Integrated Automation Systems

- Home

- Integrated Automation Systems

What are Integrated Automation Solutions

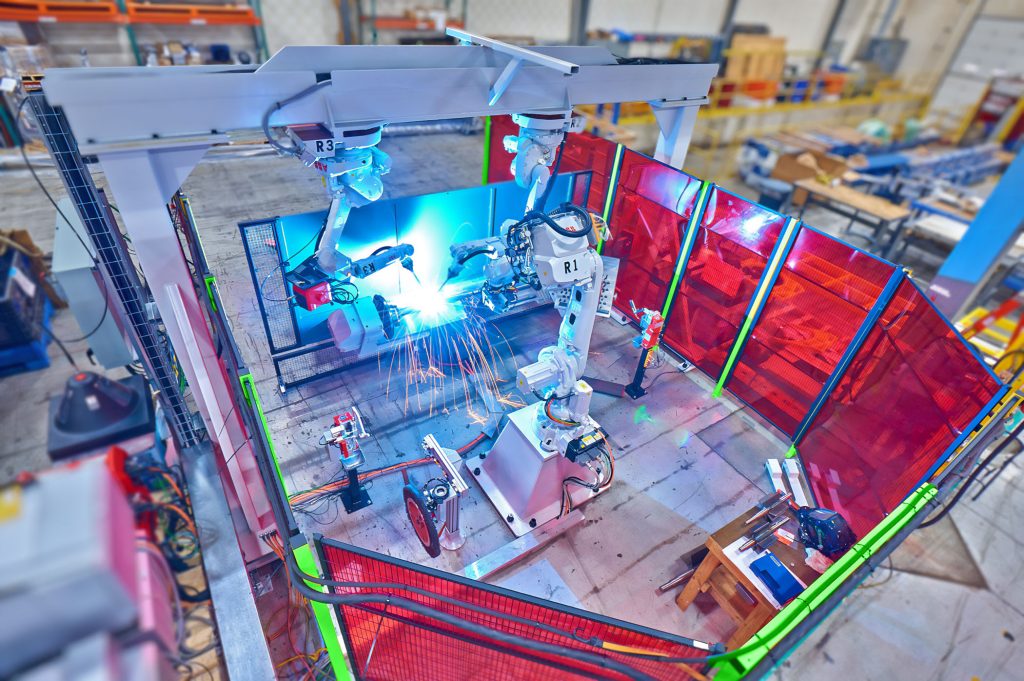

Integrated automation systems incorporate the total manufacturing system into a computer-controlled, digitally processed and coordinated system.

Integrated automation systems work through a common manufacturing system database. This central automation control point makes it possible to integrate industrial and non-industrial processes and robot integration through automated production technologies. Integrated automation systems are used in computer-integrated manufacturing and several types of advanced process automation systems.

A well-designed integrated automation system opens the door to implementing advanced technologies that could greatly increase efficiency and productivity across the entire manufacturing facility, including bringing together:

- Computer-Aided Process Planning (CAPP)

- Computer-controlled scheduling and production line control processes

- Manufacturing Execution System (MES) / Manufacturing IT integration

- Programmable Logic Controller (PLC) and Distributed Control System programming

- Coordinated Drive systems and advanced Motion Control

- Production Process Test Systems and Process Monitoring Sensors

- Part validation and Vision Inspection Systems

- Industrial Energy Management systems

- Automated material handling systems

- Automated retrieval and storage systems

- RFID and Bar Code part tracking systems

Contact Midwest Engineered Systems to learn how we can analyze your current production systems and develop a flexible automation system that increases productivity and efficiency!

Building the future of manufacturing, together

The Future of Manufacturing