Aerospace

Over 30 Years Understanding

Automation Systems for all things Aerospace

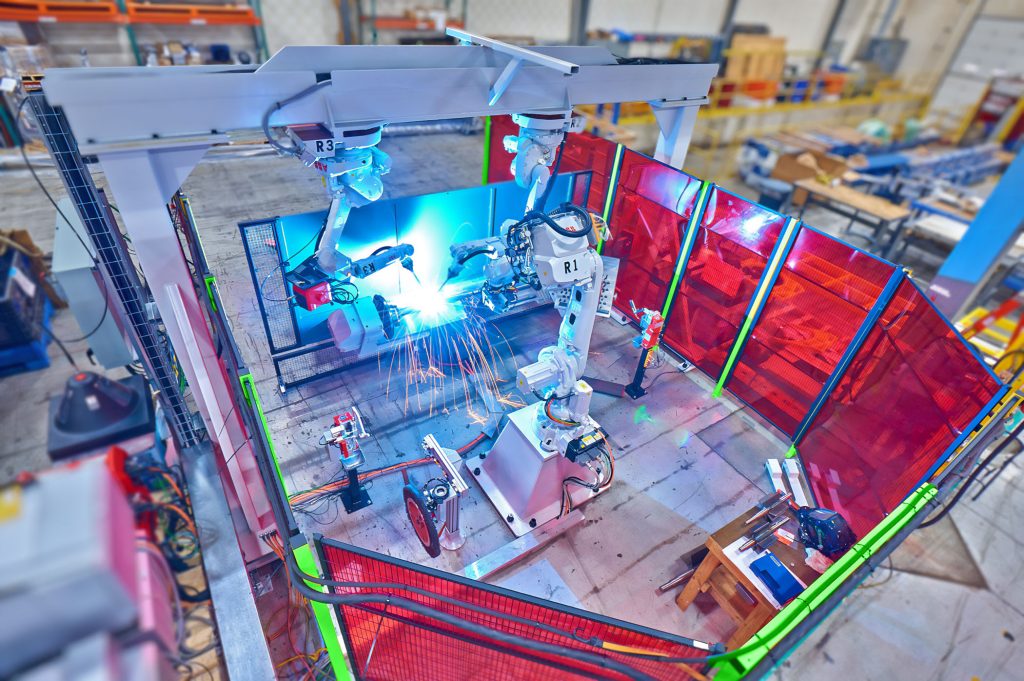

Robot automation is a key component in the aerospace industry, where precision, quality and repeatability are paramount in the construction of aircraft and space systems. These systems have to perform flawlessly as the room for failure is minuscule.

With the recent advent of metal additive manufacturing, or 3D printing, robotics has become even more instrumental in the aerospace industry. Additive manufacturing allows for the repeatable construction of complex superalloy parts that in the past would require skilled tradesmen to produce.

Midwest Engineered Systems meets all of the challenging demands of the aerospace industry. From high-precision automated manufacturing systems for high-performance power system assembly to building aircraft components with additive manufacturing, we have the experience necessary to design and integrate complex manufacturing systems and can take current processes to even greater heights all within our ITAR-compliant facility.

Automation Applications

- Large-scale Metal Additive Manufacturing

- Full Assembly Line Integration

- Part Assembly Systems

- Welding Operations

- Painting Operations

- Plasma Cutting Systems

- Material Dispensing and Placement

- Code Scanning and Traceability Systems

- Part Inspection and Testing Processes

Aerospace expertise

Engine Component Assembly Lines

Industrial Metal 3D Printing

ADDere Additive Manufacturing

ADDere is designed to manufacture large-scale industrial parts in some of the most challenging metal-based materials. With our internally developed control systems, the ADDere laser-wire systems are capable of 3D printing high-quality, near net shaped metal deposition with post-processing taken into consideration.

Building the future of manufacturing, together

WE Strengthen Industries through

Our Automation capabilities

Why work with us

A trusted partner in manufacturing

160+

Team Members

4,000+

Systems Built

198k+

Sq. Ft. Facility

12+

Years RIA Robot Experts

The Future of Manufacturing