Easy-Arc Custom Welding Cells

- Home

- Industrial Automation Capabilities

- Robotic Welding Systems

- Easy-Arc Custom Welding Cells

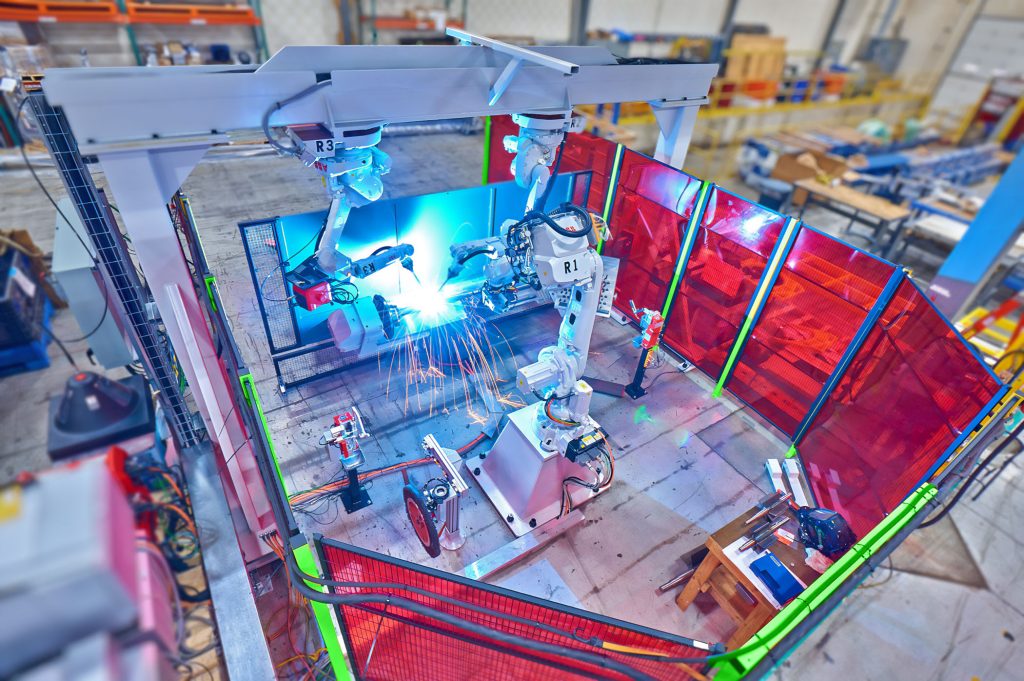

Complex Welding Solutions Require Custom Built Robot Systems

At Midwest Engineered Systems, our team of welding automation specialists has more than 30 years of experience. Our expertise and experience lie in welding design, development and programming, and we call on these abilities when creating our custom cutting-edge automated weld cells. We construct our custom weld cells for a variety of industrial welding applications which provides us with the knowledge and experience to apply a solution that is right for all of the very different welding requirements of our customers. As such, we continuously strive to develop our approaches to automated welding to better accommodate customers from all industries.

Advantages of robotic welding

Transitioning to automated welding from manual processes has several advantages. Automated robotic welding is much more efficient and much more consistent than manual welding operations. Manual welding has traditionally required the training of skilled technicians as well as the technicians’ ability to consistently produce quality welds. However, with automated welding options that are customized to your exact production needs, you can rely on machine technology to produce a consistent product and eliminate the inconsistencies of manual welding.

MWES Custom Designed Weld Cell Projects

Learn more about our welding process and possibilities for custom-designed weld cells by viewing a few of our featured welding projects:

Robotic Welding & Positioner System

Pressure Vessel Head Welding Cell

Concrete Mixer Drum Welding Cell

Automated 3-Piece Pipe Weld Cell

Our Weld Cell Building Expertise

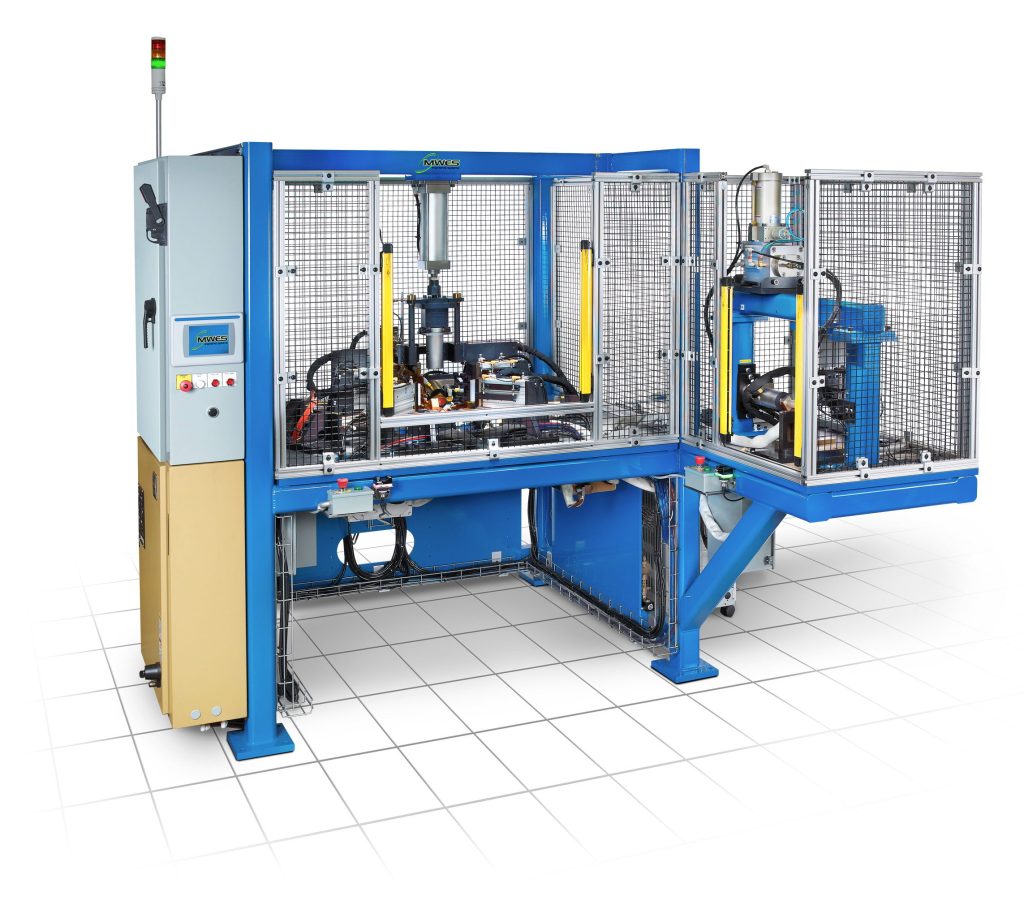

MWES has built complete, turnkey production line welding systems for a variety of manufacturing industries. This precise technology is a great welding option for low heat effect and thermal distortion control. We also employ laser welding on complicated, difficult-to-reach joint geometries. Laser welding is used where high travel speed is required. Due to the higher travel speed, less heat input is brought into the workpiece. Accurate part fit-up is required.

Our expertise and experience make us industry leaders in custom automation welding solutions. Our wide skill set includes automatic welding programming, robotic vision, adaptive welding and material handling. Using our expertise in these areas, we continuously develop and use the most advanced and modern welding technology.

For custom builds, we design, construct and implement specialized welding automation to meet your specific needs and requirements. Our designs are both tailored to your needs and will include all we have learned from our three-plus decades of experience building other weld cells. These decades of experience have afforded us the knowledge of what works, what does not and what needs refinement. We can offer a solution that will work best for your applications and needs.

Rely On MWES For Your Custom Welding Cells

Our custom weld cells can accommodate the needs of various manufacturing industries. We can custom-build an automated weld cell that is right for your operations and production requirements. To discuss transitioning to robotic welding for production welding operations, contact MWES today. You can speak with one of our skilled and knowledgeable Application Engineers to learn more.

Building the future of manufacturing, together

World-class Automation