Automatic Stock Coat Robotic Cell

- Home

- Recent Projects

- Automatic Stock Coat Robotic Cell

Project summary

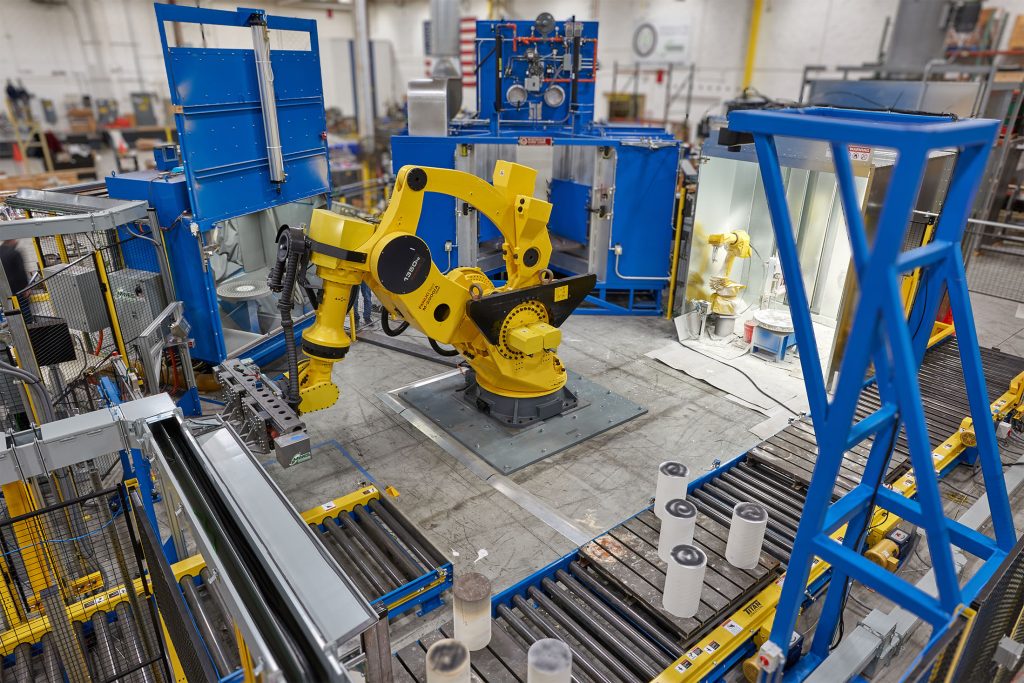

MWES provided this firm with a robotic system that automatically applies Boron Nitride coating to a Nickel base and Titanium alloy stock billets and preforms before they are forged.

The Challenge

Working with large, heavy metal alloy stock parts weighing anywhere from 40 to 1500 lbs. is a difficult process for any manual labor machine tending operations. This firm determined that only a robotic solution could successfully perform these operations. MWES provided this firm with a machine tending robot cell that could easily handle heavy metal stock parts.

The Solution

MWES designed and built a fully automated robotic machine tending cell whose purpose is to apply a Boron Nitride coating to a Nickel base and Titanium alloy stock part before they are moved on to forging. To ensure coating adhesion, each piece must be blasted with Aluminum Oxide grit to roughen the surface of the part. Additionally, each piece must be heated to a specified surface temperature. Finally, the coating will be applied to the complete surface area of the piece at a specified thickness.

The robot cell begins when a pallet of billets is loaded onto the main conveyor by a forklift. The system operator verifies the identity and pattern of the billets and acknowledges them on the main operator station. The pallet is then indexed on the conveyor under a vision camera system which verifies the location of the billets for the robot. The robot picks the billet and places it on a weighing scale where it can be weighed and a laser distance sensor measures the height of the billet.

The robot then picks up the billet and places it in the grit blaster station, the robot picks it up again to reorient the billet to finish the grit blasting process. The billet is picked up and then placed in the oven and once the billet has reached the required temperature, the robot moves it to the coating spray station.

At the coating station, the billet is on a turntable and the part is coated with Boron Nitride on the sides and top. The robot flips the part 180 degrees so the coating can be applied to the remainder of the part. The billet is then picked by the robot and passes the part through a marking station where the part is marked with a barcode. Finally, the robot places the billet on the original pallet on the conveyor line, however, if the part is rejected it is put on the reject conveyor.

Impact to the Customer

The system MWES provided our customer runs at a peak production rate of 7 minutes per part with the average part weight being 400 lbs. The fully automated robot cell handles three completely different part configurations at different weights and dimensions.

Midwest Engineered Systems has a wide range of experience building robotic machine tending solutions. If you want to improve your machine tending throughput, we have the knowledge and experience to make the project successful.

Contact us to learn how Midwest Engineered Systems can automate even your most complex and challenging operations today!

Innovation Through Automation

Client Details

A leader in specialty metal forging for a wide range of industries.