Robotic Roll Former Tending Cell

- Home

- Recent Projects

- Robotic Roll Former Tending Cell

Project summary

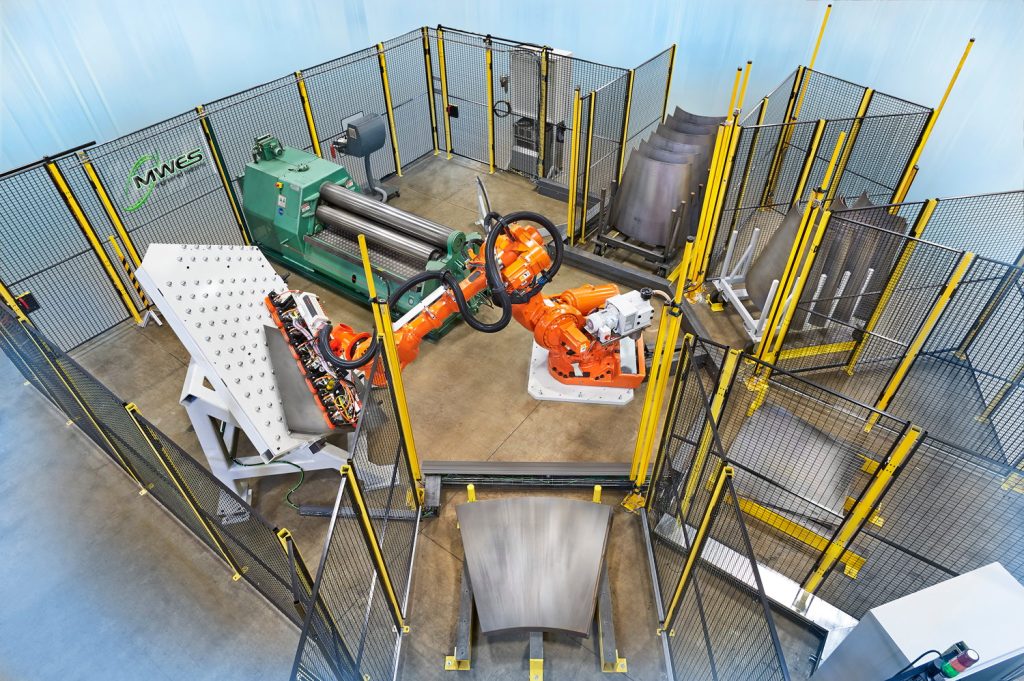

MWES integrated a fully automated robot roll former tending cell for the assembly of steel cones in a production line.

The Challenge

Rolling large, heavy steel plates is a demanding labor-intensive operation for a manual workforce. With labor shortages and the intensity of the work, robotic automation is the only solution for a tending process such as this. For that reason, this firm approached MWES to design and construct a roll forming process that would be robotically automated.

The Solution

MWES provided our customer with a robot cell that would take flat steel cone blanks that weigh as much as 300 lbs. and are as big as 80in x 68in, and run them through a roll forming machine. The robot would be equipped with a vacuum gripper end effector and a re-grip table to square up the parts.

The process would begin as the system operator loads a pallet of steel blanks into the infeed station with a forklift. The robot would then pick a blank off of the pallet and move it to the squaring table. Once the blank has been squared and settled the robot will then regrip the part and would use edge detection sensors to find the exact plane of the leading edge of the part. The robot then communicates with and inserts the blank into the roll forming machine.

Once the roll former has completed its forming operation on the blank, the robot then picks the part from the outfeed side of the roll former. Lastly, the robot will move the completed rolled blank to a rack in the outfeed station where the operator can safely remove the rack once it is full.

Impact to the Customer

MWES provided our customer with a solution to a manufacturing problem that could only be solved with robotic automation. The robotic machine tending cell MWES provided this firm, improved the cycle time of a much larger steel drum production line.

Midwest Engineered Systems has a wide range of experience building robotic machine tending automation. If you’re looking to improve your production line throughput, we have the knowledge and experience to make the project a success.

Contact us to learn how Midwest Engineered Systems can automate even your most complex and challenging operations today!

Innovation Through Automation

Client Details

A large manufacturer of industrial trucks based in Minnesota.