Consolidating Multi-Line Production Processes

- Home

- Our Process

- Consolidating Multi-Line Production Processes

Efficient Automation begins with

Analyzing and understanding your production facilities

When managing a large production facility, it can be difficult to find the time to step back and assess all operations in a way that process consolidation makes sense. There seems to be just enough time to focus on a single line’s processes and hope for immediate changes.

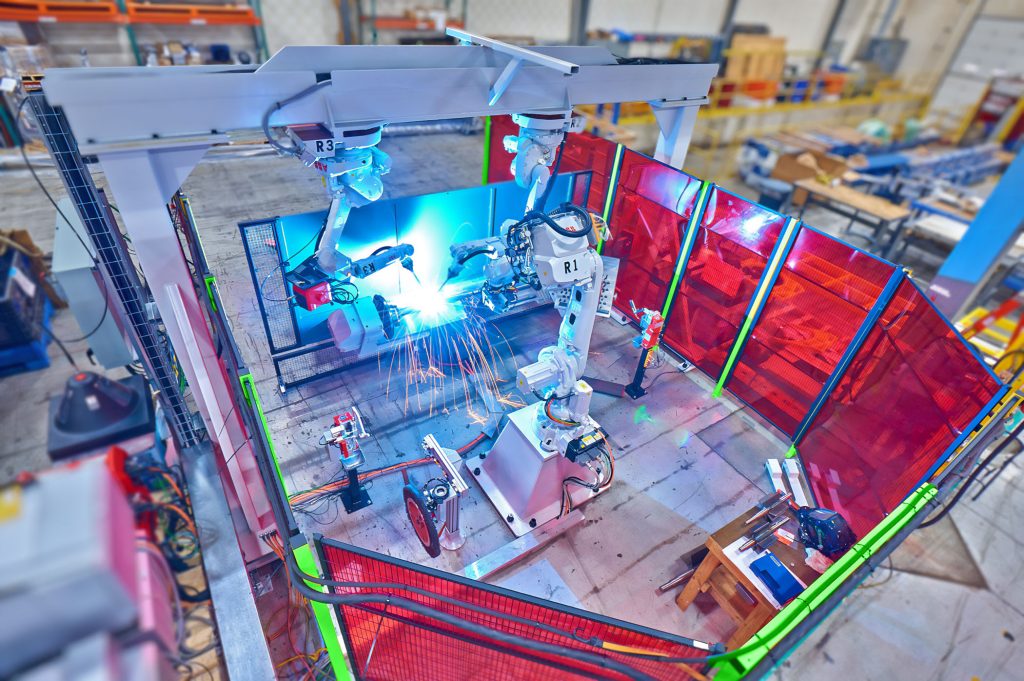

Trust Midwest Engineered Systems to be a partner in your pursuit of automation from the onset. We can utilize our depth of knowledge on facility-wide automation projects to analyze the current production system to build the best automation solution for not just a single line or operation but one that benefits the entire plant.

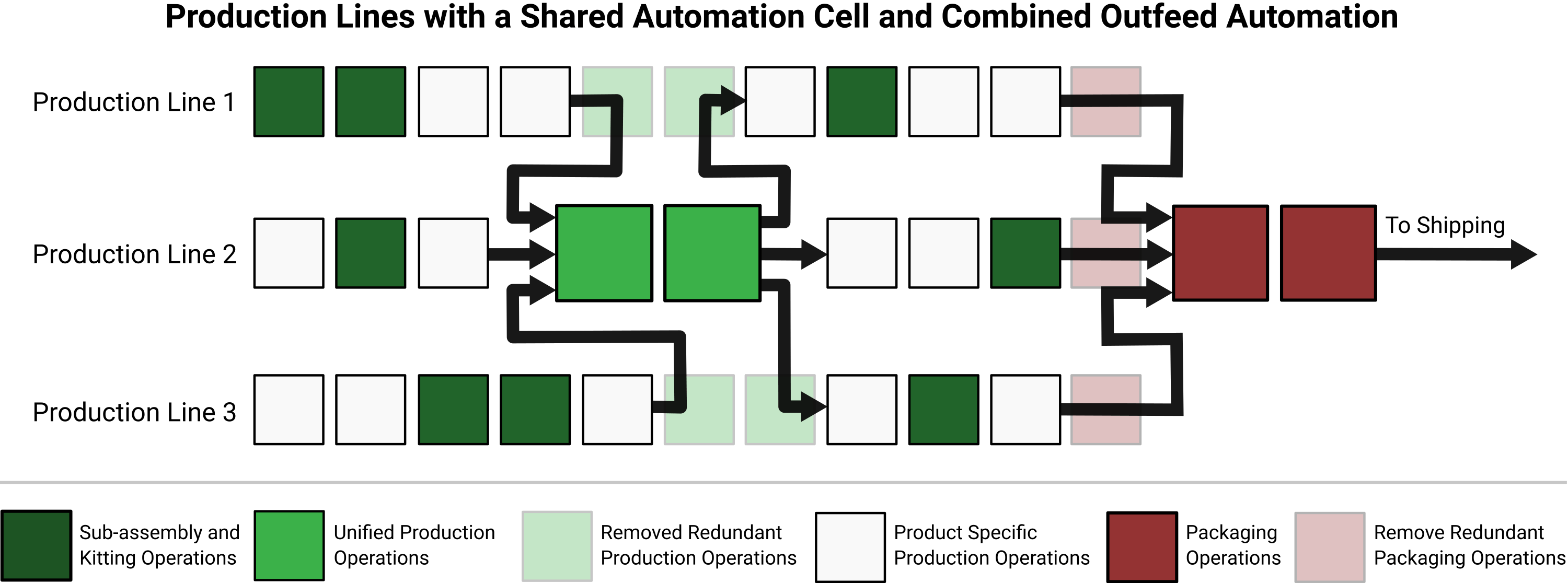

At MWES, we have decades of experience developing automation systems for entire production facilities. From our experience, it’s common to see opportunities in multi-line plants where consolidation of operations can bring about step-changes in throughput and efficiency – if you know what to look for.

Our whole plant analysis process involves understanding not just the separate manufacturing operations but how these activities and the components themselves overlap to find where synergies can be found.

It starts with an on-premises walk-through where our engineers can see the processes in operation. This level of detail is needed to understand the nuances of each step that can be easily left out of RFQs or operational summaries. From this and other information like system drawings and timing charts, we can build an accurate representation of how the entire facility operates. From here, we develop a whole system solution that reduces cost, waste and increases throughput.

As many firms may not have the ability to institute these changes at one time, MWES is highly experienced in dividing down the whole system solution into more manageable stages that can be instituted over time. This staged approach helps mitigate downtime, spread CapEx spending over time and produce efficiency wins that build upper management trust and sum over time.

Contact us today to learn more about the whole facility automation approach and how it can change the way you consider automation while leading to game-changing production gains.

Building the future of manufacturing, together

How we can help your business with

The MWES Process

Our Process

With each automation project, Midwest Engineered Systems implements a project management process that walks through the steps for successful equipment integration.

Process Development

Our approach to automation process development is to first evaluate the firm’s current production operation and understand the company’s process needs.

Proof of Principle Testing

We offer the ability to experience the performance of an automation system with real parts and production conditions before significant investment in a production automation system is made.

Consolidating Multi-Line Production

We can utilize our depth of knowledge on facility-wide automation projects to analyze the current production system to build the best automation solution.

Engineering for Manufacturability

We can help reduce the costs associated with automation by analyzing and suggesting product and process modifications.

Why work with us

A trusted partner in manufacturing

120+

Team Members

4,000+

Systems Built

100k+

Sq. Ft. Facility

12+

Years RIA Robot Experts

The Future of Manufacturing