Blog & News

Check out the latest from MWES

Categories

How Robotic Automation Can Reduce the Looming Impact of the Second Wave of Inflation

As the global economy continues to navigate the uncertainties of the post-pandemic era, concerns about a second wave of inflation are mounting. A second wave will significantly impact manufacturers, increasing production costs and squeezing profit margins. An innovative solution that will help mitigate the effects of inflation is the adoption

Automating the Modifications to Fully Built Military Equipment

Upgrading and enhancing the effectiveness of an entire line of fully built heavy military equipment requires careful planning and execution. The modification process is even more complicated by the hardened heavy armor shell that military vehicles are built around. The production line needs to operate quickly and efficiently to get

The Evolution of Industrial Automated Control Systems

In the realm of industrial manufacturing, the rise of industrial automated control systems has been nothing short of revolutionary. These systems, which encompass a broad range of hardware and software, are designed to enhance automation efficiency, precision and reliability in various industrial processes. Without them, the automation we take for

How Lights-Out Manufacturing is the Future of Manufacturing

Lights-out manufacturing is not a fantasy, but a reality that is becoming more common in the manufacturing sector. It requires the support of various technologies, such as machine learning, cloud data, machine vision and robotics. These technologies allow machines to communicate with each other, monitor the production process and perform

The Demographic Cliff: How AI and Automation are Filling the Gap

Baby boomers are reaching retirement age in large numbers, which means a significant portion of the workforce is leaving their jobs. This has led to concerns about a potential labor shortage, especially in industries that traditionally rely on skilled and experienced older workers, such as healthcare, manufacturing and skilled trades.

MWES is Ready for Industry 4.0

Industry 4.0 is used to describe the Fourth Industrial Revolution, which is characterized by the integration of digital technologies, such as artificial intelligence, cloud computing, big data, and the Internet of Things (IoT), into the manufacturing processes. One of the main benefits of the introduction of Industry 4.0 into robotics

Upgrade Your Old Manufacturing Operation with New Automation

Many businesses rely on machines that are decades old, and those machines develop a great deal of wear and tear over time. Maintenance costs and down-time for repairs can be a costly expense and severely hinder production line throughput. An automotive parts manufacturer came to Midwest Engineered Systems afflicted with that very problem.

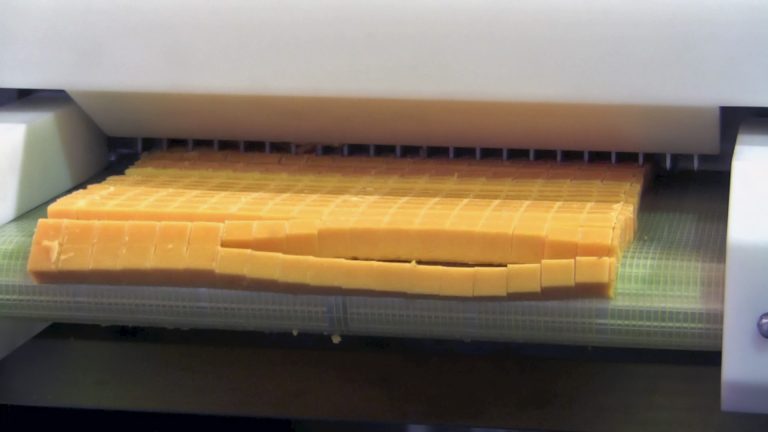

Expand Your Existing Automation with MWES

As your business grows, so will the demands on your manufacturing throughput. However, if the original manufacturer of your existing automation system is no longer in business, you will be forced to look elsewhere to expand your automation throughput. A leading national cheese supplier came to Midwest Engineered Systems with that very problem.

Are your products ready for manufacturing?

Knowing exactly how tight tolerances need to be can go a long way in reducing production system costs. Over-specifying tolerances will move integrators from more cost-effective machines to expensive, highly-specialized equipment.

Manual Production Line Updates for Increased Throughput – No Automation Needed

Whether the human-centric production process revolves around high dexterity operations or large scale, heavy industrial applications, greater efficiency can be found by adopting systems used primarily in automation-first systems. Many times, production volume increases can be had without resulting in replacing workers with automated processes and can even be installed without large disruptions to current production.