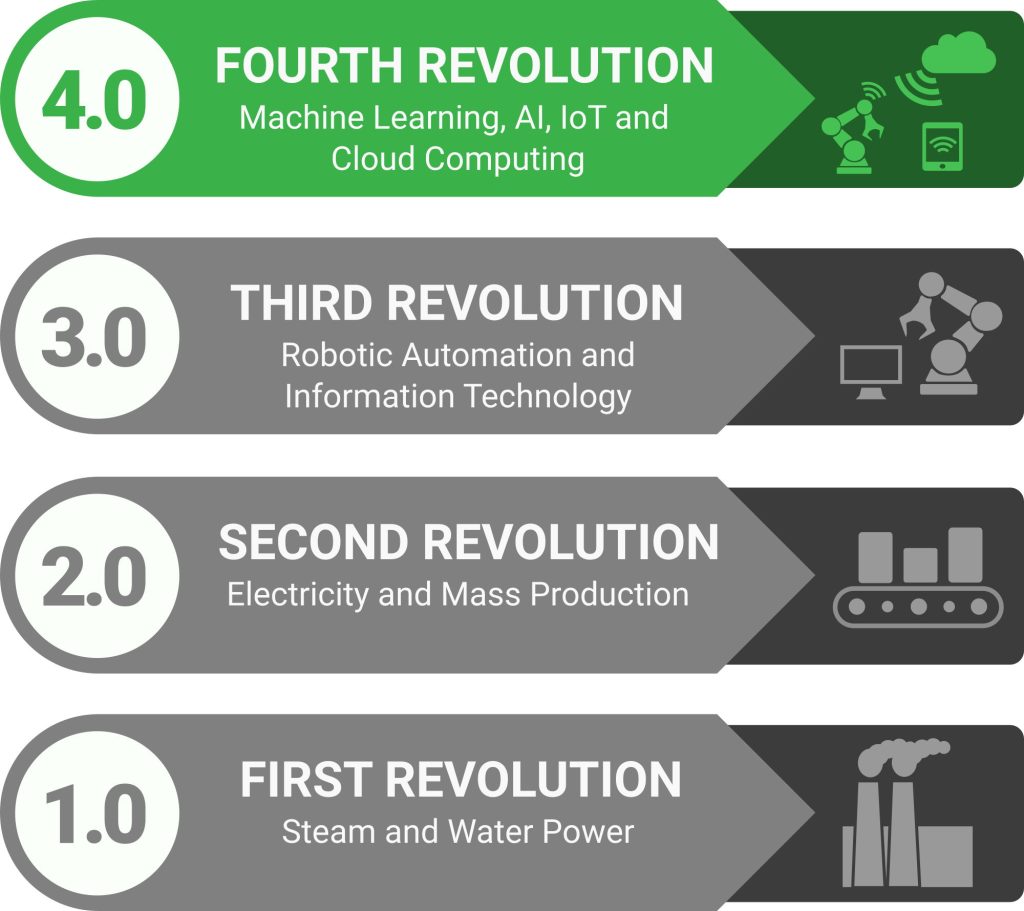

Industry 4.0 is used to describe the Fourth Industrial Revolution, which is characterized by the integration of digital technologies, such as artificial intelligence, cloud computing, big data, and the Internet of Things (IoT), into the manufacturing processes. One of the main benefits of the introduction of Industry 4.0 into robotics is that it enables a higher level of manufacturing automation and optimization of production systems.

Combining traditional robotic automation with Industry 4.0 technology creates new levels of visibility and insight by combining data from production operations with data from other enterprise systems. This helps manufacturers optimize their processes, reduce energy consumption, improve quality and safety, enhance customer satisfaction and create new business models. All of these things can help reduce costs and improve the overall bottom line.

In what areas does Industry 4.0 improve manufacturing

More specifically the technology that encompasses Industry 4.0 directly enhances robotic automation in manufacturing in these areas:

- Smart sensors and actuators collect and transmit data about the status and performance of the robots and their environment, enabling real-time monitoring, control, and optimization of the robotic processes

- Cloud computing and big data store and analyze large amounts of data from robots and other sources, providing insights and feedback for improving robotic operations and decision-making

- Artificial intelligence (AI) and machine learning enable robots to learn from their own experience and data, as well as from other robots and humans, improving their intelligence, autonomy, and adaptability

- Internet of Things (IoT) and cyber-physical systems connect robots with other devices, machines, systems and human workers, creating a network of smart systems that can communicate and cooperate, enhancing the flexibility and interoperability of the robotic systems

Industry 4.0 is revolutionizing the manufacturing industry and creating new opportunities for innovation and growth. By integrating the new digital technologies into the robotic processes, Industry 4.0 can enhance the capabilities, performance, and benefits of robotic automation for both businesses and customers. However, it will also require manufacturers to invest in new skills, training, security measures and technology to stay competitive and relevant in the global market.

Midwest Engineered Systems is an integrator at the forefront of robotic automation. We are dedicated to investing in Industry 4.0 technology and the best practices that will help firms make the transition to the next industrial revolution smoothly. Contact us today and let us guide you through the process of moving your manufacturing operations to the next level.