Standard Vial Filling Machine

- Home

- Industrial Automation Capabilities

- Robotic Automation Systems

- Vial Filling Automation

- Standard Vial Filling Machine

Standard Vial filling Automation for medical, pharmaceutical & biotech Industries

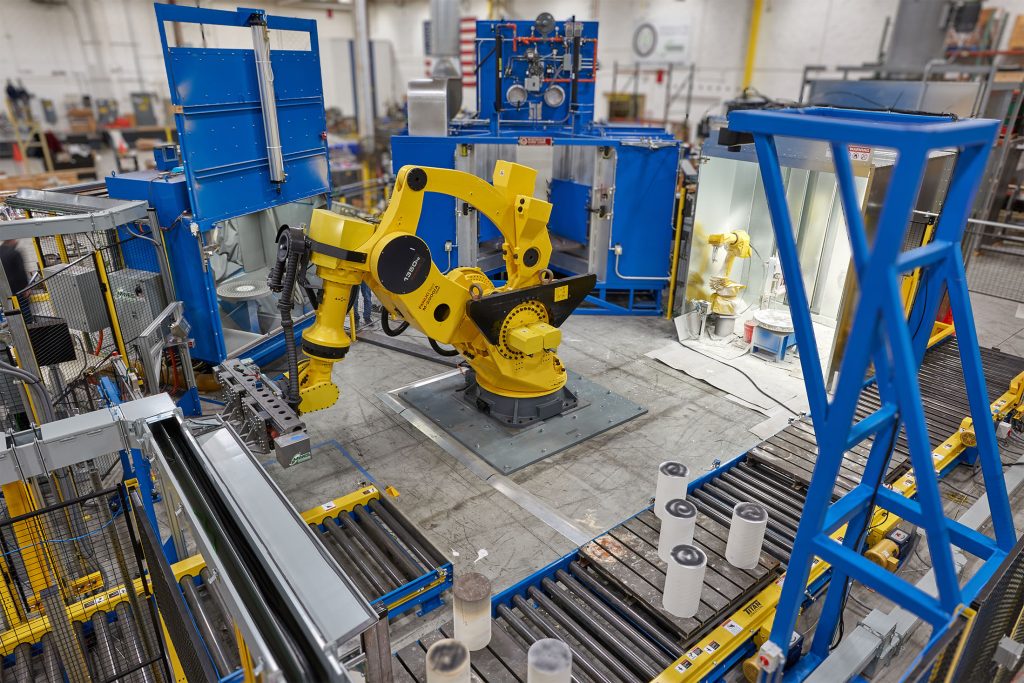

Midwest Engineered Systems provides cost-effective and efficient commercial and clinical standard vial filling automation machine for medical, pharmaceutical, biotechnology and chemical applications. The machine is built with clean room grade materials including bowl feeders that allow for bulk handling of sanitized containers and closures without requiring structured consumable delivery or technician prep. The high-capacity feeders allow for filling automation to operate unattended for far longer amounts of time, letting lab researchers get back to more important tasks.

Midwest Engineered Systems provides cost-effective and efficient commercial and clinical standard vial filling automation machine for medical, pharmaceutical, biotechnology and chemical applications. The machine is built with clean room grade materials including bowl feeders that allow for bulk handling of sanitized containers and closures without requiring structured consumable delivery or technician prep. The high-capacity feeders allow for filling automation to operate unattended for far longer amounts of time, letting lab researchers get back to more important tasks.

Robust programming and the flexibility to modify the machine’s operation easily by non-specialized lab workers further increase the machine’s performance without requiring highly skilled technicians to troubleshoot and change the system for different processes. Increasing product preparation and sample analysis throughput by reducing human intervention is key to our standard machine’s performance.

Standard Vial Filling Machine Features

- Processes up to 17 parts per minute (1,028 parts per hour)

- Exposure time of 5 seconds between vial opening and securing the cap

- Configurable for vials, syringes, T-flasks, bottles or cell-culture dishes

- Handles press-fit, screw cap and crimp close containers

- Safe ISO-5 clean room rated 304 non-passivated stainless steel enclosure

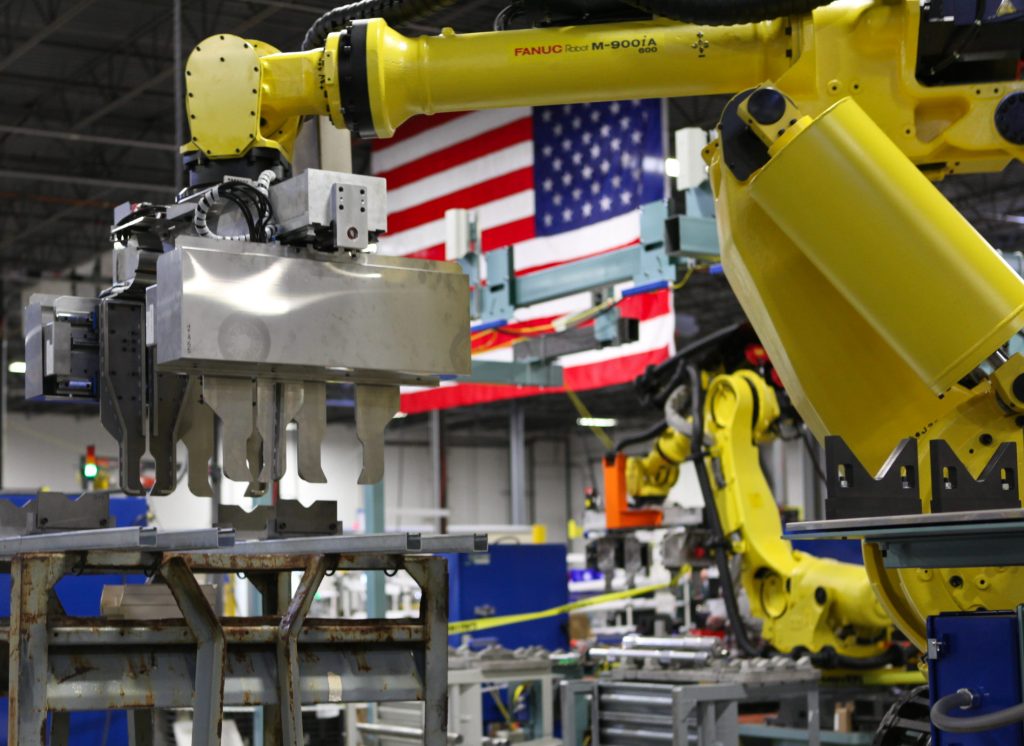

- FANUC LR Mate 200iD/7LC 6-axis Robot with IP67 protection and force sensing gripper

- R-30iB Mate Plus Controller and teach pendant with Estop

- Touch-screen color HMI with Estop push button

Standard Vial Filling Machine Options

MWES can integrate several other additional options for flexibility to enhance the vial filling operation.

- The ability to print serialized samples and batch information directly onto the container as well as to apply information labeling and tamper-resistant materials. This machine-readable labeling allows samples to be easily transferred into other lab processes without human data logging.

- MWES offers several automated closure methods to seal the containers, all of which can happen within the controlled confines of the filling area to reduce exposure to possible contaminates. These closures can also be automatically analyzed for proper containment and seal before leaving the automation cell.

- Additional quality control operations can also be integrated into MWES’s fluid-filling automation machine to ensure each vial meets industry standards. We offer high-precision aseptic filling systems and in-process control packages that determine if the process is within acceptable constraints and can record these values to illustrate trending individually or across batches.

At their core, the MWES standard vial filling machine is designed to get automated sample production up and running as quickly as possible. The filling machine is designed as self-contained unit that can easily fit in current production areas. Once secured, the machine only need connections for power, air and Ethernet. The standard machines can be up and running in as little as a day, allowing your facility to see production gains as quickly as possible.

Building the future of manufacturing, together

The Future of Manufacturing