Automated Weld Inspection

- Home

- Industrial Automation Capabilities

- Robotic Welding

- Automated Weld Inspection

Inspect Your Welding process with Automated Inspection Systems

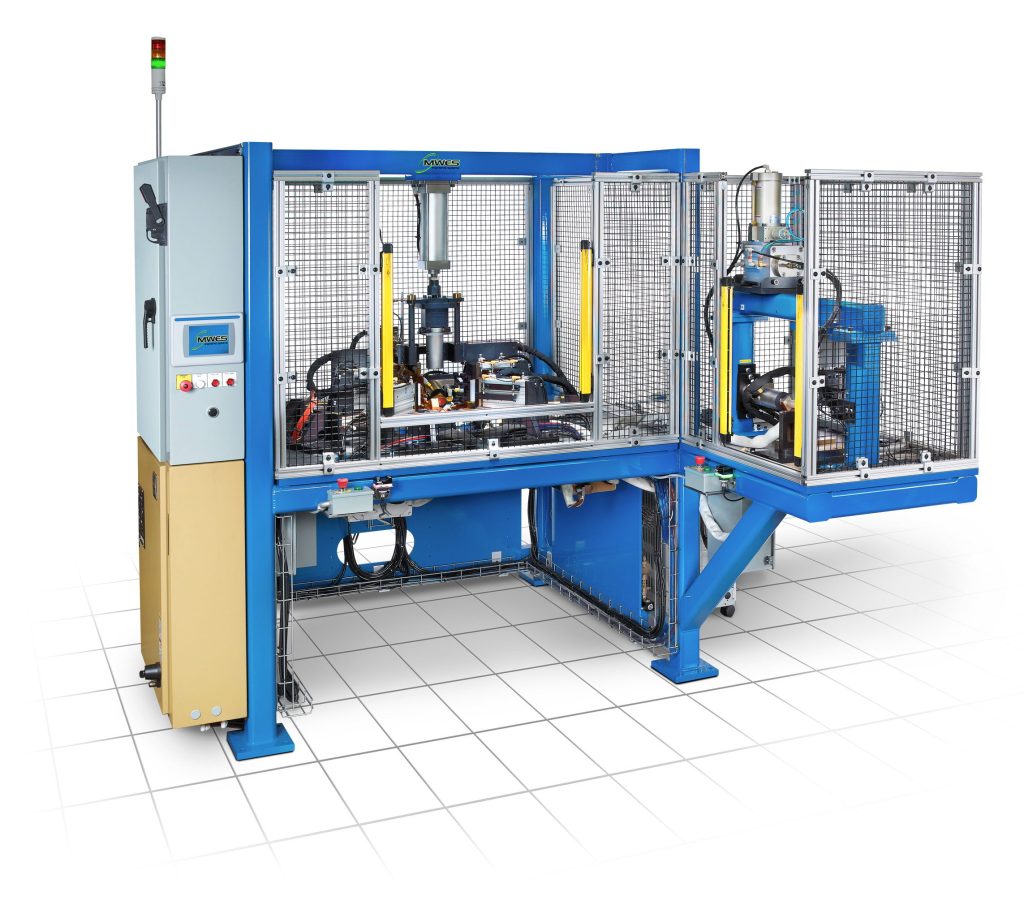

Midwest Engineered Systems offers automated weld inspection capabilities both as standalone systems and integrated into larger welding and manufacturing operations. The processes MWES uses to analyze welds are non-destructive and are most times able to detect weld issues faster and with more repeatable accuracy than human inspectors.

Automated weld analyzing systems can be integrated into robotic welding cells to track weld performance in real-time or the inspection process can be completed as its stage after the weld is complete. Many times, these systems can use the same robot used in the welding process. This can reduce costs and programming time.

Weld quality inspection can also be done purely as an inspection operation where previously welded assemblies can be analyzed for quality after arrival from subcontractors or before other assembly stages. These inspection systems can sometimes be used to analyze weld quality in locations where humans may have difficulty properly assessing, like tightly enclosed spaces.

Automated weld inspection systems not only check the weld geometry, including the weld length, shape, volume and weld alignment, these systems can detect defects in the weld that may occur. Advanced systems can identify spatter, burn-through, undercutting and porosity issues.

Midwest Engineered Systems is an integrator fluent in a variety of vendor systems and weld inspection technologies. Leveraging our experience in robotic welding, trust MWES to select the best inspection system for the production tasks at hand, regardless of vendor.

If you’re looking into automating welding or weld inspection processes, contact MWES today to speak with our highly experienced welding and machine inspection engineers to learn how your process will benefit.

Building the future of manufacturing, together

World-class Automation