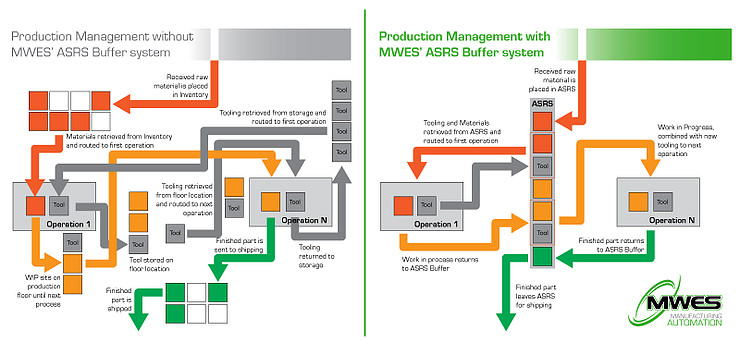

MWES’ Automated Storage and Retrieval (ASRS) system is designed to provide efficiencies found in automated warehouses to the demands of a production environment. These benefits are not just about storage, the system can become a highly efficient hub for managing manufacturing processes.

Our production-focused ASRS buffer system can return valuable manufacturing time, provide production data and reduce production errors. This provides a production environment with the ability to quickly manage materials as needed, as well as store tooling and work-in-progress in an efficient manner. The ASRS buffer system does this by cataloging materials and their locations by how they integrate into the production process.

Below is a quick list of material storage and monitoring capabilities advantages:

- The system can become a central hub for the factory: with both the tooling and materials in the same location and an overarching management system to run it.

- The MWES buffer system allows for the collation and management of asynchronous production processes

- The ASRS system helps keep production efficiency high by retrieving materials, tools and finished parts without needing human help.

- Material arrival and removal data can be harvested for production performance analysis

The system’s benefits provide the opportunity for a forward-thinking production facility to move to the next level of efficiency and productivity. Taking advantage of all these aspects makes the MWES ASRS production buffer system much more of a trusted workflow manager. It has the potential to better see the entire manufacturing process as a singular system, not just a collection of unconnected machines and resources.

Contact us today to learn how our ASRS buffer system can streamline your production operations.