Robot Depalletizing & Descrambling Cell

- Home

- Recent Projects

- Robot Depalletizing & Descrambling Cell

Project summary

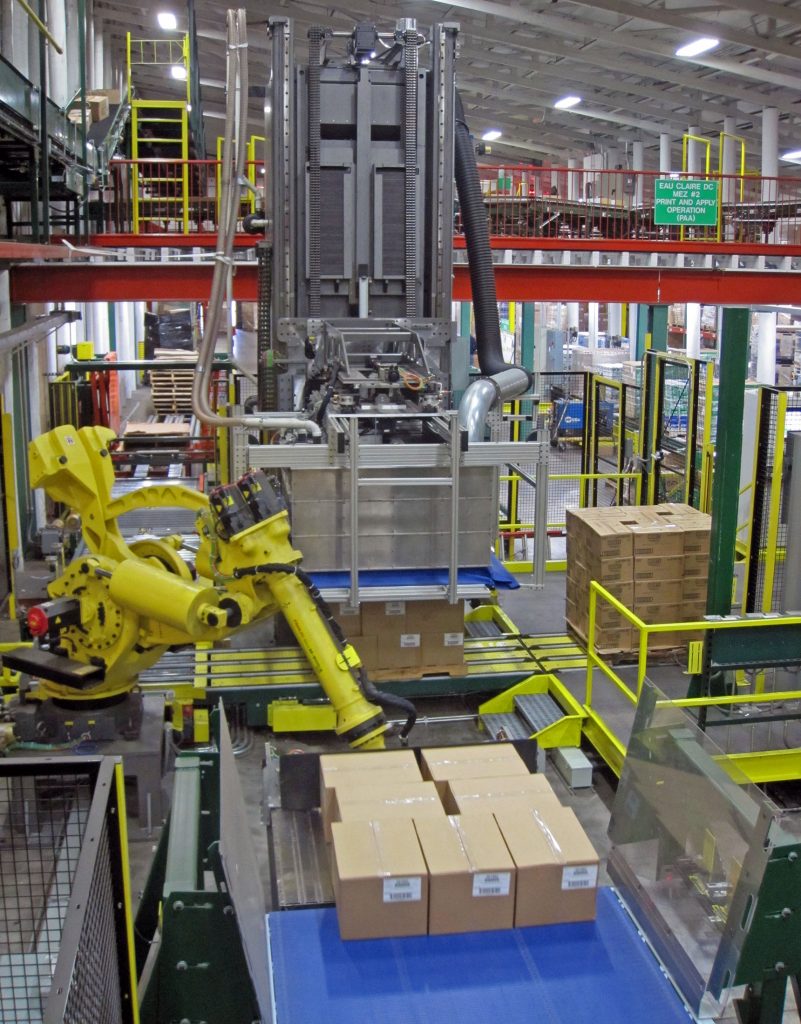

MWES provided this firm with a robotically automated depalletizing and case descrambling system for three distribution centers.

The Challenge

Traditionally when pallets of material arrive at a distribution center, those pallets have to be broken down by workers quickly and efficiently. That process can be labor-intensive, and with labor shortages being commonplace, keeping throughput consistent can be a real challenge. A large national retailer came to MWES looking to automate a depalletizing and descrambling operation robotically. The system had to take incoming pallets that contained stacked boxes of varying dimensions and remove the boxes by layer. The picked layers would be placed on an outgoing conveyor where the boxes would be separated.

The Solution

MWES integrated a fully automated cell that would accept full pallets of cases of varying sizes and pallet patterns. The system picks an entire layer at a time from the infeed pallet and transfers them to the custom outfeed descrambling conveyor. The system utilizes a Schmalz vacuum layer de-stacking system that handles layers up to 54 x 54 inches and 540 lbs. at once and an industrial robot with a custom bottom layer gripper end-of-arm tool (EOAT). The de-stacking gripper can handle case dimensions as small as 6x6x1 inches and as large as 48x25x36 inches.

The pallets will move down the infeed conveyors to the position where the operator removes the packing material or stretch wrap. Using a barcode scanner, the operator would verify the SKU numbers of the products on each pallet layer starting with the top layer down to the bottom layer. If the scanner identifies an SKU that is not in the robotic cell database, the operator shuttles the pallet to a reject conveyor and moves the next pallet onto the station and the operator repeats the process. The conveyor transfers the accepted pallet under the de-stacking and sends a signal to the robot controller that a pallet is in position and ready for robotic de-palletizing. Once the pallet is in position the de-stacking unit will scan the pallet load to ensure the load is relatively square.

The de-stacking vacuum grippers descend to the top of the pallet load where the top grips the layer using a vacuum, a mechanical side grip and the curtain vacuum grips the entire load. Once the layer is secure, the de-stacking tower raises the layer allowing the robot to move in to support the load from the bottom with its bottom layer gripper EOAT. The de-stacking tower releases the layer onto the robot’s EOAT and ascends to clear the product. If a layer slip sheet is present, the robot simultaneously picks the slip sheet below the EOAT.

Lastly, the robot moves the layer to the conveyor drop zone, pushes the contents onto the descrambling conveyor, and moves to the slip sheet deposit station where it releases the slip sheet. Once the pallet is empty, the pallet conveyor moves it to the pallet stacker station and advances the next full pallet to the depalletizing station.

Impact to the Customer

The robot depalletizing and descrambler solution that MWES provided to this customer eliminated a depalletizing operation that at one time would require a fair amount of manual labor to perform. The robot cell gave our customer an average layer to layer pick rate of 15 seconds or four layers a minute and drastically improved their overall depalletizing throughput.

Midwest Engineered Systems has a wide range of experience in building robot palletizing and depalletizing systems. If you’re looking to improve your logistics and fulfillment throughput, we have the knowledge and experience to make the project a success.

Contact us to learn how Midwest Engineered Systems can automate even your most complex and challenging operations today!

Innovation Through Automation

Client Details

Distribution centers for a large national retailer based in Eau Claire, WI.