Delta Robots

- Home

- Types of Industrial Robots

- Delta Robots

When Speed & Precision are Paramount

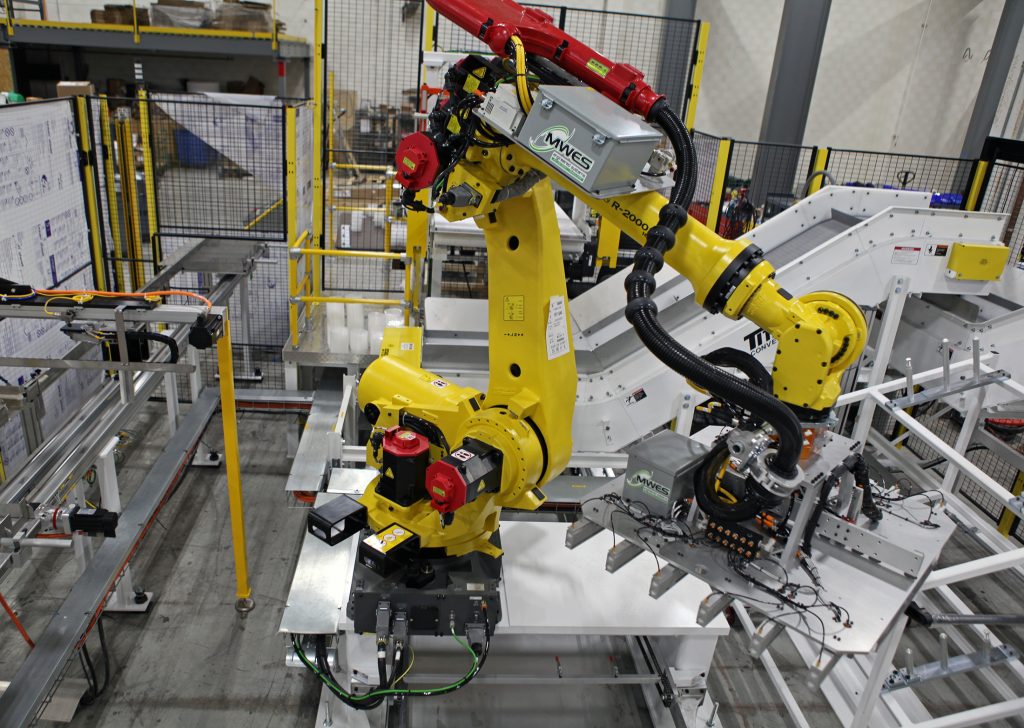

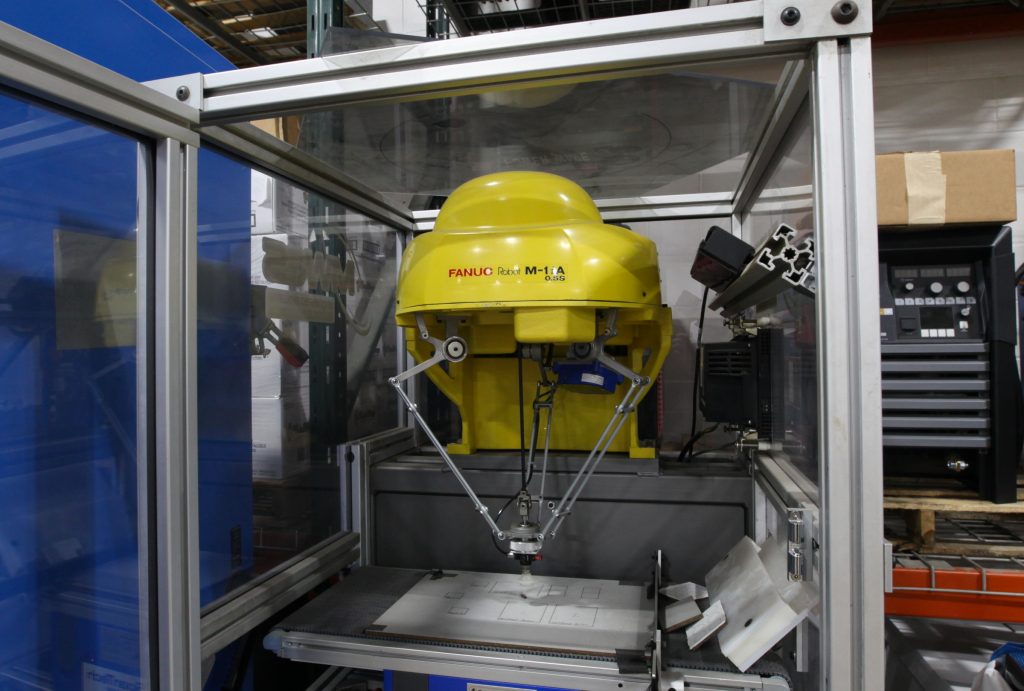

Delta robots, sometimes referred to as spider or parallel robots, are robots with a base connected to jointed parallelograms. These parallelograms perform motions in a solitary end of arm tooling (EOAT), within a workspace that is dome-shaped. This type of robot is well-known in the industrial field for its ability to execute minute, precise motions.

Delta robots are primarily operated when production is required for groups of objects and these objects must be placed in either an assembly pattern or inside of a container. With the addition of capable vision technologies, delta robots can properly identify and select a range of object colors, shape options and sizes. They can also use these vision technologies to pick and place working from a programmed pattern or design.

These types of robots can work with more than 100 parts per minute, picking, placing and sorting them much faster than manual labor processes are capable of performing. Their design allows them to very efficiently perform repetitive tasks at a highly consistent rate. A chief benefit of delta robots revolves around the fact that their relatively heavy motors are attached to the robot’s frame, permitting the robot’s moving parts to be very light by comparison.

Applications of Delta robots

- Automated case packing operations

- High-precision assembly processes

- Medical and pharmaceutical processes

- Food processing and handling

- Packaging automation

- Soldering operations

- Adhesive dispensing and placement processes

Contact Midwest Engineered Systems to learn how we can analyze your current production systems and develop a robotic automation system that increases productivity and efficiency!

Building the future of manufacturing, together

World-class Automation