The manufacturing sector in the United States faces a significant challenge that could shape the industry’s future. A recent study by Deloitte and The Manufacturing Institute projects that by 2030, the U.S. could see as many as 2.1 million manufacturing jobs go unfilled due to a skills gap. Additionally, businesses have reported that attracting and retaining talent is the biggest challenge for 65% of manufacturers in the U.S. This shortage could potentially cost the economy $1 trillion in the same year. With the industry already struggling to fill higher-paying skilled manufacturing positions, the need for a solution is essential.

The shortage is fueled by an entire generation of skilled workers retiring from the manufacturing and skilled trades workforce, and more businesses than ever are reshoring their manufacturing operations. The demand for skilled workers is greater than ever. However, the younger generations have not embraced the trades or have a desire to work in manufacturing in the same numbers as their parents and grandparents before them. These colliding forces have pushed manufacturers toward full robotic automation.

The Rise of Robotic Automation

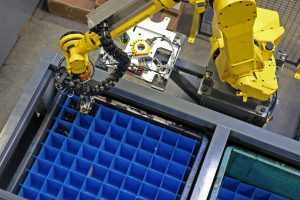

The transition to robotic automation is one of the most promising solutions to this looming labor crisis. Industrial robots have been a mainstay in specific manufacturing applications for decades, however, robots are now being sought after in every other manufacturing sector as well. Robotic automation offers a way to not only address the generational skills gap but also to enhance efficiency, productivity and long-term cost savings.

Robots can increase the efficiency of a manufacturing operation by operating continuously 24/7 without the need for breaks or pauses in the production line, leading to higher output rates. Robotic automation also produces highly accurate results and unparalleled precision, ensuring consistent product quality where human error is eliminated. The investment in robotics can lead to significant savings in labor costs and worker procurement, with manufacturers who have made the transition to robotic automation typically seeing a return on investment within 24 months.

What MWES does for automating your process

The potential for half of the new U.S. manufacturing jobs to go unfilled in the next decade presents a stark reality for the industry. However, by embracing robotic automation, manufacturers can not only head off this challenge but also position themselves for future growth and competitiveness. The transition to a robotic workforce is not without its risks, but when you work with Midwest Engineered Systems those risks disappear.

Contact us today and let MWES’s vast industry experience help sustain your manufacturing throughput. MWES is ready to transform your industrial operations with robotics that will provide superior perception, integrability, adaptability and reliability for years to come.