Custom Robot Palletizing Cell

- Home

- Recent Projects

- Custom Robot Palletizing Cell

Project summary

MWES provided a food products manufacturer with a custom-designed compact robotic palletizing cell that can pick multiple cases at once.

The Challenge

Keeping throughput consistent on a palletizing operation can be a huge strain on a manual workforce. Plus dealing with cases that weigh upwards of 40 lbs can lead to worker burnout and insurance claims over time. A leading dairy products producer approached MWES to integrate an automated palletizing solution into one of their facilities to combat worker fatigue and throughput variances.

The Solution

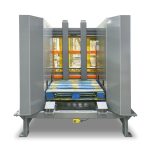

MWES provided our customer with a safe and easy-to-operate fully automated robotic palletizing cell. The cell would receive cases on one of three infeed belt conveyors and, utilizing multiple pallet stacking strategies, palletize three pallets on three separate conveyors simultaneously. The cell also uses an automated empty pallet dispenser that holds 18 Chep pallets to feed the system. A Fanuc industrial robot at the center of the automation is equipped with a custom end effector (EOAT) that can pick multiple cases of mixed sizes weighing up to 40 lbs each. The robot strategically picks anywhere from one to four cases based on the pallet layer pattern.

The automation cell begins with the forklift operator placing a stack of 18 pallets into the pallet dispenser. The pallet dispenser then releases one empty pallet at a time onto the pallet infeed conveyor. The empty pallets are transferred to one of three palletizing conveyors and are stopped at the designated palletizing staging areas. As the empty pallets move into place, the loose cases arrive in the cell on one of three infeed belt conveyors and accumulate at three staging areas.

Once everything is in place the palletizing robot begins picking and placing cases based on a set layer pattern strategy. The robot picks slip sheets from a slip sheet stack to be placed after each layer. The final stack height is based on the individual case sizes. After a pallet has been stacked, it then indexes to the outfeed conveyor where it is transferred to a stretch wrap station and then onto a forklift retrieval station.

Impact to the Customer

The robot palletizing cell MWES integrated for our customer gave them a safe and efficient palletizing process that requires only a single operator to supervise. This allowed them to redirect the other workers to more meaningful duties.

Midwest Engineered Systems has a wide range of experience in building custom robot palletizing cells. If you’re looking to improve your palletizing throughput, we have the knowledge and experience to make the project a success.

Contact us to learn about how Midwest Engineered Systems can automate even your most complex and challenging operations today.

Innovation Through Automation

Client Details

A leading producer of dairy products based in Wisconsin.