MWES Quality Policy

- Home

- MWES Quality Policy

Bringing Our Customers Quality with

Our Commitment to Excellence

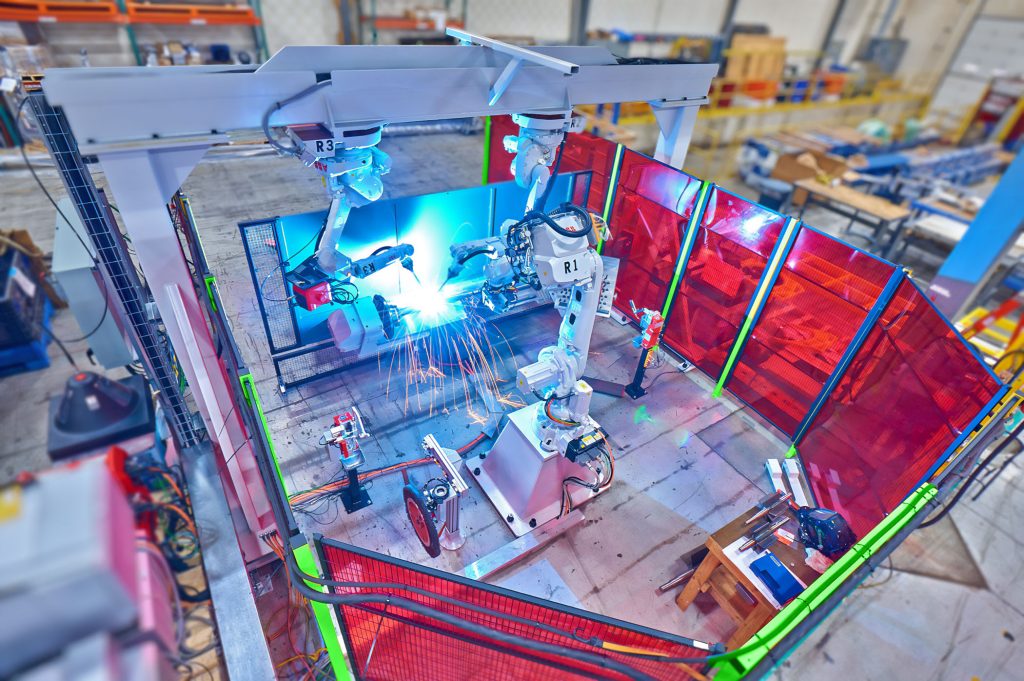

At Midwest Engineered Systems, we are dedicated to delivering exceptional quality in all aspects of our business. Our Quality Management System (QMS) encompasses the design and manufacturing of automated equipment and components for a wide range of industries, including Automotive, Aerospace, Military, Medical, Industrial, and Food.

Scope of Our Management System

Our QMS covers the following areas:

- Design: We meticulously design automated equipment and components to meet the highest standards. Our engineering team ensures that every detail is carefully considered, from functionality to safety.

- Manufacturing: Our state-of-the-art manufacturing processes adhere to rigorous quality control measures. We maintain consistency, precision, and reliability throughout production.

ISO-9001 Compliance

We proudly declare that there are no exclusions from ISO-9001 standards within our organization. Our commitment to quality aligns with the internationally recognized requirements set forth by ISO-9001.

Employee Involvement

Quality is a collective effort. Every employee at Midwest Engineered Systems plays a vital role in maintaining and enhancing our QMS. We foster a culture of continuous improvement, where feedback is valued, and innovation is encouraged.

Core Principles

- Customer Satisfaction: Our customers’ needs drive our actions. We strive to exceed their expectations by delivering products that are reliable, safe, and effective.

- Process Efficiency: We continuously evaluate our processes to eliminate waste, reduce errors, and enhance efficiency. Our goal is to streamline operations while maintaining quality.

- Compliance and Standards: We adhere to all relevant industry standards, regulations, and best practices. Our QMS ensures compliance and drives excellence.

Accountability and Responsibility

We hold ourselves accountable for the quality of our work. Each team member takes pride in contributing to the success of our organization.

Communication

Effective communication is essential for quality. We encourage open dialogue, transparency, and the sharing of best practices across all departments.

Continuous Improvement

Our commitment to quality extends beyond compliance. We actively seek opportunities for improvement, embracing new technologies and methodologies to enhance our products and services.

Reporting Concerns

If you encounter any quality-related issues or have suggestions for improvement, please report them promptly to our Service and Support Team. Your feedback is invaluable in our pursuit of excellence.

MWES brings Innovation through automation

How we can help your business with

The MWES Process

Our Process

With each automation project, Midwest Engineered Systems implements a project management process that walks through the steps for successful equipment integration.

Process Development

Our approach to automation process development is to first evaluate the firm’s current production operation and understand the company’s process needs.

Proof of Principle Testing

We offer the ability to experience the performance of an automation system with real parts and production conditions before significant investment in a production automation system is made.

Consolidating Multi-Line Production

We can utilize our depth of knowledge on facility-wide automation projects to analyze the current production system to build the best automation solution.

Engineering for Manufacturability

We can help reduce the costs associated with automation by analyzing and suggesting product and process modifications.

120+

Team Members

100k+

sq. ft. Facility

4,000+

Systems Built

12+

Years RIA Robot Experts

The Future of Manufacturing