Robotic Laser Cutting of Heavy Military Equipment

- Home

- Recent Projects

- Robotic Laser Cutting of Heavy Military Equipment

Project summary

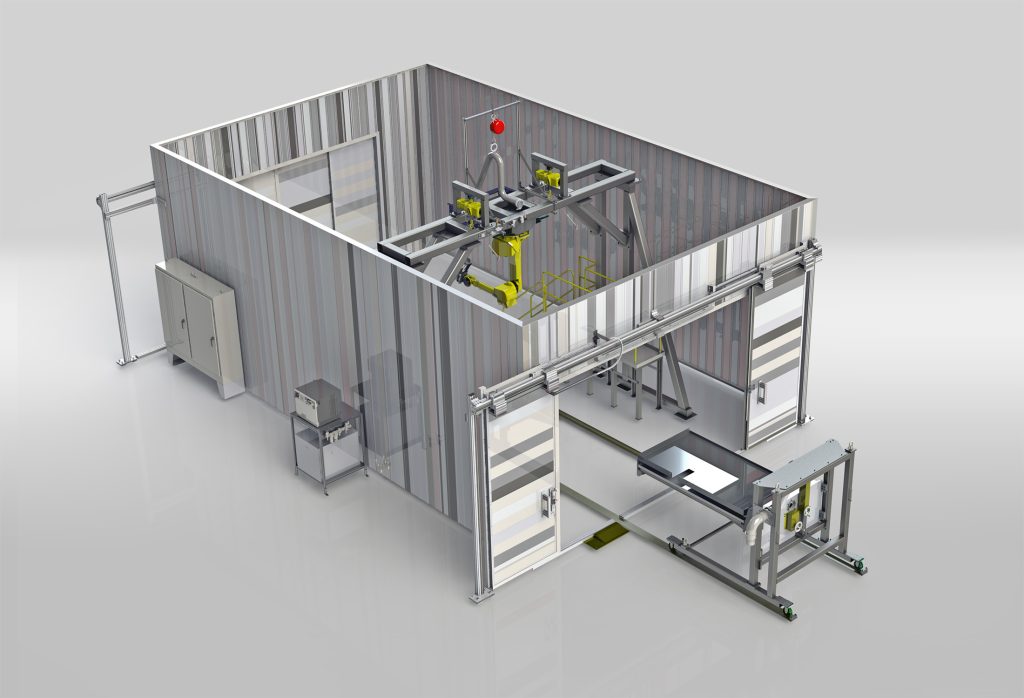

MWES provided a defense contractor with a robotic laser cutting automation cell for modifying heavy armored vehicles.

The Challenge

Modifying large fully built military vehicles is not an easy feat. The military expects their equipment to be ruggedly built and, as such, tend to not be as adaptable to major modifications once built. Additionally, the process had to be performed robotically as manually cutting thick steel is extremely labor intensive and not feasible on a production run. For this project, MWES was challenged with automating a process that required cutting a large rectangular shape and a hole pattern on the thick steel roof of a fleet of armored vehicles.

The Solution

MWES provided our customer with a custom-designed automated robot cutting system that would allow the operator to drive the vehicle into the cell, prep the vehicle for the process and lastly activate the laser cutting robot. The equipment in the cell includes a Fanuc robot with a laser cutting head, exhaust and debris containment system, vehicle floor guiding system and safety system.

The system operator drives the vehicle into the cell, utilizing a painted guide line on the floor and stops when the indicator light turns red. Next the operator prepares vehicle exterior and interior for the laser cutting; which includes positioning the catch pan and exhaust system to the vehicle, attaching the water pump system and filling it with water. Once complete, they will then manually position the cutting template in the cutting zone on top of the vehicle.

The operator exits the cell and selects vehicle search routine on the system’s HMI which starts the automation. The robot utilizes a vision system to seek and locate the template. Once the robot has located the template the operator re-enters the cell and removes the template from the vehicle. After the all clear is given, the robot laser cuts the holes around the top and then the rectangular shape, leaving enough material so that the cut piece does not drop down from the vehicle top. Lastly, the operator enters the cell and removes the laser prep materials; including the catch pan and exhaust system, and drives the vehicle out of the cell.

Impact to the Customer

The efficient and easy-to-operate laser cutting robot automation MWES provided this defense contractor with a total cycle time of 2 hours per vehicle, with the actual cutting time at about 1 hour. This entire operation would not be possible at this scale without robotic automation.

Midwest Engineered Systems has extensive experience building custom systems for military and defense applications. If you want to improve your laser cutting or material removal throughput, we have the knowledge and experience to make the project successful.

Contact us to learn how Midwest Engineered Systems can automate even your most complex and challenging operations today!

Innovation Through Automation

Client Details

A leading military heavy equipment supplier based in Wisconsin.