Why would you want to use robotic automation over manual labor? Simply put robotic automation offers many benefits for your business, such as increased productivity, efficiency, quality, safety and throughput. All of these add up to substantial savings over the long term for any business that deals in manufacturing, assembly, palletizing, picking and packing, warehousing and distribution.

Manual Labor vs. Robotic Automation

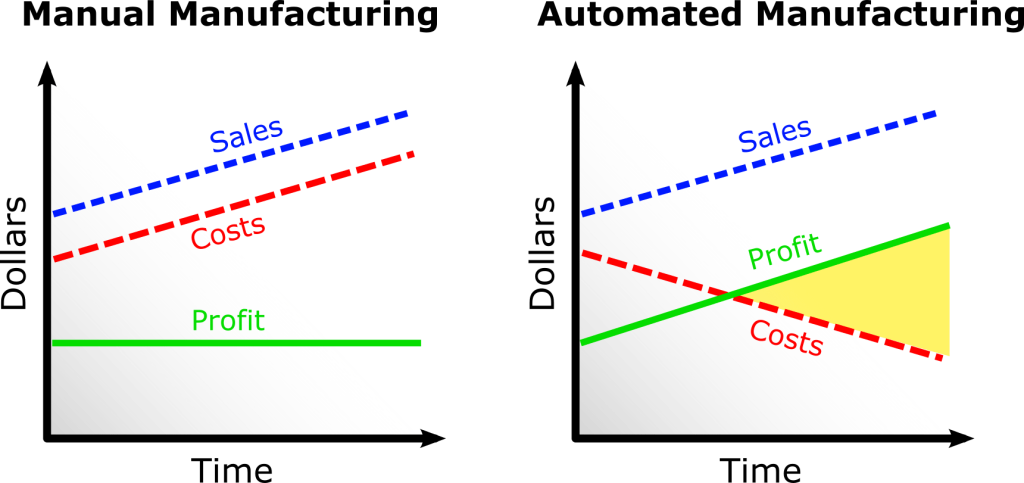

One of the main arguments in favor of robotic automation is that it can reduce the need for costly manual labor, which is often physically demanding, repetitive, dangerous or low-skilled. Manual labor is afflicted by costly injuries or illnesses, mental and physical fatigue, work/home stress, rising wages and work dissatisfaction among laborers. Those points then negatively translate to costly insurance claims, human errors that account for over 20% of unplanned downtime, unavoidable absenteeism, worker turnover along with the cost of onboarding, and finally unpredictable labor shortages. Additionally, the rising costs of employing workers are in the neighborhood of $16 to $30 per hour plus overtime which far outstrips the cost to operate each robot at around $1 per hour. Now, combine with the growing cost of insurance claims and the reported average of 3% of all workers being injured on the job annually, it’s easy to see how robotics can bring down your operations costs in the long run.

As you can see by simply replacing manual labor with robotic automation, your business can improve its performance and competitiveness in the global market with lower costs and consistent manufacturing throughput.

However, the debate between manual labor and robotic automation is not a simple one. There are pros and cons on both sides, and the optimal solution may depend on various factors, such as the type of industry, the nature of work, the level of technology, the availability of skilled labor and the business’s overall future outlook. Robotic automation should not be seen as a threat or a replacement for manual labor, but rather as a complement or a partner that can enhance human capabilities and opportunities, as well as streamline a business’s manufacturing operation.

Calculating your Return-on-Investment

Our return-on-investment (ROI) calculator demonstrates the potential cost savings of using a robotic automation system compared to manual labor operation over a 15-year time period. Our tool factors in the initial cost of the system, the cost of inflation at 2% year-over-year and the year you will break even with a robotic automation system.

Midwest Engineered Systems specializes in a wide range of robotic automation. Whether the automation is in robot welding, material handling, assembly operations, case packing, material removal or general manufacturing automation, we have you covered. Contact us today and speak with one of our Applications Engineers to see how we can improve your existing manual manufacturing operation.