Blog & News

Check out the latest from MWES

Categories

Enhancing Data Center Construction with Robotic Welding Solutions

In the rapidly evolving digital landscape, data centers are the backbone of global information storage and processing. The construction of these facilities demands precision, efficiency, and scalability. Robotic welding has emerged as a pivotal technology in meeting these demands, offering unparalleled advantages in the assembly of data center infrastructures. The

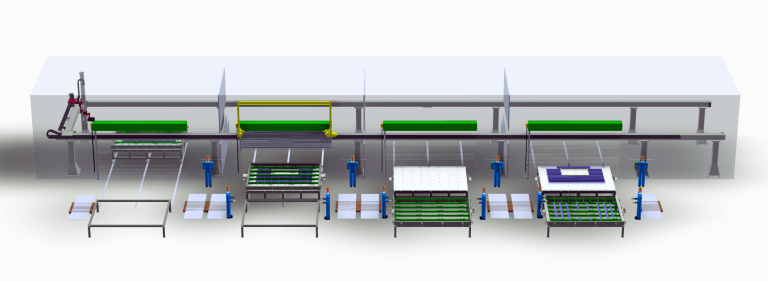

Project Spotlight: Welding and Milling Bus Bars Robotically

With the current ongoing labor shortage, skilled welders are in short supply leaving many businesses to rely more heavily on robotics to fill that void. Fully automating a 24/7 welding operation is not as complicated or as intimidating as it may sound. What if the production line requires multiple stations or has to handle different metal types?

Project Spotlight: Rail Car Assembly

When you’re riding on the subway, most people don’t think about how the car they are riding in was assembled much less the process behind it. MWES built a robotic welding system that would allow a single robot on an overhead gantry to work in tandem with human workers safely.

What’s on our floor: SkyHook extra-large positioners

Automation systems come in a variety of sizes. Some are small enough to process sensitive medical operations. They scale up from there to robotic systems that can process parts the size or weight of a car and beyond.

How to know if robotic welding is right for your application

Knowing when to automate processes can be a tricky prospect. When looking at replacing a highly skilled, yet difficult to fill human operation like production welding with robotic systems, the question can become even more murky.

Welding Large Assemblies with Robotics

Welding together complex assemblies of numerous components can be done with automation – and without massive investments in systems and workforce to make it go. Many times, with proper weld fixtures, even loading and unloading the process doesn’t require a trained welder.