Robotic Inspection & Packing Automation

- Home

- Recent Projects

- Robotic Inspection & Packing Automation

Project summary

MWES provided a manufacturer of automobile parts with a robotic inspection and packing automation cell for automotive water outlets.

The Challenge

Rapidly and reliably inspecting and packing assembled parts into cases or a layered medium is not an ideal operation for a manual workforce. Moreover, acquiring and retaining enough workers to run that operation for three shifts is a problem in itself. An automobile parts supplier approached MWES seeking a solution to automate that process to keep up with demand.

The Solution

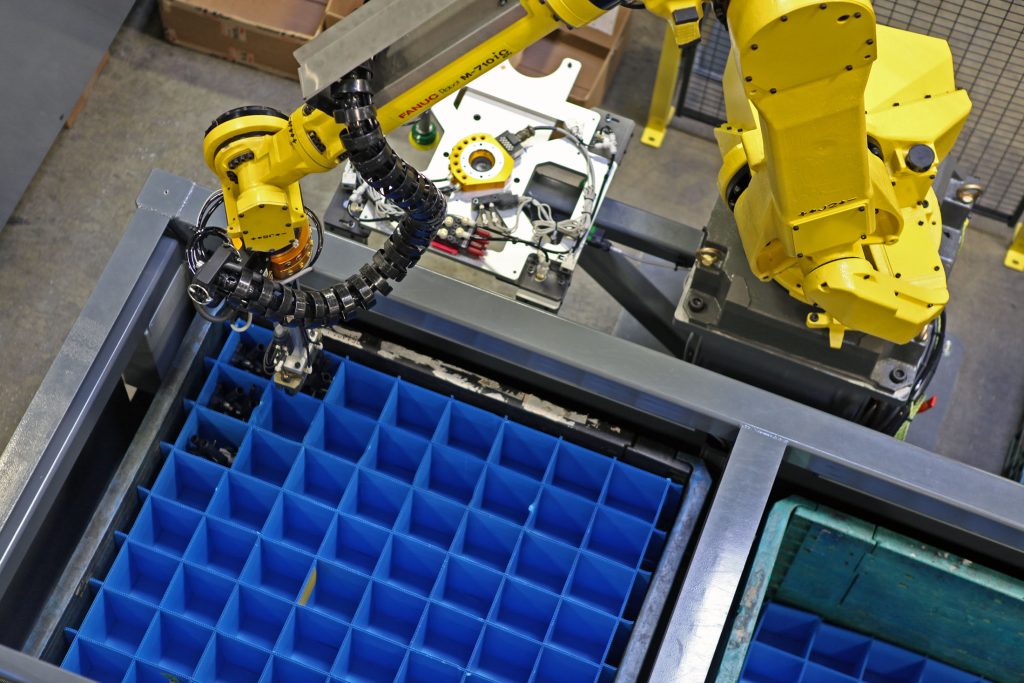

MWES provided our customer with a robotic automation system that degates, inspects, tests and packs water outlets. The system utilizes a Fanuc M710ic/20L robot that is equipped with an integrated 2D vision inspection camera and a tool changer with two grippers: one for handling individual parts and the other for picking the packaging layers. Additionally, the system utilizes an infeed and outfeed conveyor system and packaging Gaylords.

The individual loose parts arrive into the system via an infeed conveyor where the robot using 2D vision picks parts one at a time. It transfers the part to the degate system where the gate is removed and is vision inspected to ensure the gate removal. The robot then transfers the part to the port blockage testing system by loading a part onto one of two load shuttles to accommodate a continuous process flow.

Mechanical probes are then pneumatically inserted into the ports on the part to test blockage. Once complete the tested part shuttles back to the unload position. Based on the test results, the robot places parts that passed into the packaging Gaylord, otherwise, they are placed into the reject bin. Once a layer is full the robot switches tooling and picks an empty layer from the stack and places it over the full one.

Impact to the Customer

The automation system MWES provided our customer with a process that covers three shifts a day and allotted them a cycle time of 25 seconds per part. This process improved their throughput and required only a single operator to supervise the system.

Midwest Engineered Systems has extensive experience in building part inspection and packing automation. If you want to improve your inspection and packing process, we have the knowledge and experience to make the project a success.

Contact us to learn how Midwest Engineered Systems can automate even your most complex and challenging operations today!

Innovation Through Automation

Client Details

A company that specializes in injection molding and prototyping.