Resistance Spot Welding

- Home

- Industrial Automation Capabilities

- Robotic Welding

- Resistance Spot Welding

We Automate Resistance Welding

Electric Resistance Welding is a quick, clean and efficient process for joining multiple sheets of metal and is capable of high-volume production applications. Resistance welding also allows for both similar and dissimilar materials to be welded together with no shielding gasses, solvents or fluxes. Moreover, it’s a simple low-cost process that is easily integrated with automation systems and robotics and does not demand pre-service welding training for the operator. Lastly, in resistance welding heat is concentrated and heat input intervals are short and is a cleaner, less-polluted work environment.

Resistance Spot Welding (RSW)

Spot welding is the most frequently used type of resistance welding process as it is fast, simple and widely applicable. The welded joint is formed by pressing electrodes at welding locations and focusing proper current and heat to specified spots on the materials to be joined. Spot welding can be easily automated and is extensively in the automotive industry for the production of car chassis parts and other large components. Automated robots can easily ramp up production by carrying out dozens to hundreds of spot welds within seconds depending on the weld components. Spot welding is frequently used in the manufacturing of metal furniture and other consumer products.

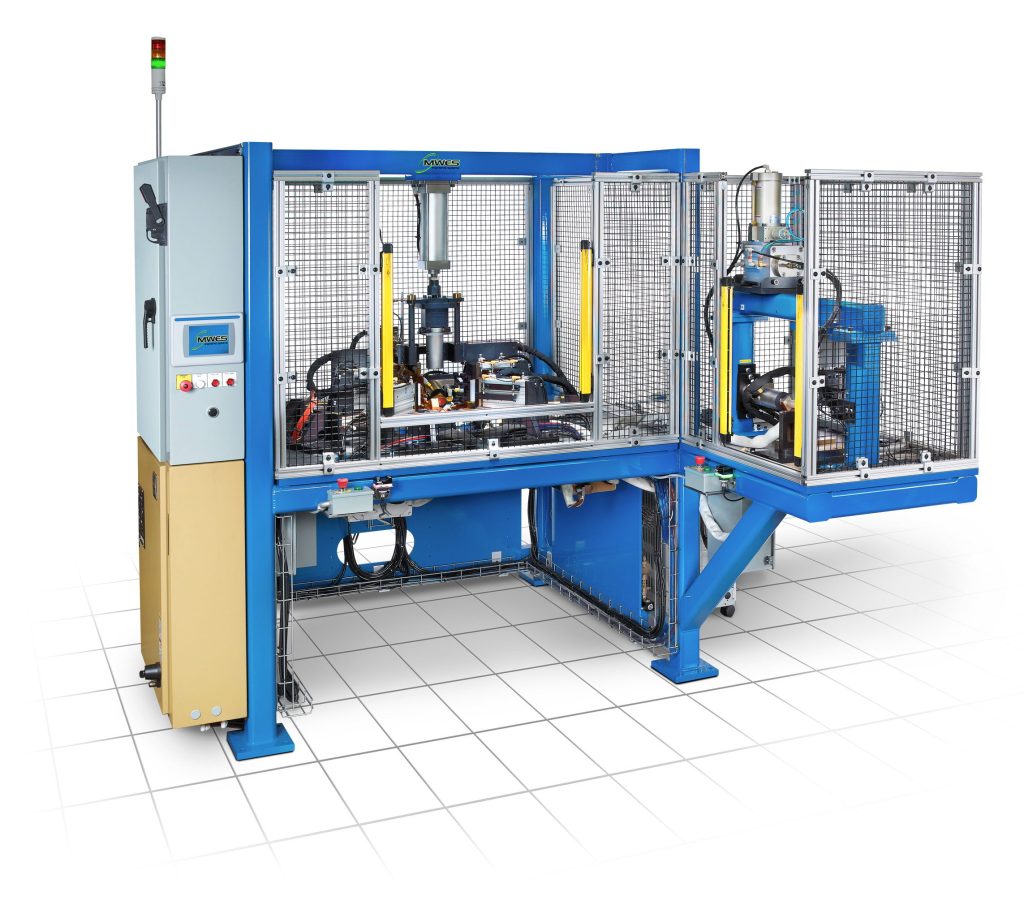

Resistance welding is widely used in applications in the metal fabrication and manufacturing industries. Midwest Engineered Systems has produced automated resistance spot welding solutions for many manufacturing firms. From small standalone systems to fully robotic automation, MWES custom designs each welding system for the customer’s specific needs. If your welding operation requires automation then contact us today.

Building the future of manufacturing, together

World-class Automation