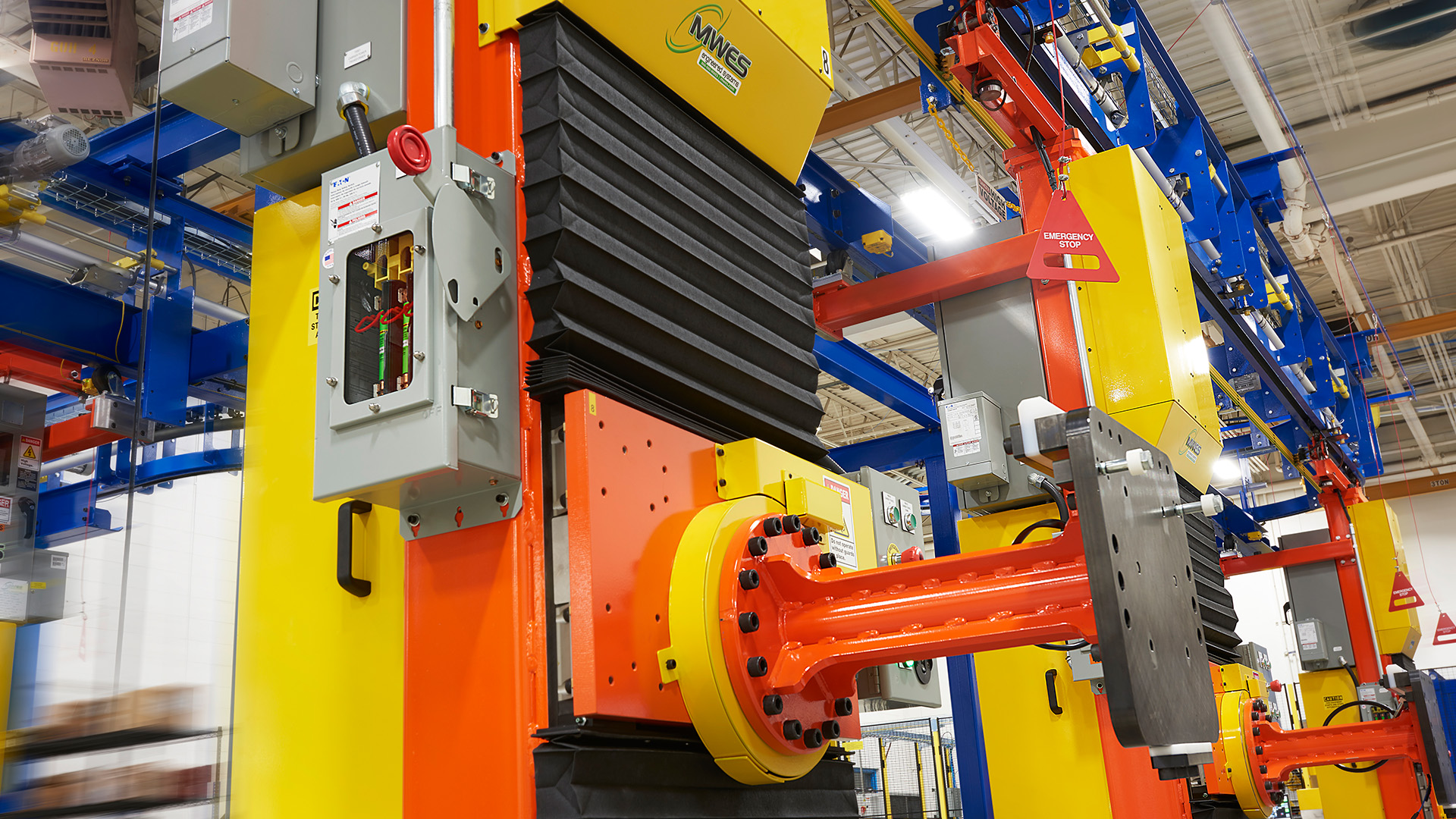

Assembly & Automation

Custom Assembly & Automation Systems That Drive Productivity

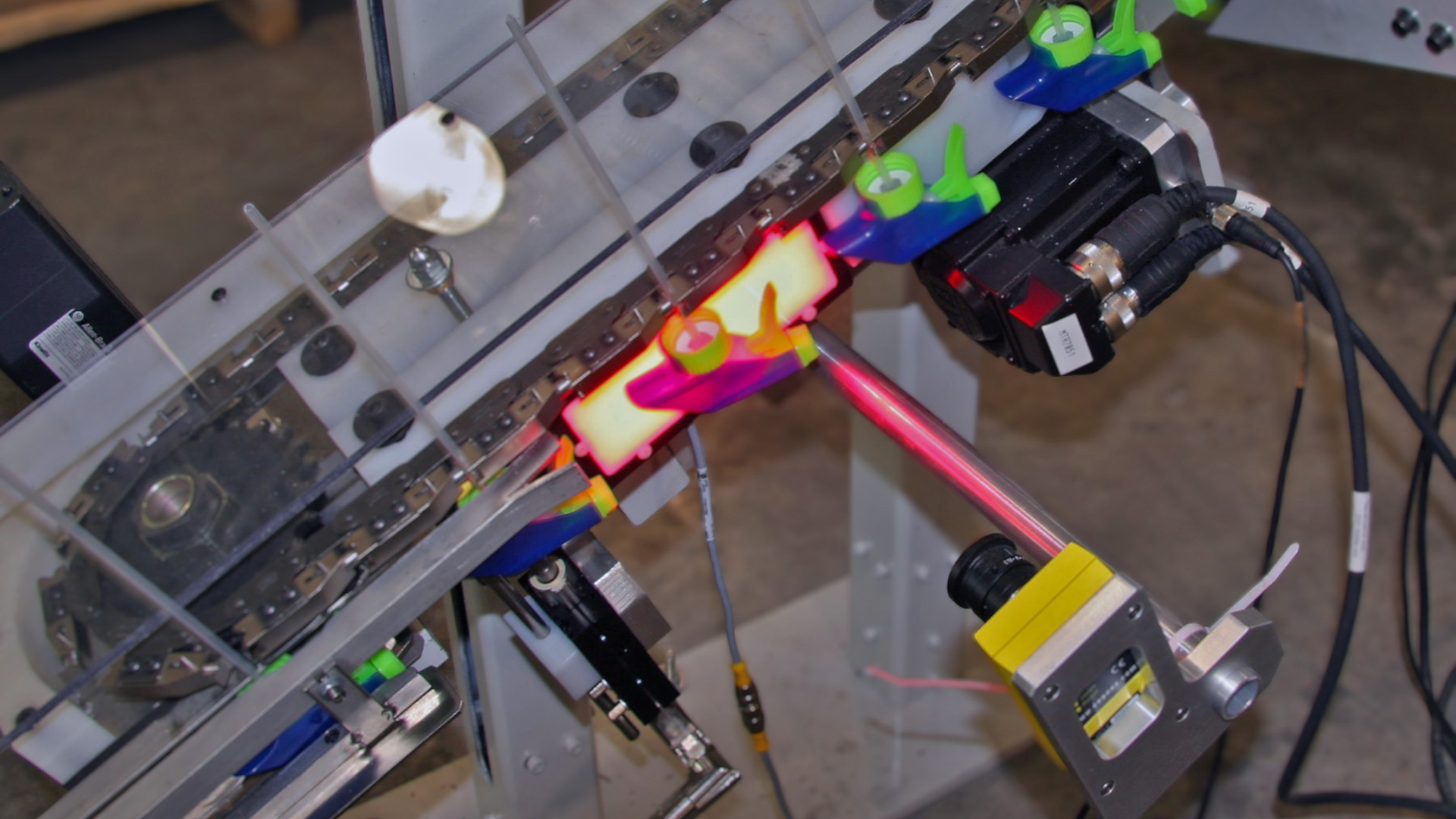

At MWES, we design and build fully integrated automated assembly systems that solve your most demanding production challenges. Whether you’re launching a new product, increasing your throughput, or optimizing an existing process, we deliver purpose-built solutions from concept to commissioning. Our multidisciplinary engineering team—spanning robotics, controls, and mechanical design—applies a data-driven approach that includes Proof of Principle (POP) to validate process capability and ensure robust system performance. By integrating in-line and end-of-line testing strategies, we help manufacturers achieve consistent quality, tighter tolerances, and greater reliability throughout the production lifecycle.

Streamlined

Production

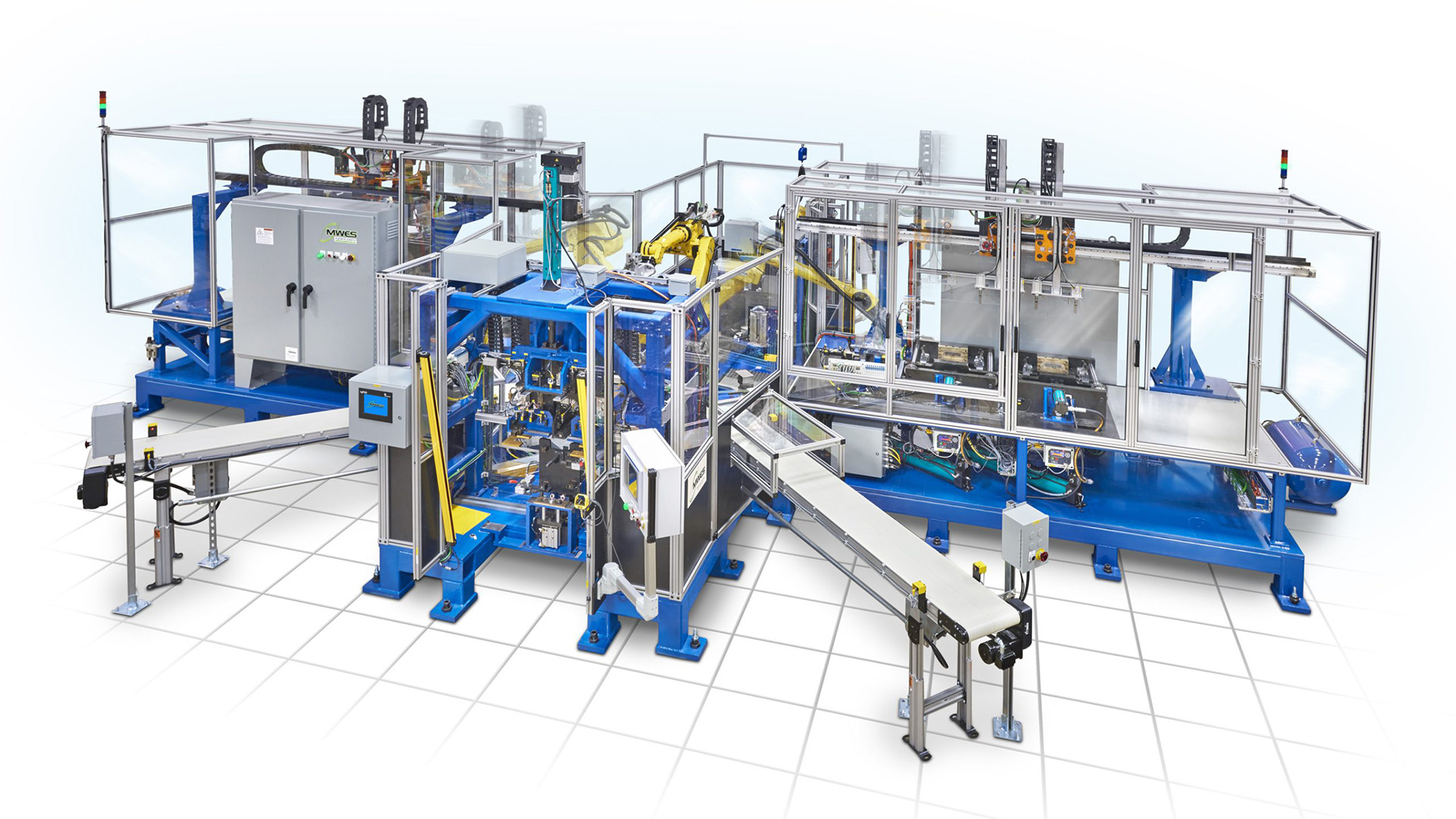

Streamlined Production

Accelerate throughput, reduce cycle times, and eliminate inefficiencies with automation systems engineered to drive consistency and productivity across your entire operation.

Custom-Engineered

for Your Needs

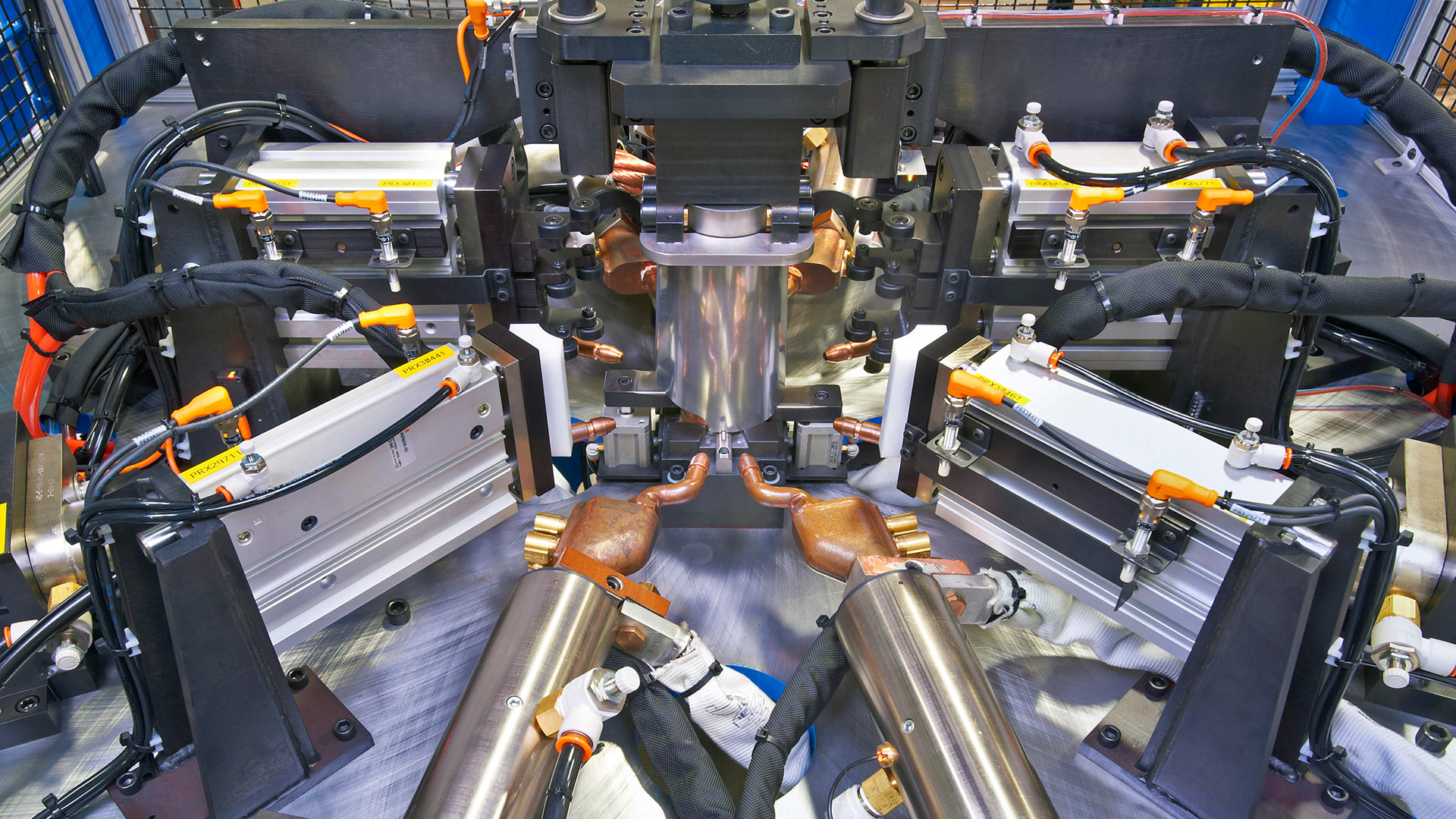

Custom-Engineered for Your Needs

Every MWES solution is designed around your product, your process, and your facility layout. No off-the-shelf compromises—just intelligent, scalable systems built for your exact requirements.

Proven Across

Industries

Proven Across Industries

We’ve successfully delivered automation solutions across industries including automotive, aerospace, consumer goods, military, and food production—earning a reputation for innovation, precision, and long-term value.