What Is Lights-Out Manufacturing?

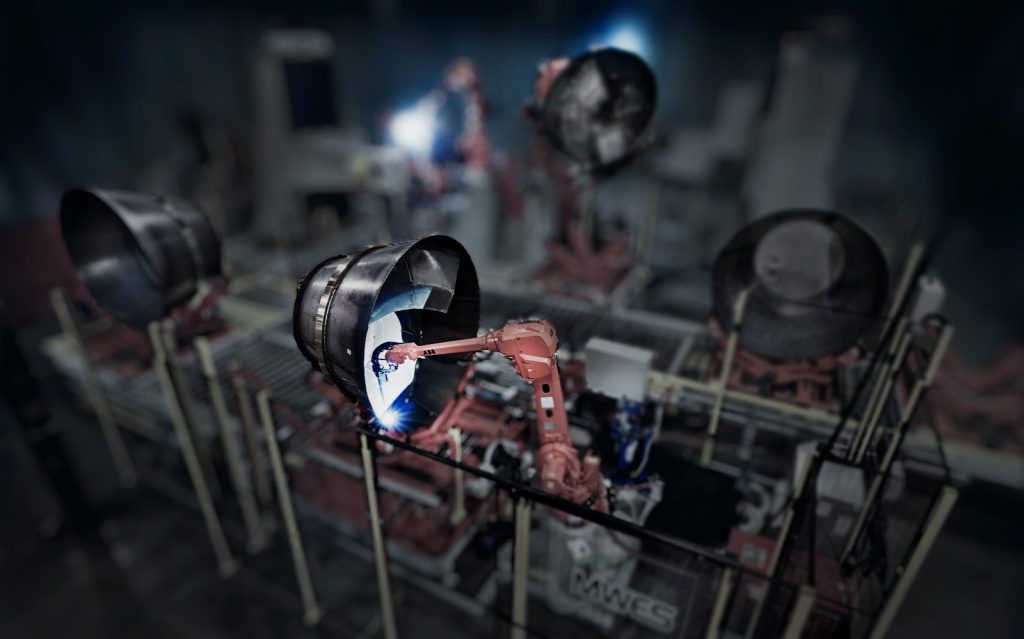

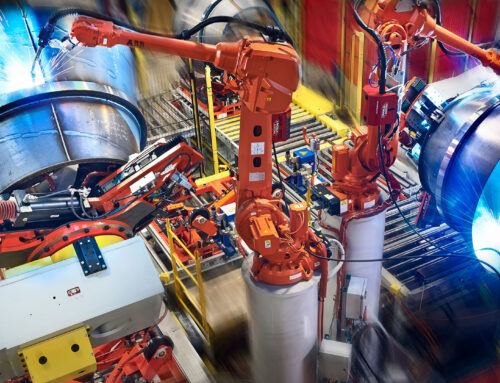

Lights-out manufacturing refers to fully automated production systems that operate autonomously with minimal or no human intervention. These “dark factories” run continuously, even without lighting, leveraging advanced robotics, artificial intelligence (AI), and the Internet of Things (IoT) to manage operations around the clock.

Key Benefits

- 24/7 Operation: Machines can work continuously without the need for breaks, holidays, or shift changes, leading to increased throughput and efficiency.

- Labor Cost Reduction: By minimizing human involvement, companies can significantly cut labor costs, including wages, benefits, and training expenses.

- Enhanced Quality Control: Automation reduces human error, leading to more consistent product quality and fewer defects. Tectron Metal

- Improved Workplace Safety: Robots can perform hazardous tasks, reducing the risk of workplace injuries and exposure to dangerous environments. E

- Sustainability: Automated systems can optimize energy usage and reduce waste, contributing to more sustainable manufacturing practices.

Challenges to Consider

- High Initial Investment: The setup costs for lights-out manufacturing systems can be substantial, including expenses for equipment, software, and facility modifications.

- Technical Complexity: Implementing a fully automated system requires advanced technical expertise and integration of various technologies.

- Limited Flexibility: Automated systems are typically designed for specific tasks and may struggle to adapt to changes in product design or production processes.

- Workforce Transition: The shift to automation may lead to job displacement, necessitating retraining and reskilling programs for affected employees.

Real-World Examples

- FANUC: A Japanese robotics company that has operated a lights-out factory since 2001, producing robots that build other robots autonomously for up to 30 days without human intervention.

- Xiaomi: In China, Xiaomi’s “dark factory” produces smartphones entirely through AI-driven automation, operating 24/7 without human presence.

The Future Outlook

As technology advances, lights-out manufacturing is becoming more accessible to a broader range of industries. While initial costs and technical challenges remain, the long-term benefits of increased efficiency, reduced costs, and improved quality make it an attractive option for forward-thinking manufacturers. The integration of AI, robotics, and IoT is paving the way for the next generation of smart factories.

Conclusion

Lights-out manufacturing represents a significant shift in industrial production, moving towards fully autonomous systems that operate efficiently and safely. While the transition requires careful planning and investment, the potential rewards in terms of cost savings, productivity, and quality make it a compelling choice for the future of manufacturing.