Midwest Engineered Systems has spent decades improving our customers’ factory automation processes with robotic automation systems. By moving to robotic automation, those firms benefited from having a sizeable return on investment (ROI) and greatly improved throughput in their factory operations, all the while not being burdened by the labor shortages that are currently affecting manufacturing.

How MWES can improve your factory automation with robotic production systems

To start factory automation uses technology to automate processes in industrial settings, such as warehouses and manufacturing facilities. Factory automation can improve productivity, quality, efficiency and safety by reducing costly human intervention and errors. One of the key technologies that enable factory automation is robotic production systems.

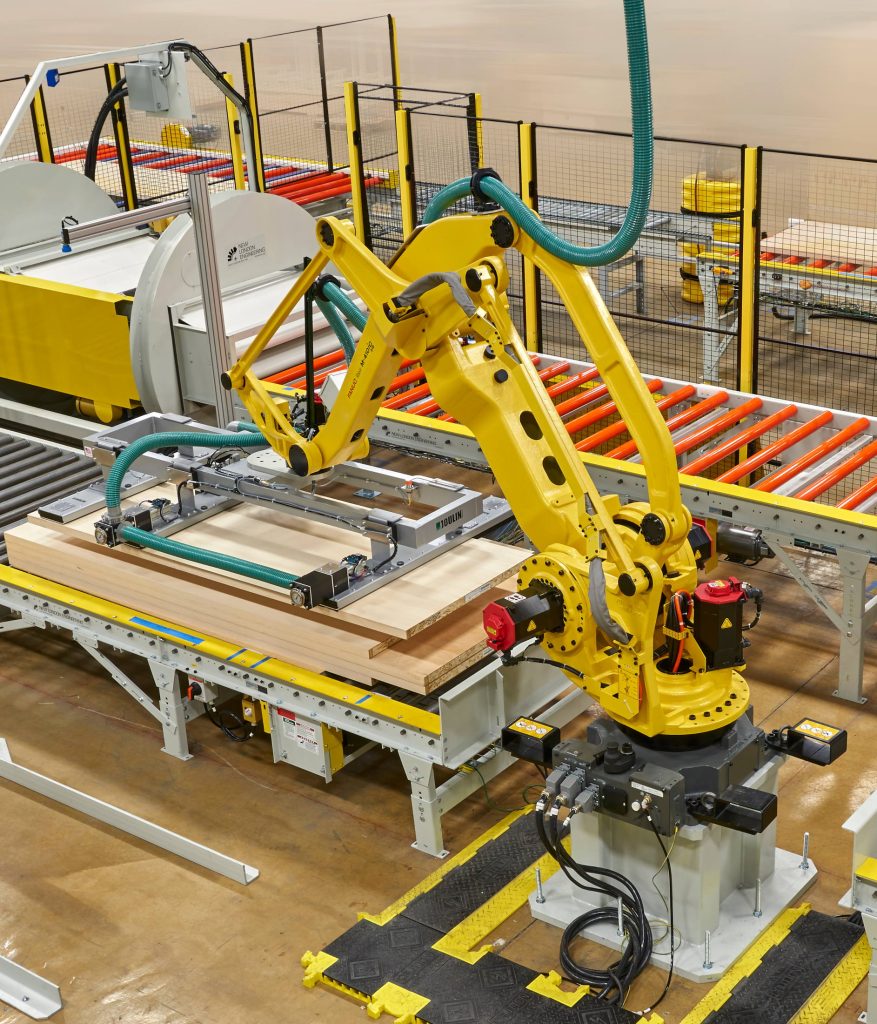

Robotic production systems use robots to perform tasks that are repetitive, consistent, dangerous or require high precision. Those robots can be classified into two main types: Automatic Guided Vehicle (AGVs) and industrial robotic arms. AGVs are robots that can move freely in a warehouse or factory, without following predefined paths or relying on human guidance. They can assist human workers with tasks such as material handling, picking and placing and part sorting. Industrial robots use end effectors (or EOATs) to perform tasks such as welding, grinding, picking, assembling and part inspecting.

Both types of robots use artificial intelligence and machine vision to perceive and understand their environment and to plan and execute their actions. They also use sensors and actuators to communicate with other robots and devices in the factory automation system. For example, an AGV can use a camera to scan a barcode on a package, and then use a wireless network to send the information to a central control system that assigns it a destination. An industrial robotic arm can use a force sensor to detect the resistance of an object, and then adjust its pressure accordingly.

Factory automation with robotic production systems can benefit a wide range of operations, large and small. It can increase the flexibility of production processes, allowing for faster adaptation to changing customer demands and market conditions. It can also reduce labor costs that are the result of worker shortages, by replacing or augmenting human workers with robots that can work 24/7 without fatigue or injury. Moreover, robots can enhance product quality and consistency, by eliminating human errors and variability in operating performance.

What are your next steps?

Ultimately this is where Midwest Engineered Systems comes in, factory automation with robotic production systems is not an absolute solution for every business. It requires careful planning, evaluation and implementation to ensure that it meets each business’s specific needs and goals. It also requires constant monitoring, improvement and innovation to keep up with the rapid advances in robotics technology. MWES is a certified robot integrator and has decades of experience in robotic factory automation. Our experts can analyze your operations and produce a robot-integrated solution for your business that will give you a substantial return on investment.

Contact us today and speak with one of our Applications Engineers and see if robotic production systems can improve your factory automation. We can help guide you through the process and ensure a solid return on investment for your business.