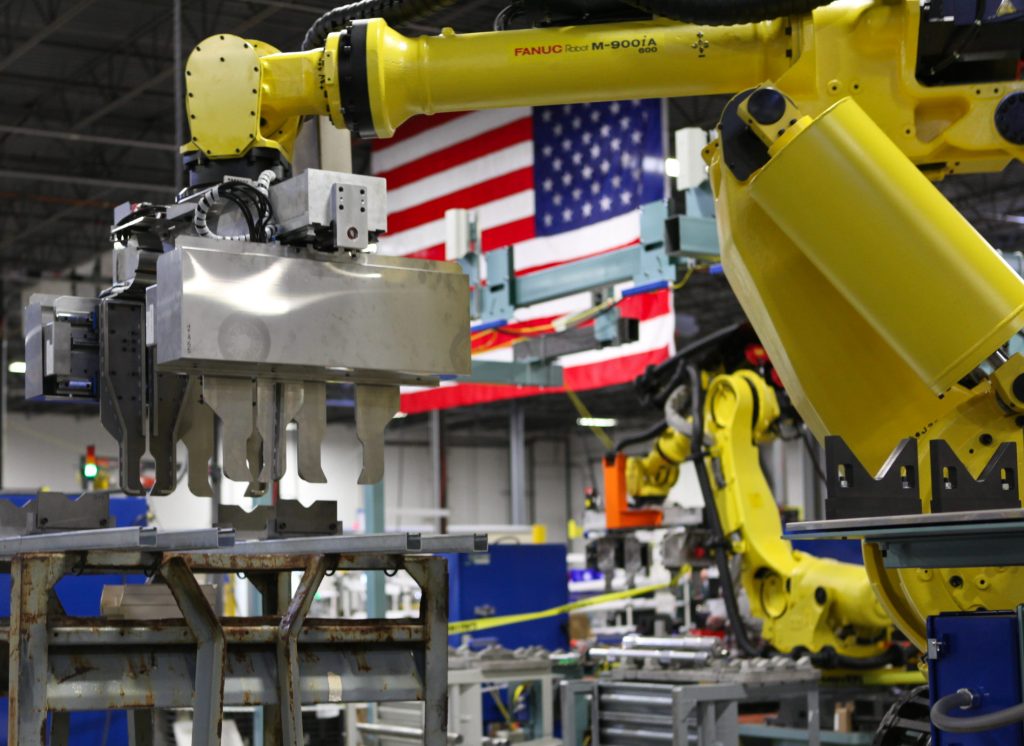

With the rising cost of insurance and staffing shortages, keeping your team safe from the automation systems when in use and your throughput consistent is imperative for staying competitive. MWES knows this all too well and has for decades been integrating safety features with automation systems in every system we integrate.

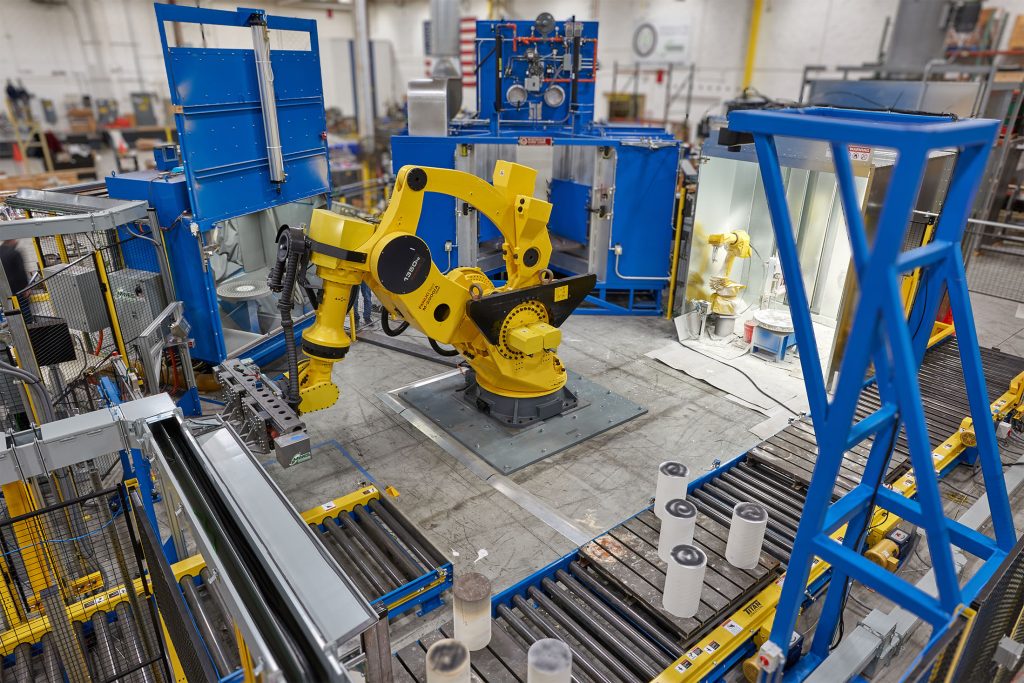

Midwest Engineered Systems employs OSHA-approved passive and active safety equipment in all of our integrations. Passive safety systems are designed to reduce the likelihood or severity of accidents by using physical barriers, sensors, alarms, or light curtains. Active safety systems detect and respond to hazardous situations using feedback loops, control algorithms, or operator intervention.

Passive Safety Systems

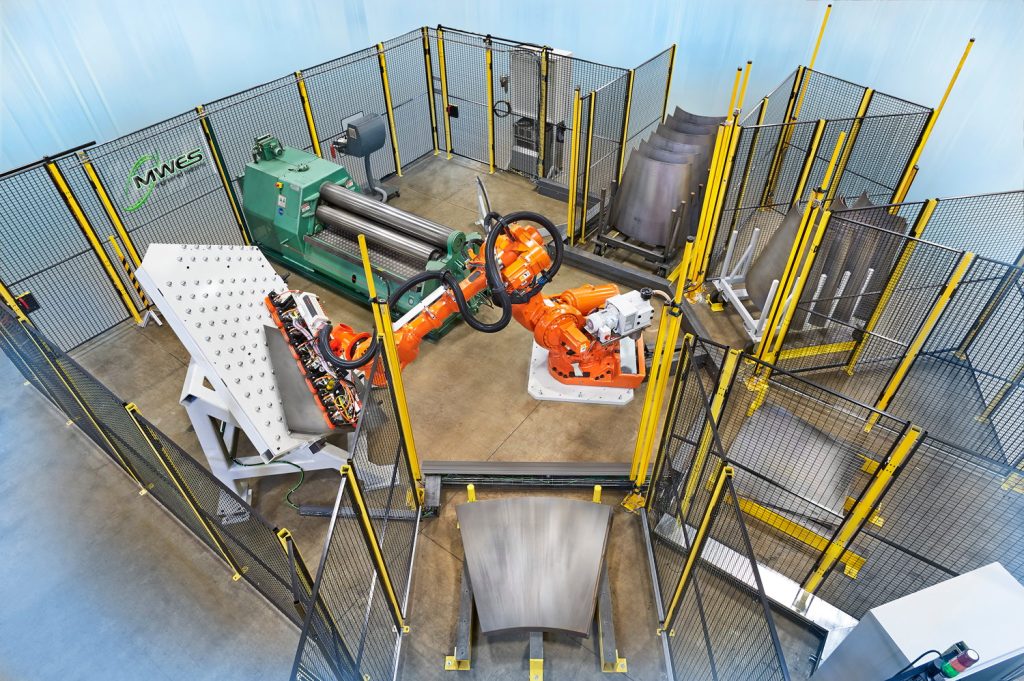

- Fencing or that separates the operators from robots or other machinery

- Interlocks that prevent robots from operating when an operator enters the workspace

- Physical guards that protect the operators from moving parts or machinery

- Sensors on the robots that detect obstacles, collisions or malfunctions

- Light curtains that detect the presence of the operator or foreign objects entering the workspace

- Multiple Emergency Stop buttons placed in accessible locations around the system that allow the operators to stop the automation immediately in case of emergency

Active Safety Systems

The types of active safety systems MWES utilizes:

- Feedback loops that monitor and adjust the performance and behavior of robots

- Control algorithms that ensure the stability and robustness of robots

- Human-in-the-loop systems that require the operator’s confirmation or supervision for certain actions or decisions of the robots

- Human-out-of-the-loop systems that allow the operators to delegate authority or responsibility to robots

- Human-on-the-loop systems that enable the operators to intervene or override the actions or decisions of robots

Robotic safety systems are not only important for protecting your team members from the robots during production but also for protecting the robots from misuse. Automation safety systems require careful design, implementation and regulation. Intelligently designed safety systems are a key component of robotic automation that can help achieve this goal.

Here at Midwest Engineered Systems, safety is at the forefront of the systems we provide our customers. If you would like to know more about the safety systems we employ with our automation systems, please contact us today.

Building the future of manufacturing, together

World-class Automation