Extra Large Bag Making Machine

- Home

- Recent Projects

- Extra Large Bag Making Machine

Project summary

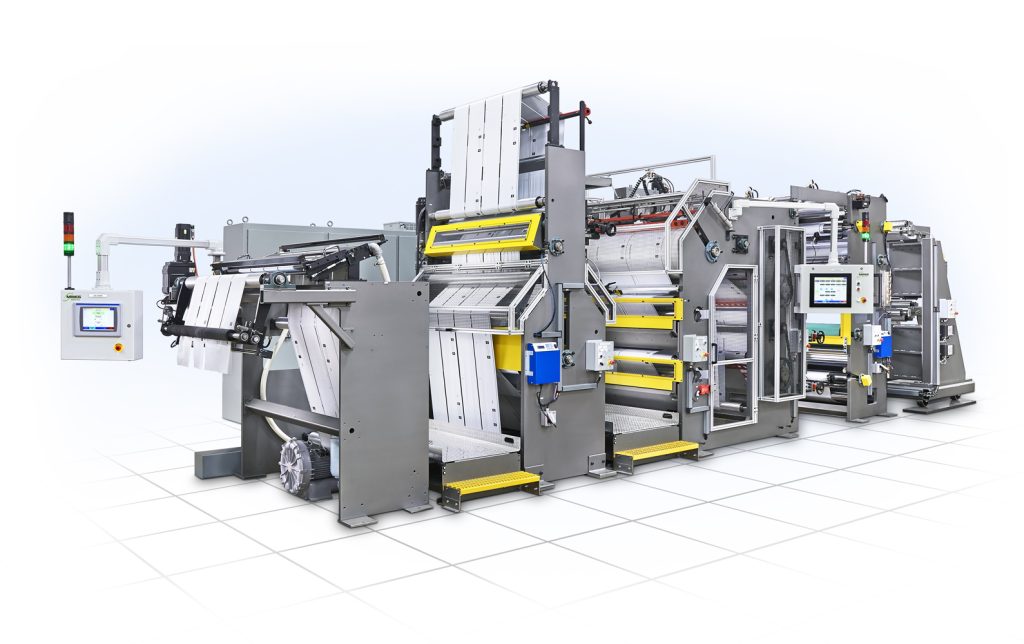

MWES provided this firm with an automated web handling machine that would produce polyethylene packaging bags in a wide range of sizes.

The Challenge

Manufacturing large volumes of polyethylene bags requires complicated web handling equipment to unwind and cut the roll at the defined proportions. This firm sought an automated bag making machine to accommodate a 56-inch wide web running a 1 to 6 mil thick polyethylene sheet. The machine also had to produce different size bags ranging from 8 to 53 inches in width and a minimum of 6 inches long.

The Solution

The web handling system MWES built for our customer is designed to unwind two rolls of film and guide the film through a pair of cut perforation slitters and register the web print together. The web is then nip-fed around a heat sealing drum, which will create a cross-web seal and transfer the web through a pair of servo-driven horizontal perforating knife arrangements. After perforating, the web will be directed over a spreader roll and through a series of heated cut-and-sealing knives to create a separate sealed series of bags. A servo-driven variable-frequency drive (VFD) backup roll will flick the top web to separate the webs and open the bags. The perforated and sealed bags are then placed in dunnage.

The system utilizes an overhead gantry and crane to assist the operator with loading the full rolls into the unwind spindles. Once two rolls are mounted on the unwinders, the films pass through a vertical crush-cut perforation slitter assembly. They are then static pinned together and nipped to the marriage roll. After which the web passes through a third vertical crush-cut perforation slitter assembly that perforates the combined webs. The films pass through a nip assembly, over a load cell roll, and pass vertically down through a punch tooling area. The films proceed back through the rotary web stop unit where it will be able to stop for 1 second.

The films then get nipped against the seal drum and seal the web across the width of the film. The web will then pass in front of a registration sensor and through two rotary perforation units. After the rotary perforation units, the film is fed into the zinger and hot knife assembly. Based on the product being made, the web path can be altered to slit and seal the film into bag sections and then through the zinger roll. The web is nipped against a driven back-up roll and the zinger roll flicks open the bags.

The film passes through a series of hot knives that will slit and seal the bag sides and then the bags pass over a spreader bar. The web then passes in front of the inspection blower box equipped with a banner high-resolution inspection light curtain and then nipped by a draw roll mounted to a pivoting wig-wag arm. Lastly, the perforated and sealed bags are wig wag layer-placed in the dunnage.

Impact to the Customer

The web handling machine that MWES provided our customer produces a variety of plastic bags in different sizes. Depending on the bag size the machine could run up to 93 feet per minute, which produces 42 to 132 bags per minute, and deposit them into containers for further distribution.

Midwest Engineered Systems has a wide range of experience in machines for web handling applications. If you’re looking to improve your web handling throughput, we have the knowledge and experience to make the project a success.

Contact us to learn how Midwest Engineered Systems can automate even your most complex and challenging operations today!

Innovation Through Automation

Client Details

A leading manufacturer of plastic shipping and packaging products, based in Wisconsin.