Weld Upgrades & Retrofits

- Home

- Industrial Automation Capabilities

- Robotic Welding

- Weld Upgrades & Retrofits

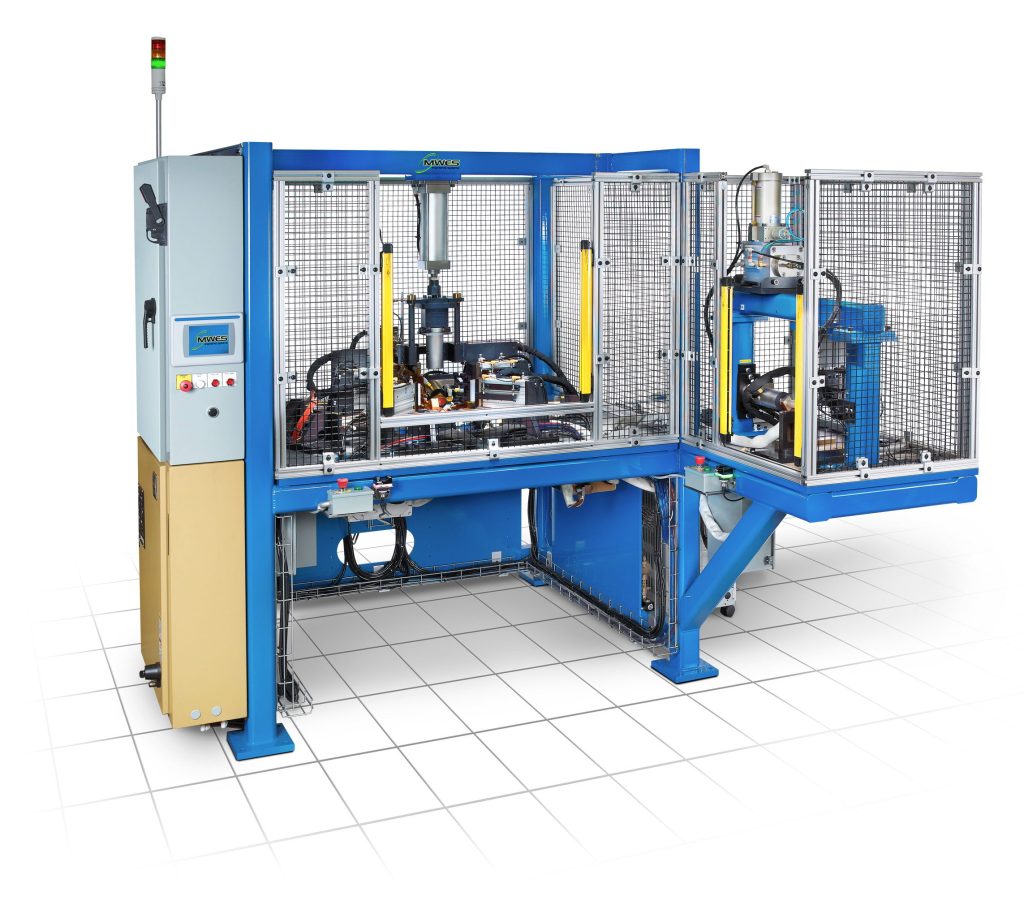

Upgrading & Retrofitting Your Welding Operation

Robotic automation and welding technology are advancing with new features and capabilities every day. Newer technology has the potential to improve equipment reliability, weld quality and overall throughput for your operation, with an incredible return on investment (ROI) for your business. Upgrading and retrofitting a welding system can improve its performance, efficiency and safety. However, it is not a simple task and requires careful planning and execution.

Steps MWES takes in upgrading and retrofitting a welding system:

- Assess the current state of the welding system and identify the areas that need improvement or replacement

- Assist in choosing the appropriate upgrade or retrofit options based on the welding system’s specifications, requirements and budget

- Obtain the necessary equipment, materials and tools for the upgrade or retrofit project

- Install, test and calibrate the new or modified components of the welding system

- Document the changes and update the maintenance and operation manuals

Midwest Engineered Systems can help you decide to replace, upgrade, or re-purpose existing welding automation components easily by upgrading only the obsolete components while retaining the functional equipment. We can also provide part and system programming for new products on your existing robot welding system. If your business is looking to retrofit or upgrade an existing automated weld system then contact us today.

Building the future of manufacturing, together

World-class Automation