Frontloading inventory is a strategy that can lessen tariffs’ damage to your business.

Tariffs can significantly impact a business’s supply chain, leading to increased costs, disrupted production schedules, and strained supplier relationships. Companies should proactively manage inventory to reduce risks and ensure enough stock for potential tariff increases. This is where robotic automation comes into play, offering a powerful solution to streamline inventory processes and enhance overall efficiency.

Adopting robotic automation is one of the key strategies to mitigate such risks and optimize inventory management. By leveraging advanced automation equipment, businesses can effectively manage and frontload inventory, ensuring they are better prepared for potential tariffs and international trade disruptions. Robotic automation can revolutionize your inventory management and help you stay ahead of the curve while maximizing efficiency and reducing costs.

How Robots Can Manage Your Frontloaded Inventory

Automated Warehousing and Storage Solutions

Industrial Robotic automation can revolutionize warehousing and storage by automating repetitive tasks such as picking, packing, sorting and palletizing. Automated guided vehicles (AGVs), conveyors, and AS/RS systems can efficiently transfer, organize and store inventory within the warehouse, reducing the need for costly labor and errors. This increased efficiency allows businesses to frontload inventory, ensuring they have adequate stock to meet demand despite tariffs.

Real-Time Inventory Tracking and Management

One key advantage of robotic automation is providing real-time visibility into inventory levels. Automated systems equipped with vision systems and QR code scanners can continuously monitor stock levels, ensuring accurate and up-to-date information. This real-time tracking enables businesses to decide when to frontload inventory, avoiding shortages and overstocking.

Maximize Warehouse Floor Space

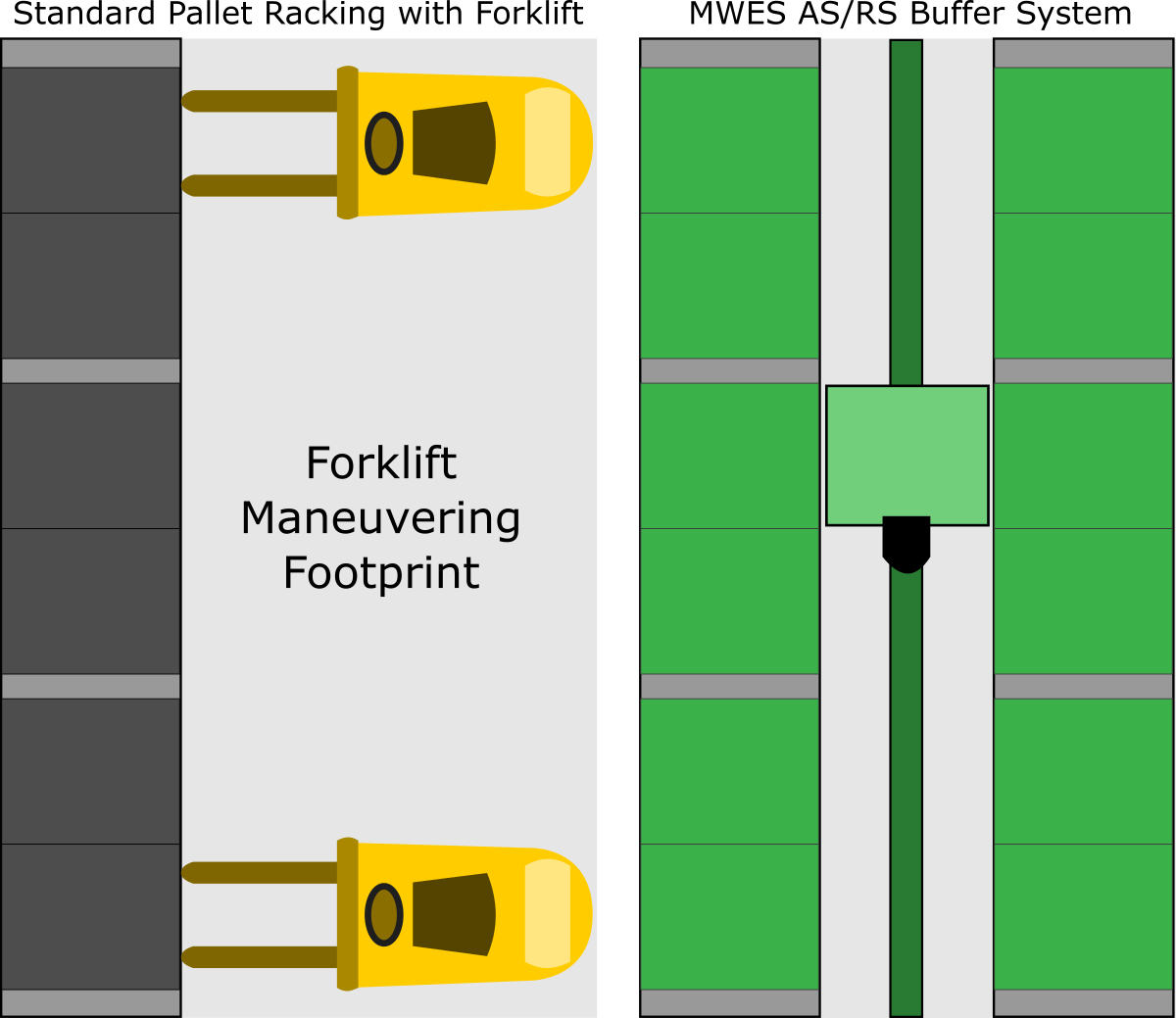

AS/RS systems and AGVs require less floor space and narrower aisles to operate than typical pallet racks with manned forklifts. This will free up floor space, allowing for more racking or other equipment to be installed. Additionally, these systems operate safely with minimal human intervention.

Predictive Analytics and Demand Forecasting

Automated systems can accurately predict future demand by analyzing historical data and market trends. This allows businesses to strategically frontload inventory, ensuring the right products and quantities are available to meet expected demand, despite potential tariffs.

Optimized Order Fulfillment and Delivery

Efficient order fulfillment and delivery are crucial for maintaining customer satisfaction and meeting market demands. Robotic automation can optimize the entire order fulfillment process, from picking and packing to shipping and delivery. Automated systems can quickly and accurately process orders, reducing lead times and ensuring timely deliveries. This streamlined process allows businesses to frontload inventory effectively, minimizing the impact of tariffs on their operations.

What Can You Expect from Frontloading with Robotic Automation

With fluctuating trade policies and tariffs, businesses must be proactive in managing their inventory to stay competitive and resilient. Robotic automation offers a powerful solution as part of your frontloading strategy. By adopting robotic automation, businesses can reap many benefits that directly contribute to their ability to frontload inventory in preparation for current or future tariffs:

- Increased Efficiency: Automation eliminates bottlenecks and reduces manual labor, leading to faster and more efficient inventory management processes.

- Cost Savings: By minimizing errors and optimizing workflows, robotic automation can significantly reduce operational costs, and allow businesses to invest more in capital.

- Enhanced Flexibility: Automated systems can easily adapt to changes in demand and market conditions, ensuring businesses can respond swiftly to tariff-related challenges.

- Improved Accuracy: Real-time tracking and predictive analytics ensure accurate inventory management, reducing the risk of stockouts or overstocking.

Midwest Engineered Systems knows what it takes to manage a warehousing operation by providing solutions that improve efficiency, lower costs and provide a return on investment. By embracing robotic automation, businesses can navigate the cost increases that come with tariffs ensuring they are well-prepared for whatever challenges lie ahead.

Contact us today and discuss with us the best options for your warehousing automation!