Ultrasonic Plastics Welding

- Home

- Industrial Automation Capabilities

- Web Handling & Converting

- Ultrasonic Plastics Welding

Automate welding plastic components together

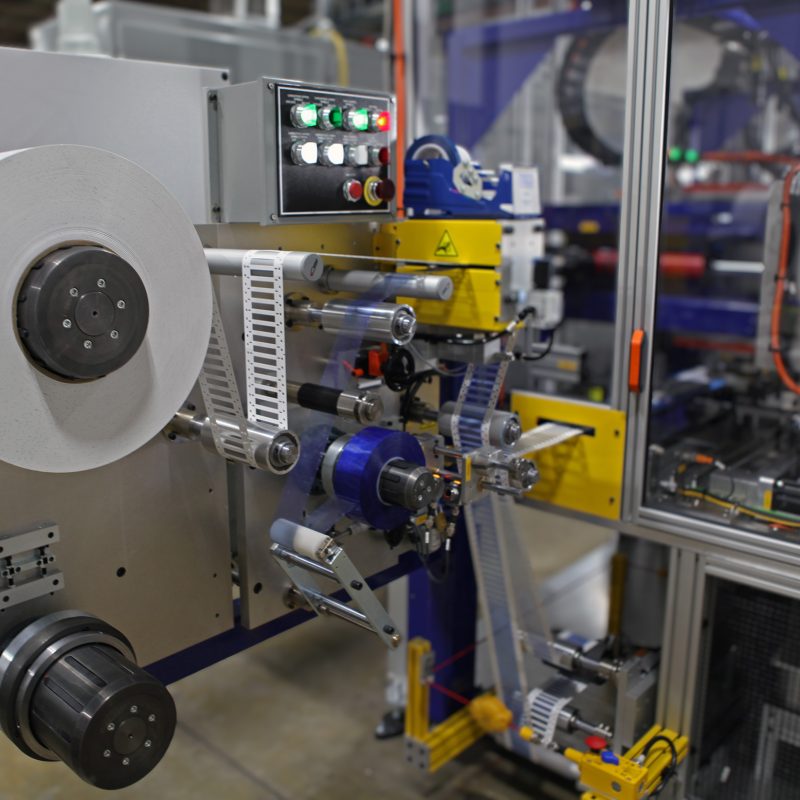

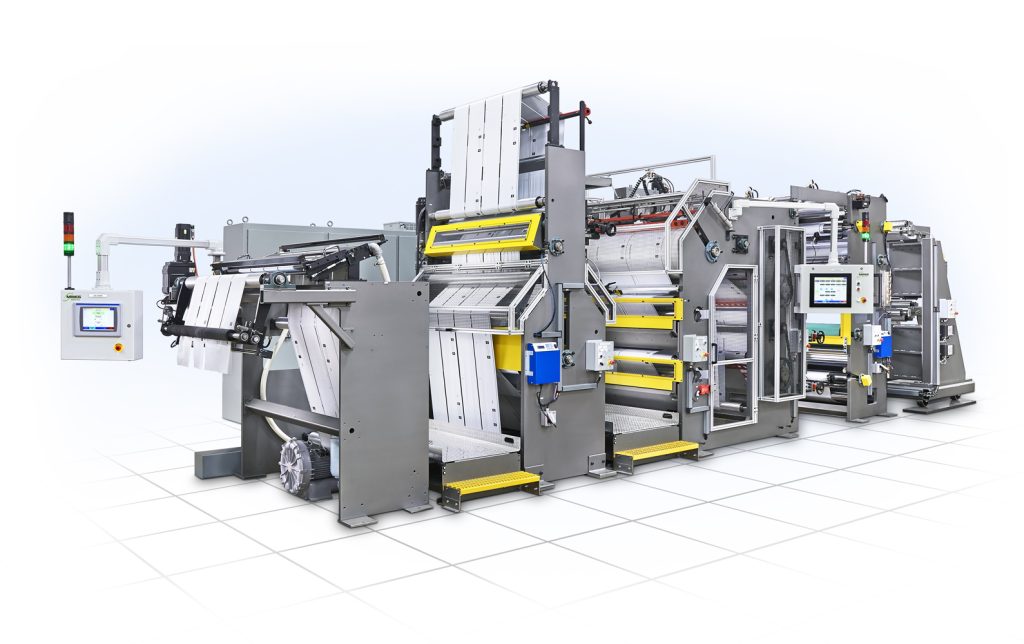

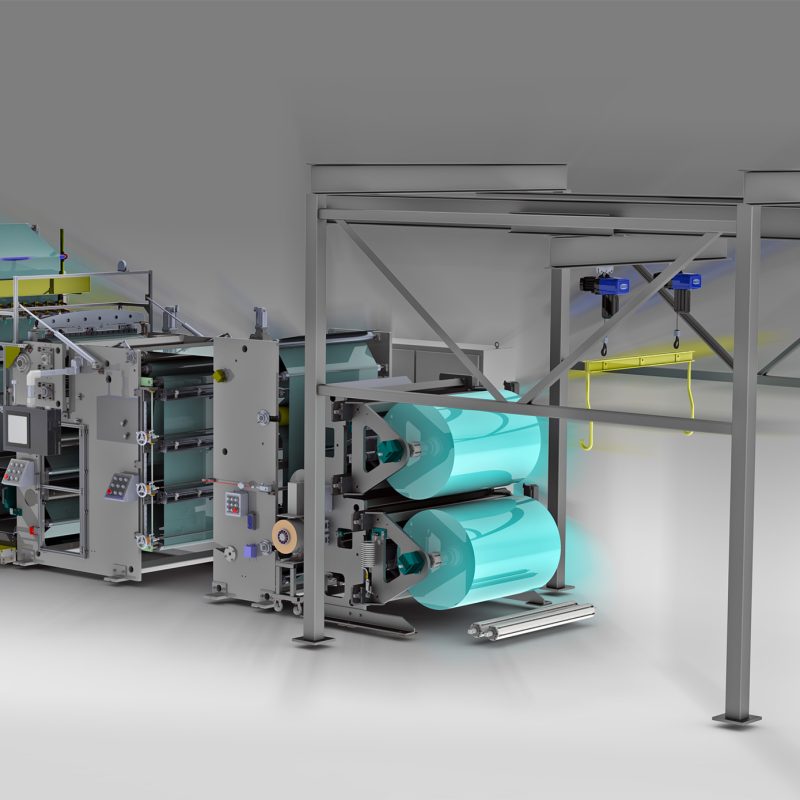

Midwest Engineered Systems automates ultrasonic thermoplastic welding processes in any situation. From small stand-alone systems to large robotic integrated processes, MWES custom designs each ultrasonic welding system for your specialized process needs. Backed by extensive knowledge, experience and certifications, our expert professionals can deliver specialized service whether you need a custom fabricated plastic part or an onsite repair of your current ultrasonic welding system. Automated ultrasonic thermoplastic welding systems are offered in a variety of capability ranges depending on your plastic welding needs, whether the parts are simple or have complex geometries.

Welding with ultrasound combines thermoplastics using the heat created through mechanical actions that operate at a high frequency. Electrical energy with high frequency is produced and is converted into this high-frequency mechanical motion. The applied force is used in conjunction with a mechanical motion to produce heat friction at the mating surfaces or joint areas of the metals or thermoplastics. This heat friction causes the parts to melt together, forming a molecular bond that is strengthened once the materials cool back down. The welding process can be supplemented with a plastic filler rod that is similar to the plastics being welded together.

The benefits of ultrasonic welding are that it produces lower production costs, creates a very effective bond with a high-quality seal that doesn’t require fillers, and has faster welding times than most other traditional welding procedures. By conducting thorough process analysis, manufacturers can ensure that their ultrasonic plastic welding systems are safely operating at peak efficiency, producing high-quality products while minimizing waste and costs.

Building the future of manufacturing, together

World-class Automation