Redefining What’s Possible with Metal 3D Printing

While additive manufacturing has transformed how manufacturers approach part design and production, traditional metal 3D printing platforms often limit size, scale, and application. Large-format metal components still require complex machining, welding, or casting—adding time, cost, and constraints.

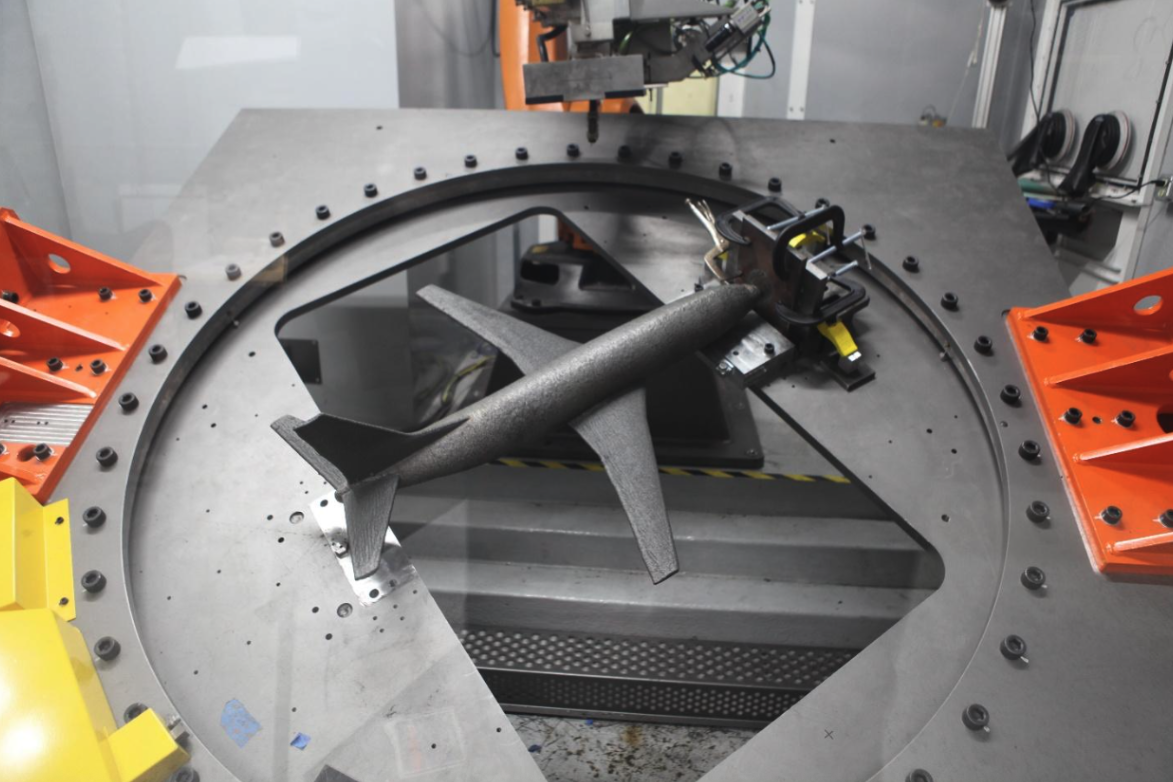

The ADDere™ large metal additive manufacturing process, developed and delivered by MWES, removes those limitations. By combining advanced laser-wire deposition with industrial-scale automation, ADDere enables the production of exceptionally large, complex metal parts at a scale rarely seen in additive manufacturing.

Why Large-Format Metal Additive Matters

Expanded Design Freedom

ADDere technology allows engineers to produce complex geometries, internal features, and optimized structures that are difficult or impossible to achieve with traditional manufacturing methods.

Build Size Without Compromise

Large-format additive systems eliminate the need to fabricate and weld multiple sections together, improving structural integrity while reducing secondary operations.

Industrial-Grade Repeatability

Advanced motion control, thermal management, and process monitoring ensure consistent deposition and repeatable part quality across large builds.

Reduced Lead Times and Material Waste

By eliminating tooling and reducing excess material removal, large metal additive manufacturing shortens lead times and supports more efficient material usage.

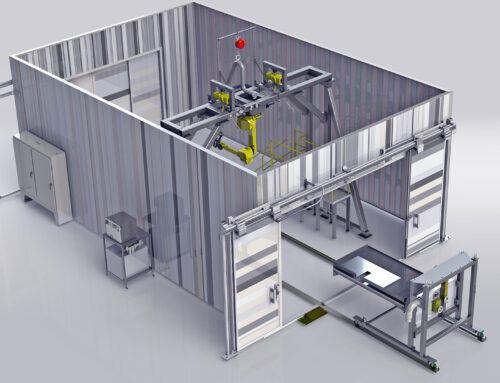

ADDere Systems Built by MWES

MWES designs and delivers ADDere systems that integrate high-power laser-wire deposition, precision motion platforms, automated controls, and safety systems—creating robust, production-ready additive manufacturing solutions for aerospace, defense, energy, and heavy industrial applications.

See ADDere large metal prints at a scale unlike anything seen before—and discover how large-format additive manufacturing can change how you design and build critical components.