Robotic Furnace Tending Cell

- Home

- Recent Projects

- Robotic Furnace Tending Cell

Project summary

A steel foundry came to MWES looking to robotically automate a dangerous industrial furnace tending operation that was being performed by manual labor.

The Challenge

Hazardous environments pose a danger to human workers and increase insurance rates for the business. Not only that but finding workers who are willing to operate in such hazardous environments can be challenging. For these reasons, a firm came to Midwest Engineered Systems seeking a solution that would robotically automate an industrial furnace tending operation. The robot automation had to pick up steel shafts, as long as 36 inches, two at a time and load and unload them from a furnace. Ultimately, the entire automation had to service three separate machines: the furnace, the quencher and the temper conveyors.

The Solution

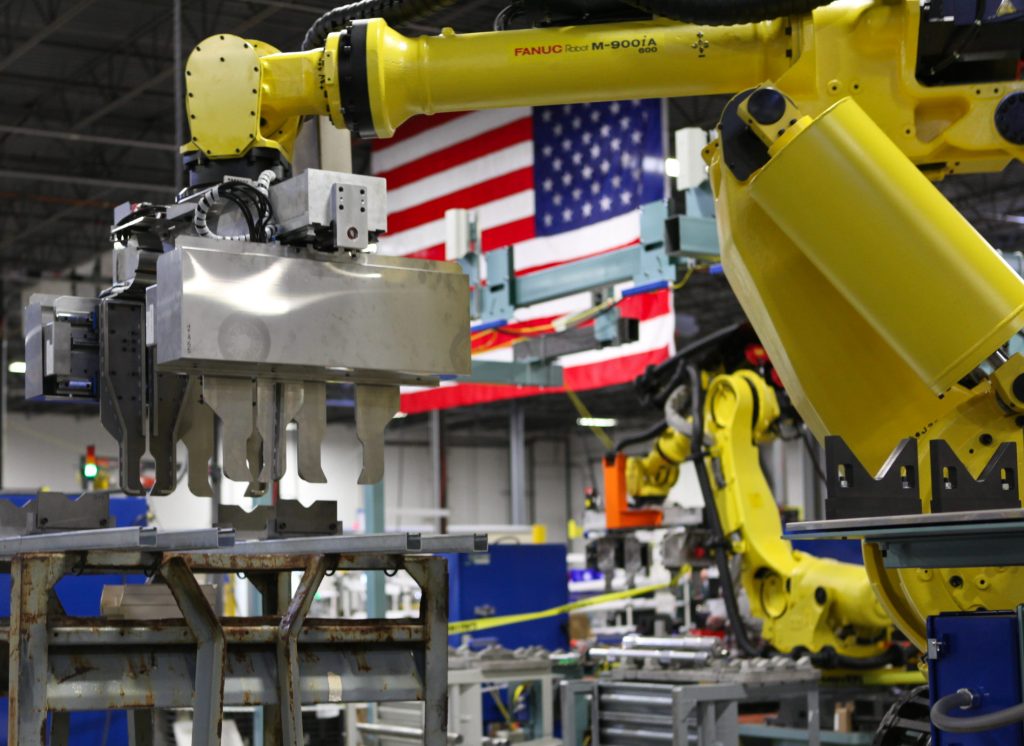

MWES provided our customer with a track-mounted robotic furnace tending cell that loads and unloads steel shafts into a furnace. Additionally, this solution includes processing the shafts through separate quench and temper stations. The provided robotic automation utilizes a Fanuc R-900iA/350 industrial robot that operates on a six-meter travel Floortrack and a stationary Fanuc R-2000iB/210F industrial robot. The stationary robot loads the shafts onto the furnace conveyor. Upon exiting the furnace, the robot on the Floortrack unloads the furnace and proceeds to the quenching conveyor which is followed by the tempering process. The robot unloads the shafts from the temper conveyor and places them on an outgoing conveyor that simultaneously cools the shafts with forced air.

The robot cell begins when the operator loads the steel shafts onto the infeed conveyor and enters the new part number into the system’s HMI. The conveyor indexes the shafts to the furnace load robot. Based on the part number loaded into the HMI, the robot adjusts its EOAT width to accommodate the shaft. The robot then picks a single shaft with its gripper EOAT from the infeed conveyor and places it onto the furnace tray. The tray indexes into the furnace where the heat-treating operation is performed.

Once the tray with the shafts exits the furnace via the conveyor, the robot picks either one or both shafts and transports them to the empty quenching station. At the quenching station, the robot loads the shafts into the quencher. The robot signals the station that the shafts have been loaded and the station’s doors will automatically close. Once the quenching is complete, the station’s doors open and the robot removes the shafts and places them on the incoming conveyor for the temper operation. As the shafts are being tempered, the robot returns to the furnace to retrieve two more shafts and transports them to the quenching station. This cycle repeats until the temper station signals to the robot that the shafts are ready to be unloaded.

The robot returns to the temper station to unload the shafts. It places the shafts in one of the two straighteners. Once the straightening is complete, the robot removes the shafts and places them on a v-block that is mounted on the outgoing feeder. As the completed shafts leave the robot cell they are forced air-cooled to below 150°F to make them safe for the operators to handle.

Impact to the Customer

The robotic furnace tending cell that MWES provided this customer afforded them a furnace operation on steel shafts that is both safe and has consistent throughput. Ultimately, the robot load rate for each station is less than 90 seconds per shaft.

Midwest Engineered Systems has a wide range of experience in building robot machine tending automation. If you’re looking to improve your manufacturing throughput, we have the knowledge and experience to make the project a success.

Contact us to learn how Midwest Engineered Systems can automate even your most complex and challenging operations today!

Innovation Through Automation

Client Details

An off-highway equipment manufacturer and foundry that specializes in the production of steel components.